Cleaning and drying device for anti-smog textile cloth

A drying device and textile cloth technology, which is applied in the direction of textiles and papermaking, textile material processing, textile material carrier processing, etc., can solve the problems of reducing cloth washing times, human injury, chemical raw material residues, etc., and achieve improved cleaning and drying Efficiency, prevention of dust adsorption, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

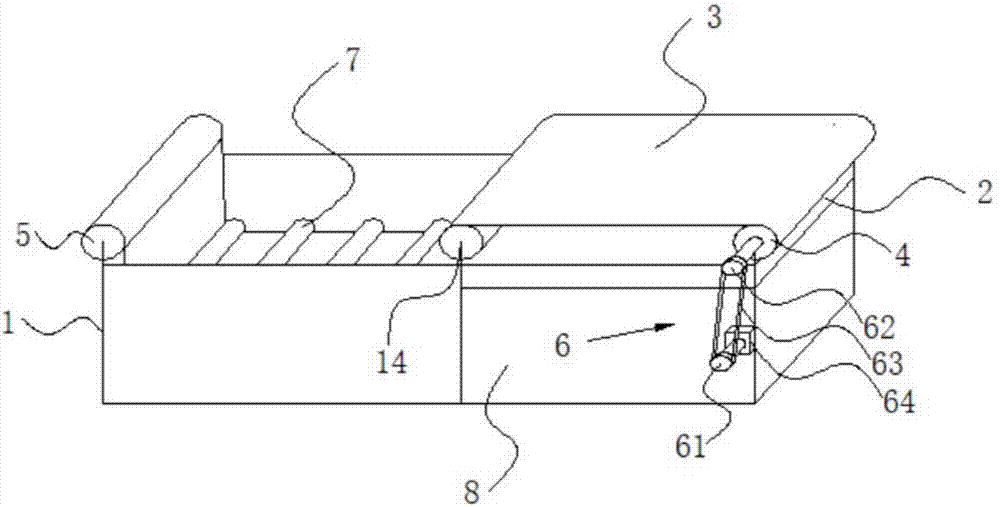

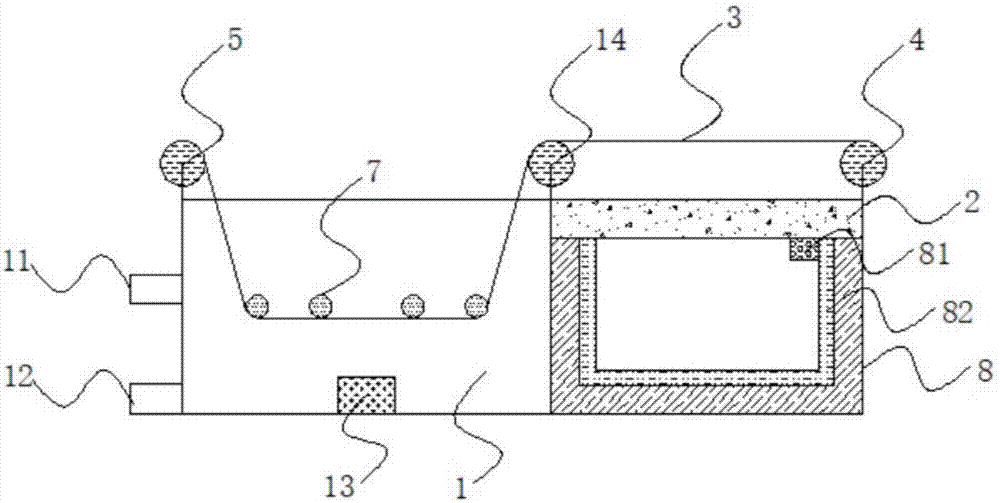

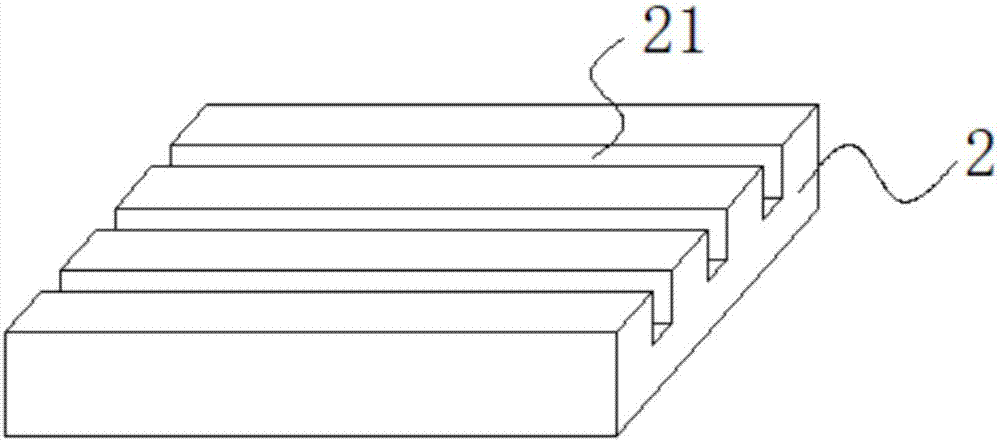

[0020] Example: An anti-fog textile cloth cleaning and drying device, such as Figure 1-Figure 3 As shown, the washing tank 1 and the drying plate 2 are included. The conveying direction of the anti-fog textile cloth 3 is defined as the front. The front and rear sides of the washing and drying device are respectively provided with a film-receiving drum 4 and a film-releasing drum 5, After passing through the washing tank 1 and the drying plate 2, the anti-fog textile cloth 3 of the film releasing drum 5 is connected to the film collecting drum 4, and one end of the film collecting drum 4 is provided with a driving device The driving mechanism 6 for the rotation of the film drum 4;

[0021] The cleaning tank 1 is provided with a plurality of cloth guide rollers 7, and the cloth guide rollers 7 are arranged along the left and right directions of the cleaning tank 1 and the distance between the adjacent cloth guide rollers 7 is equal. The roller 7 is located in the cleaning liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com