Bar processing machine tool

A bar processing and machine tool technology, applied in the field of bar processing machine tools, can solve the problems of poor adjustability of the material rack, increase production cost, long waiting time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

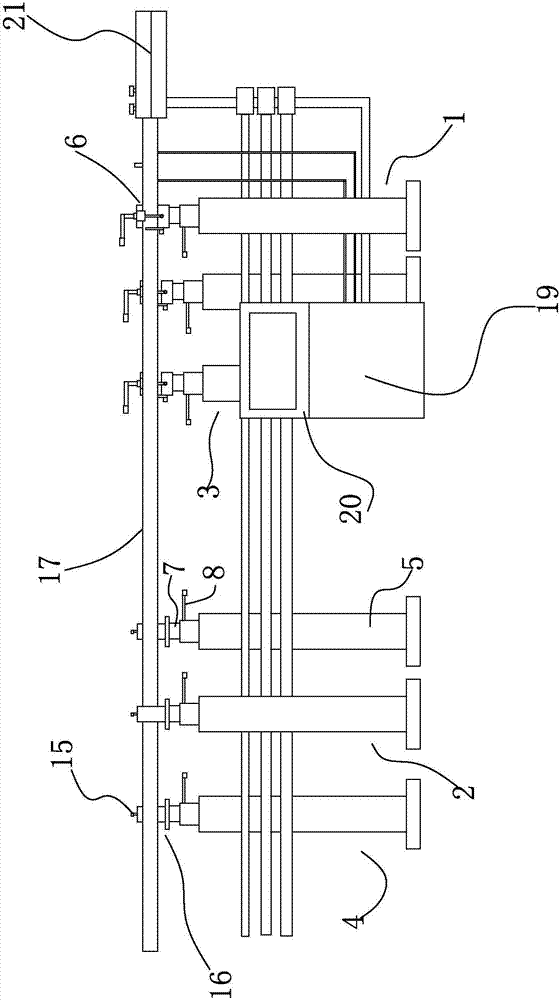

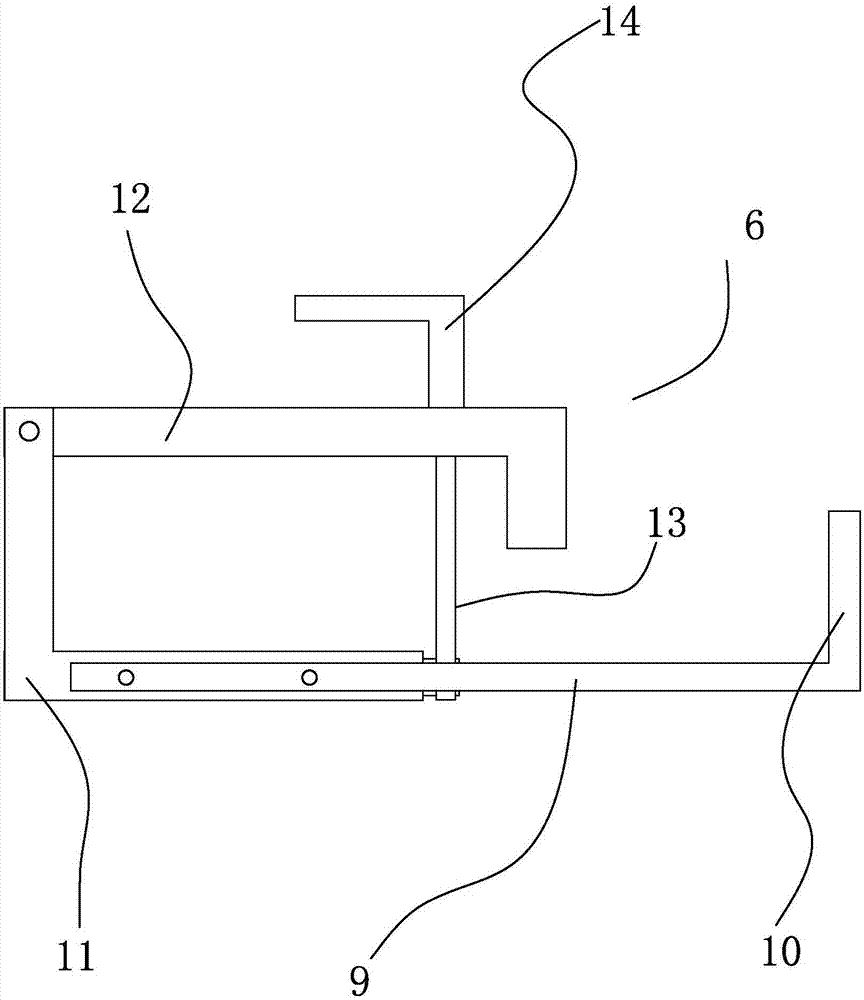

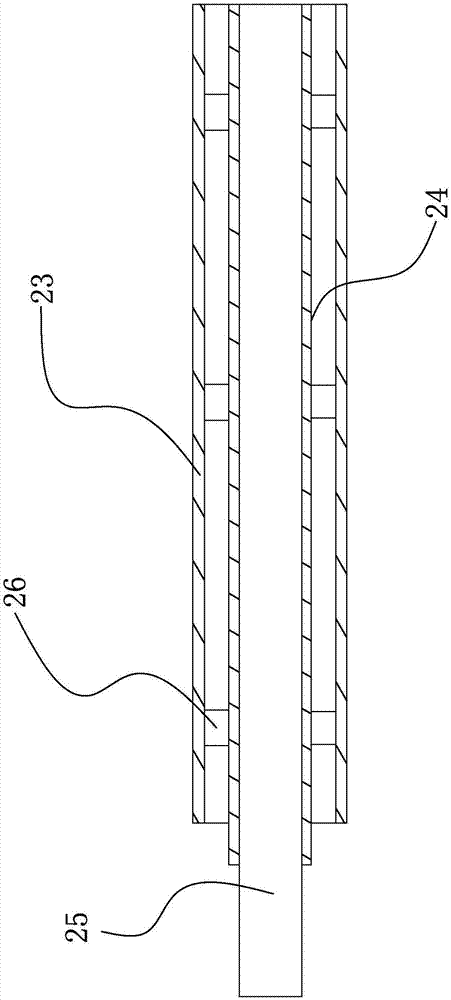

[0016] refer to Figure 1~4 , a bar processing machine tool, comprising a material tube 17, a pre-processing support 1, a post-processing support 2, a loading and unloading front support 3, and a loading and unloading rear support 4, and the material tube 17 is arranged on the processing front support 1, the post-processing support 2, On the front support 3 for loading and unloading and the support 4 after loading and unloading, there are two front support 3 for loading and unloading and two support 4 for rear loading and unloading respectively. , the pre-processing support 1 and the post-processing support 2 support and clamp the material tube 17, process the bar material discharged from the material tube 17, and on the other hand, install another material tube 17 with the bar material Clamped to one of the front brackets 3 for loading and unloading and the bracket 4 for loading and unloading, the front bracket 3 for loading and unloading and the rear bracket 4 for loading an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com