Stacked cobweb composite filter paper for separating emulsified water from fuel oil and preparation method of stacked cobweb composite filter paper

A technology of emulsified water and cobwebs, applied in separation methods, chemical instruments and methods, filter paper, etc., can solve the problems of small fuel flux, poor separation performance of emulsified water, and low separation efficiency, and achieve large fuel flux and low thickness , the effect of high separation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a stacked spider web composite filter paper for separating emulsified water in fuel oil, the specific steps are:

[0034] The first step: dissolving lithium chloride in N, N-dimethylformamide solvent, the mass percentage of lithium chloride is 0.5%, so that it is fully dissolved; dissolving polyvinylidene fluoride powder in the above solution , heated in a water bath at 80° C. for 8 hours, and stirred on a magnetic stirrer for 24 hours to form a homogeneous and stable low-viscosity solution, and the mass percentage of the polyvinylidene fluoride was 0.1%. The surface tension of the low-viscosity solution is 20mN / m, the viscosity is 0.1mPa·s, and the conductivity is 0.01mS / cm;

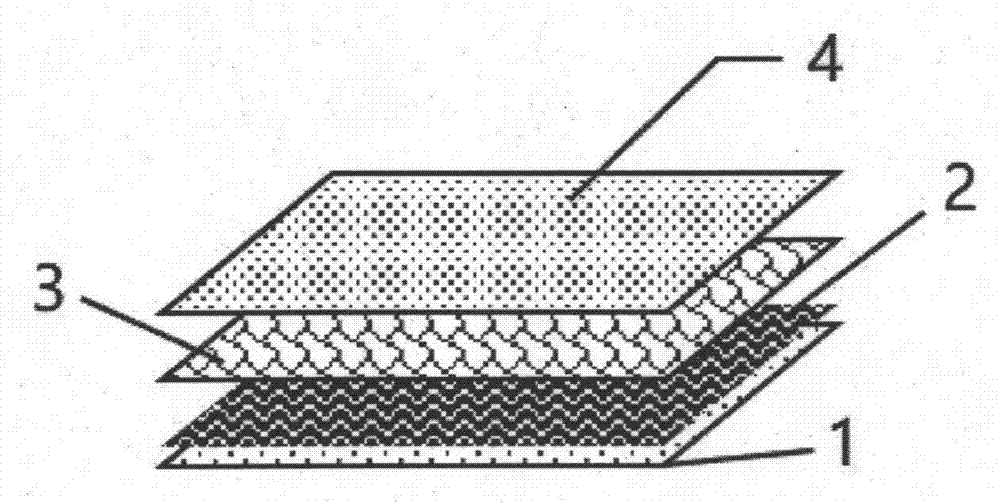

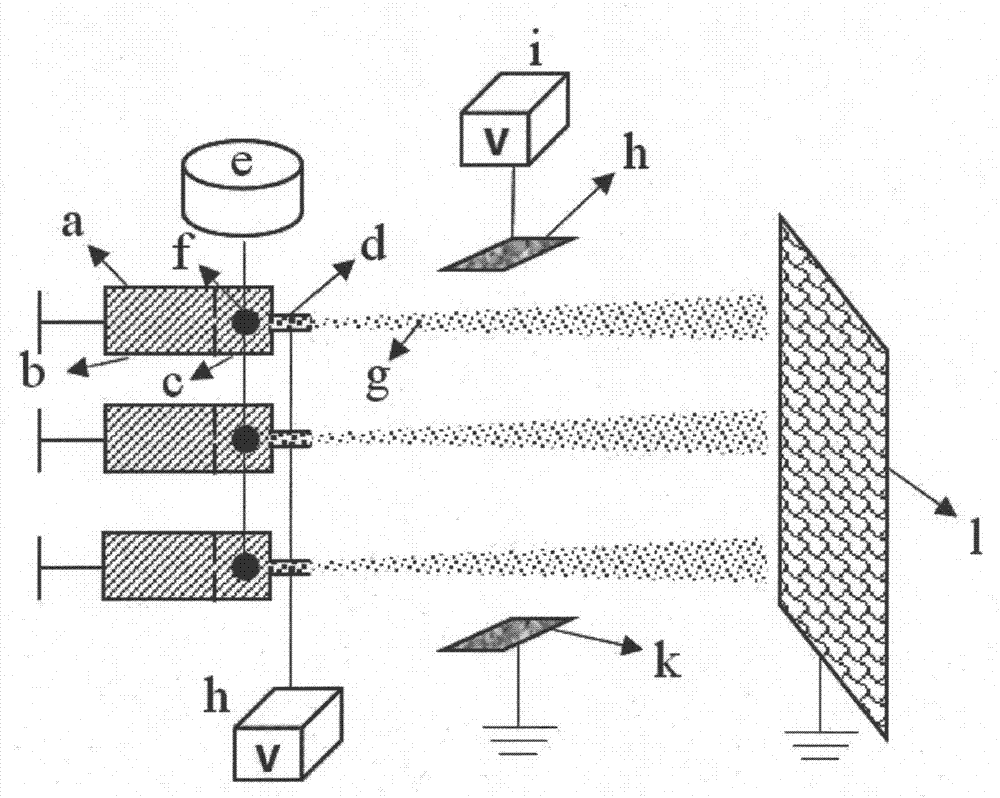

[0035] Step Two: Use figure 1 In the spider web direct injection device shown, the receiving substrate is polyvinylidene fluoride nanofiber-coated paper base, the paper base is hydrophobic modified cellulose fiber filter paper, and the air permeability is 50L m -2 ·s -1 ...

Embodiment 2

[0039] A method for preparing a stacked spider web composite filter paper for separating emulsified water in fuel oil, the specific steps are:

[0040] The first step: dissolving potassium chloride in N,N-dimethylacetamide solvent, the mass percentage of the potassium chloride is 10%, so that it is fully dissolved; dissolving polysulfone particles in the above solution, 70 °C in a water bath for 3 hours, and placed on a magnetic stirrer to stir for 18 hours to form a homogeneous and stable low-viscosity solution. The mass percentage of the polysulfone is 1.2%. The surface tension of the low-viscosity solution is 26mN / m, the viscosity is 96mPa·s, and the conductivity is 5.5mS / cm;

[0041] Step Two: Use figure 1 In the spider web direct injection device shown, the receiving substrate is polyvinylidene fluoride nanofiber-coated paper base, the paper base is hydrophobic modified cellulose fiber / chemical fiber filter paper, and the air permeability of the paper base is 200L m -2 ...

Embodiment 3

[0045] A method for preparing a stacked spider web composite filter paper for separating emulsified water in fuel oil, the specific steps are:

[0046] The first step: dissolving magnesium chloride in the mixed solvent of N,N-dimethylformyl / acetone (m / m=7 / 3), the mass percentage of the magnesium chloride is 9%, so that it is fully dissolved; the poly Styrene particles were dissolved in the above solution, heated in a water bath at 55° C. for 4 hours, and stirred on a magnetic stirrer for 18 hours to form a homogeneous and stable low-viscosity solution. The mass percentage of polystyrene was 0.9%. The surface tension of the low-viscosity solution is 46mN / m, the viscosity is 98mPa·s, and the conductivity is 12mS / cm;

[0047] Step Two: Use figure 1 In the spider web direct injection device shown, the receiving substrate is polystyrene nanofiber-coated paper base, the paper base is hydrophobic modified cellulose fiber / chemical fiber filter paper, and the air permeability is 200L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com