Car door-frame weatherstrip

A technology for sealing strips and door frames, which is used in sealing devices, engine sealing, vehicle parts, etc., can solve the problems of complex structure, large frictional resistance and poor elasticity of sealing strips, prolong service life and sealing performance, improve elasticity and stability. Strength, effect of superior chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

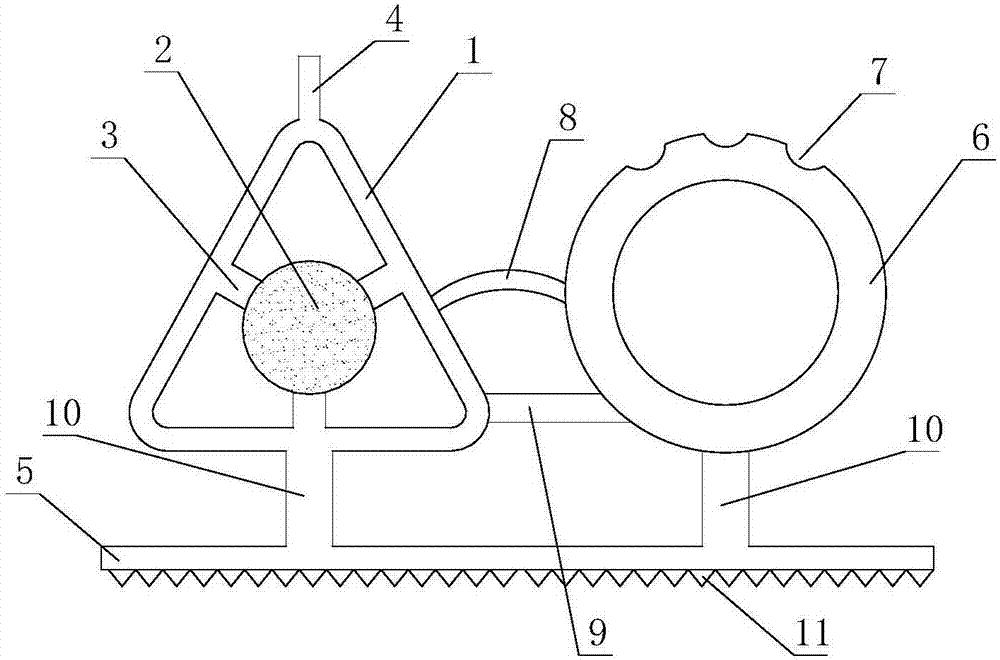

[0014] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0015] Such as figure 1 The automobile door frame sealing strip shown includes a lower rubber skin 5, on which a first sealing assembly and a second sealing assembly are respectively installed through two support parts 10, and the first sealing assembly includes a first rubber skin 1 , the first rubber skin 1 is a triangular hollow tube, the inner cavity of the first rubber skin 1 is provided with a sponge inner core 2, and the inner wall of the first rubber skin 1 is integrally formed with a bracket 3 supporting the sponge inner core 2; the second sealing assembly includes a circular Ring-shaped second rubber skin 6, the upper part of the second rubber skin 6 is provided with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap