High efficiency packaging machine for toilet paper production

A high-efficiency, paper-drawing technology, which is applied in the field of balers, can solve the problems that the internal components of the baler body cannot be effectively dissipated, the first servo motor and fan blade are not installed, and the baler body cannot be conveniently installed, so as to improve physical and mental health. , Safe and convenient to use, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

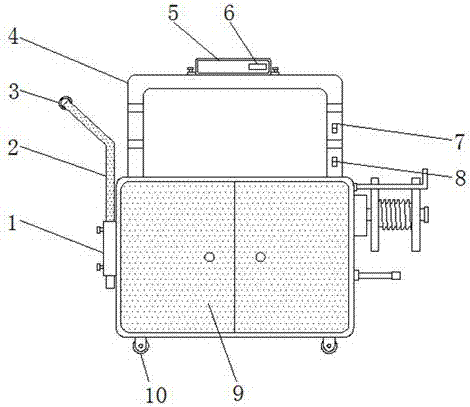

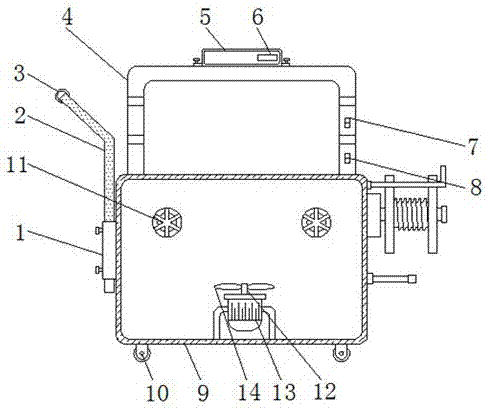

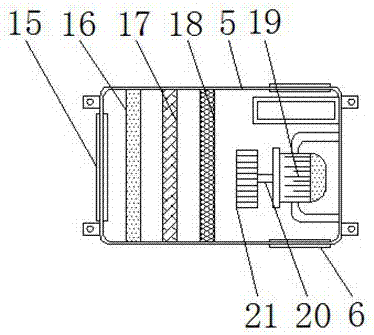

[0018] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a high-efficiency baler for paper pumping production, including a sleeve 1, a push rod 2, a handle 3, a cross bar 4, an air cleaner 5, an outlet 6, and a first switch 7. Second switch 8, baler body 9, pulley 10, heat dissipation window 11, first rotating shaft 12, first servo motor 13, fan blade 14, inlet 15, primary filter 16, photocatalyst filter 17, activated carbon filter 18. The second servo motor 19, the second rotating shaft 20 and the impeller 21, the bottom end of the baler body 9 is provided with a pulley 10, and the top of the baler body 9 is provided with a cross bar 4, and one side of the baler body 9 is provided with a Push rod 2, and the inside of the baler body 9 is provided with a first servo motor 13, the bottom end of the push rod 2 is covered with a sleeve 1 near the side wall of the baler body 9, and the top end of the push rod 2 is covered with a handle 3 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com