Air intake joint structure of double-cylinder engine

An air intake joint and engine technology, applied in engine components, machines/engines, fuel air intakes, etc., can solve the problems of complexity, low space utilization, poor smoothness of air intake of two-cylinder engines, and achieve scientific design, The effect of saving assembly space and compact air intake arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

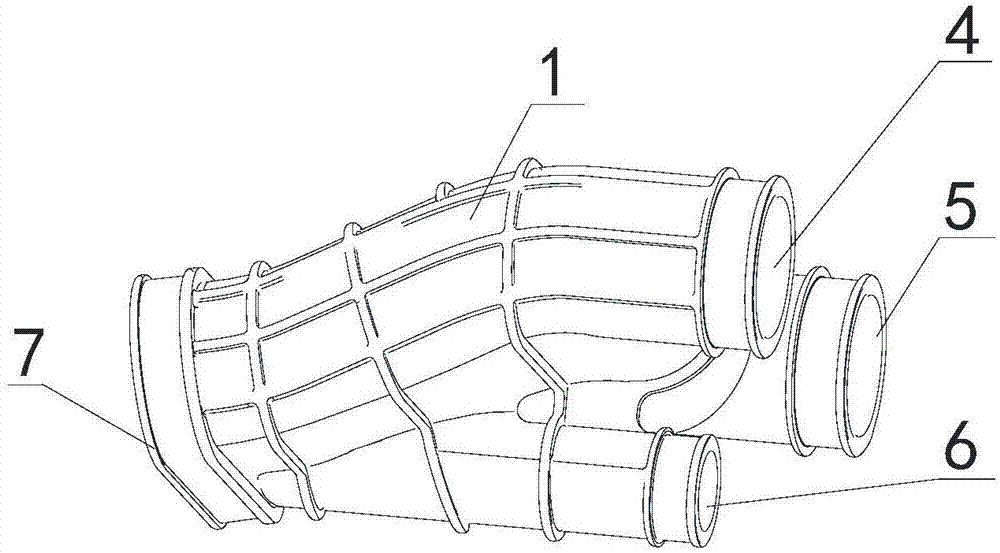

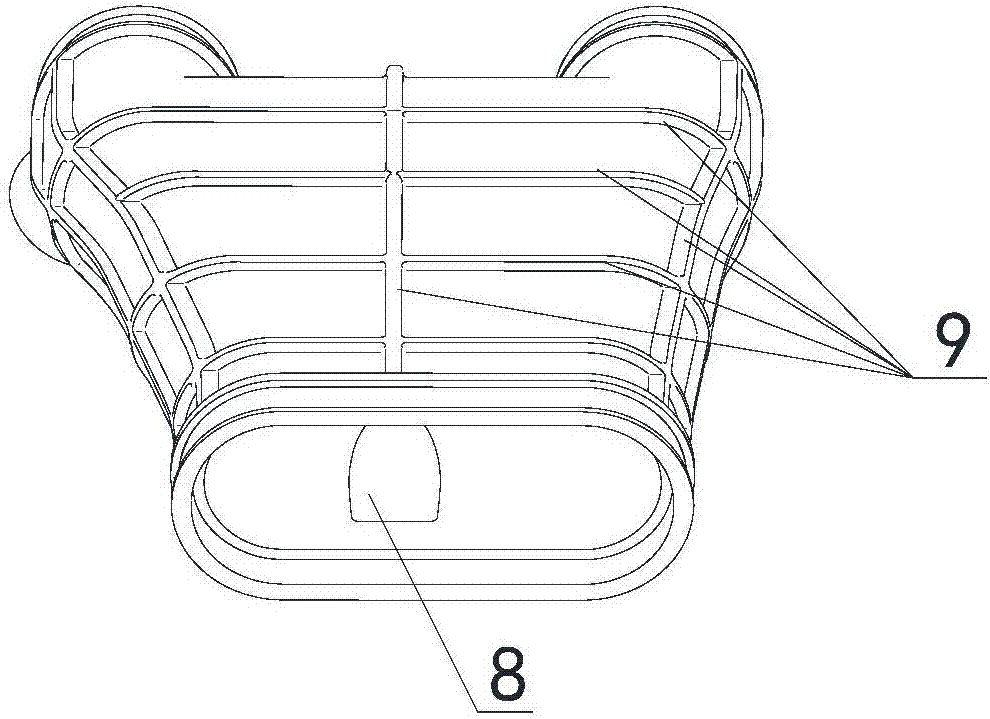

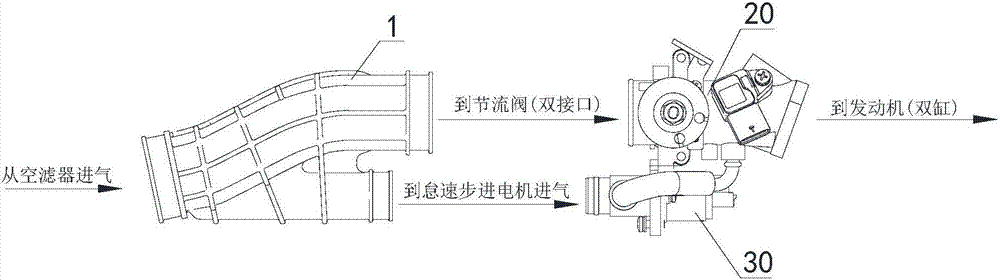

[0015] a kind of like figure 1 , figure 2 , image 3 The air intake joint structure of the two-cylinder engine includes an air intake joint body 1 connected between the air filter, the engine throttle valve 20 and the idle speed stepper motor 30, and one end of the air intake joint body 1 has a connection with the air filter. The other end of the intake joint body 1 has a second interface 4, a third interface 5 and The fourth interface 6, wherein the second interface 4 and the third interface 5 are correspondingly connected to the two throttle valve throats of the engine throttle valve 20, and the fourth interface 6 is connected to the intake throat of the idle speed stepper motor 30 .

[0016] Specifically, the entire air intake joint body 1 is integrally formed, which can not only meet the air supply requirements for the two cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com