Installing device of residential PC prefabricated part and installing method of PC prefabricated part

A technology for prefabricated components and houses, applied in the direction of building components, building structure, building materials processing, etc., can solve the problems of personal safety impact, low adjustment efficiency, spending a lot of time, etc., to ensure personal safety and improve installation efficiency. , the effect of reducing construction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

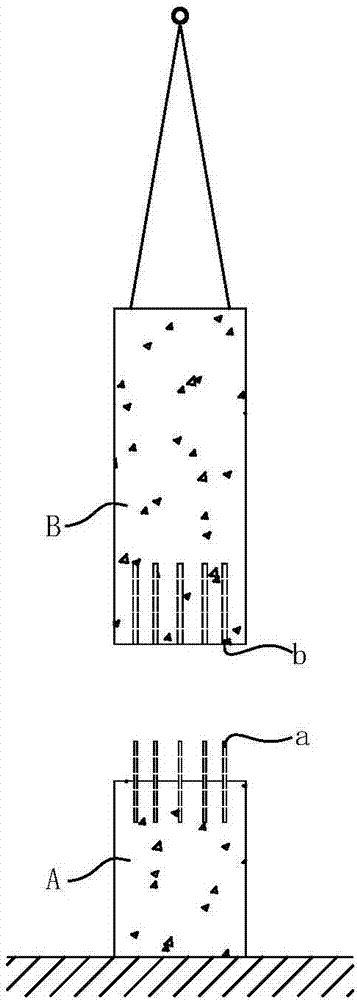

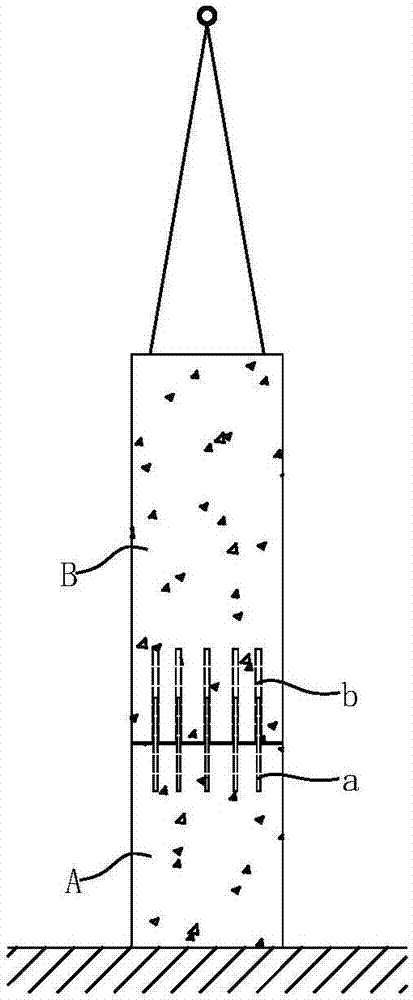

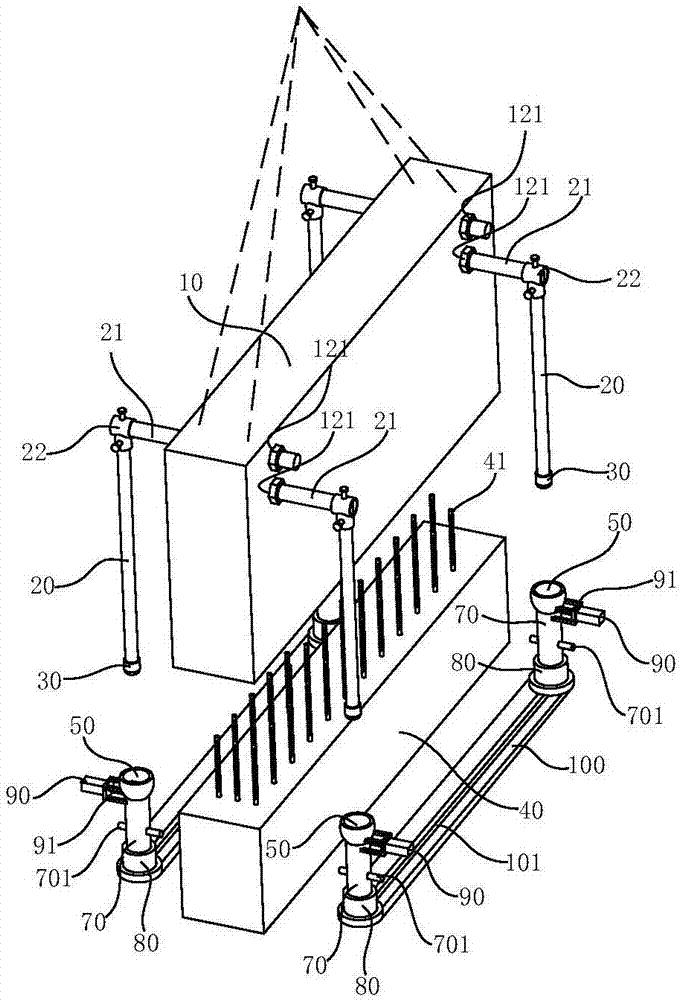

[0012] combine Figure 1 to Figure 6 , the present invention is further described:

[0013] The installation aid for residential PC prefabricated components includes a vertical bar 20 arranged on the preassembled PC prefabricated component 10, and the vertical bar 20 is detachably connected to the preassembled PC prefabricated component 10. The lower end of the vertical bar 20 is at least Three sets of positioning heads 30 are provided. The positioning heads 30 have a hemispherical structure and their lower end faces are in the same plane. A positioning bowl 50 corresponding to the position of the positioning heads 30 is provided on the side of the basic PC prefabricated component 40 on the ground. The diameter of the mouth of the positioning bowl 50 coincides with the maximum size of the positioning head 30, the diameter of the bottom of the positioning bowl 50 coincides with the diameter of the lower end of the positioning head 30, and the bottom of the positioning bowl 50 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com