Moving type all-directional feeding platform

A feeding platform, mobile technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problem of lack of feeding equipment in the wall panel rolling production line, and achieve a wide range of applicable products, convenient operation and good versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

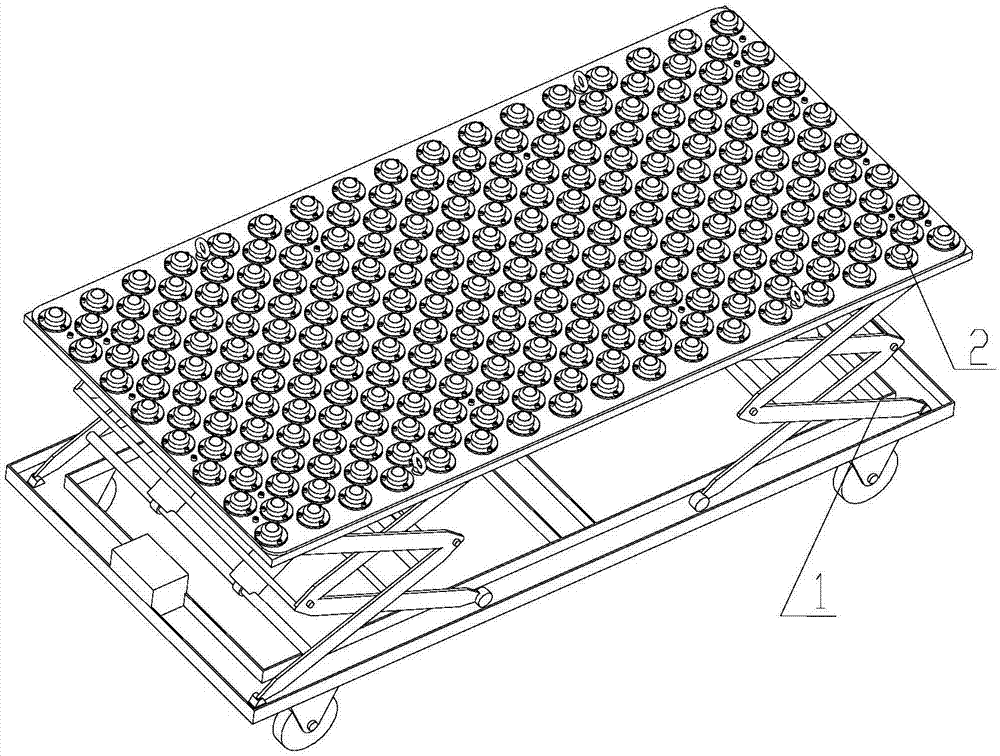

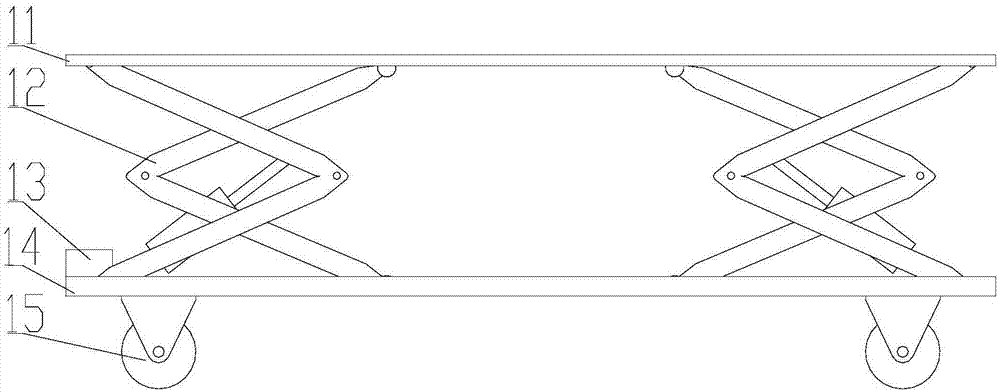

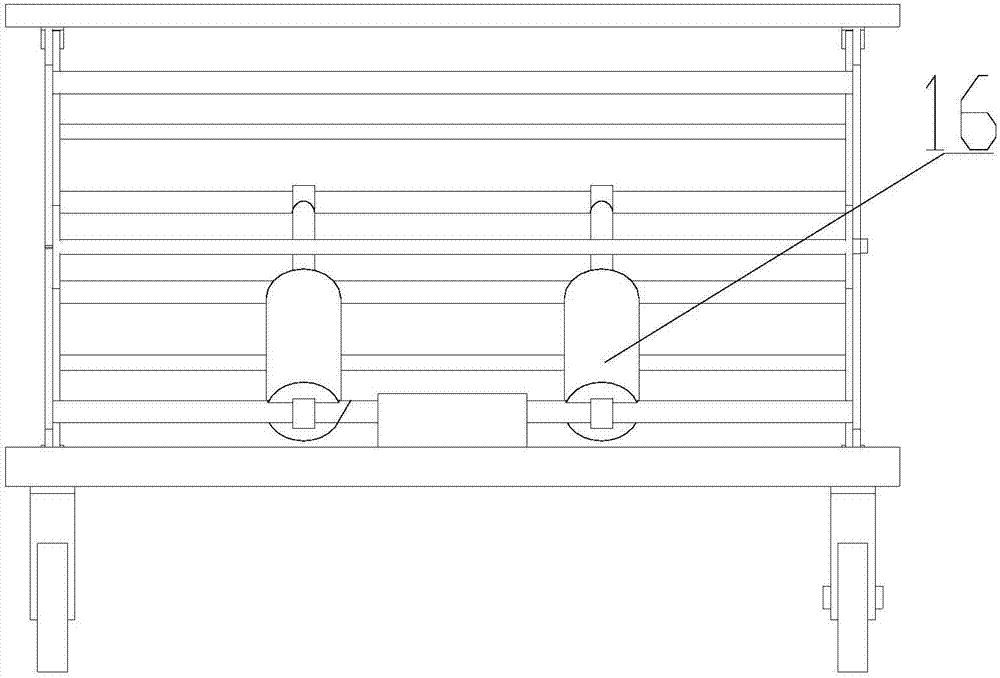

[0016] A mobile omnidirectional feeding platform, such as figure 1 As shown, it includes a mobile hydraulic lifting mechanism 1 and a universal rolling platform 2, and the universal rolling platform 2 is connected above the hydraulic lifting mechanism 1; the mobile hydraulic lifting mechanism 1 is as figure 2 and 3 As shown, including platform 11, scissors 12, hydraulic station 13, car body 14, hydraulic cylinder 16 and four universal brake wheels 15, described platform 11 is positioned at the top of mobile hydraulic lifting mechanism 1, and described scissors 12. The hydraulic station 13 and the hydraulic cylinder 16 are located below the platform 11 and on the vehicle body 14; the structure of the universal rolling platform 2 is as follows Figure 4 As shown, it includes a mounting plate 21 and a universal ball 22, and the universal ball 22 is installed on the mounting plate 21, and the structure of the universal ball 22 is as follows Figure 5 Shown, comprise ball seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com