Integrated technology of city coal gas coproducing methanol

A technology for the synthesis of city gas and methanol, which is applied in the petroleum industry, the manufacture of combustible gas, and the mitigation of joint combustion, to achieve the effects of stable operation, saving construction investment and reducing land occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

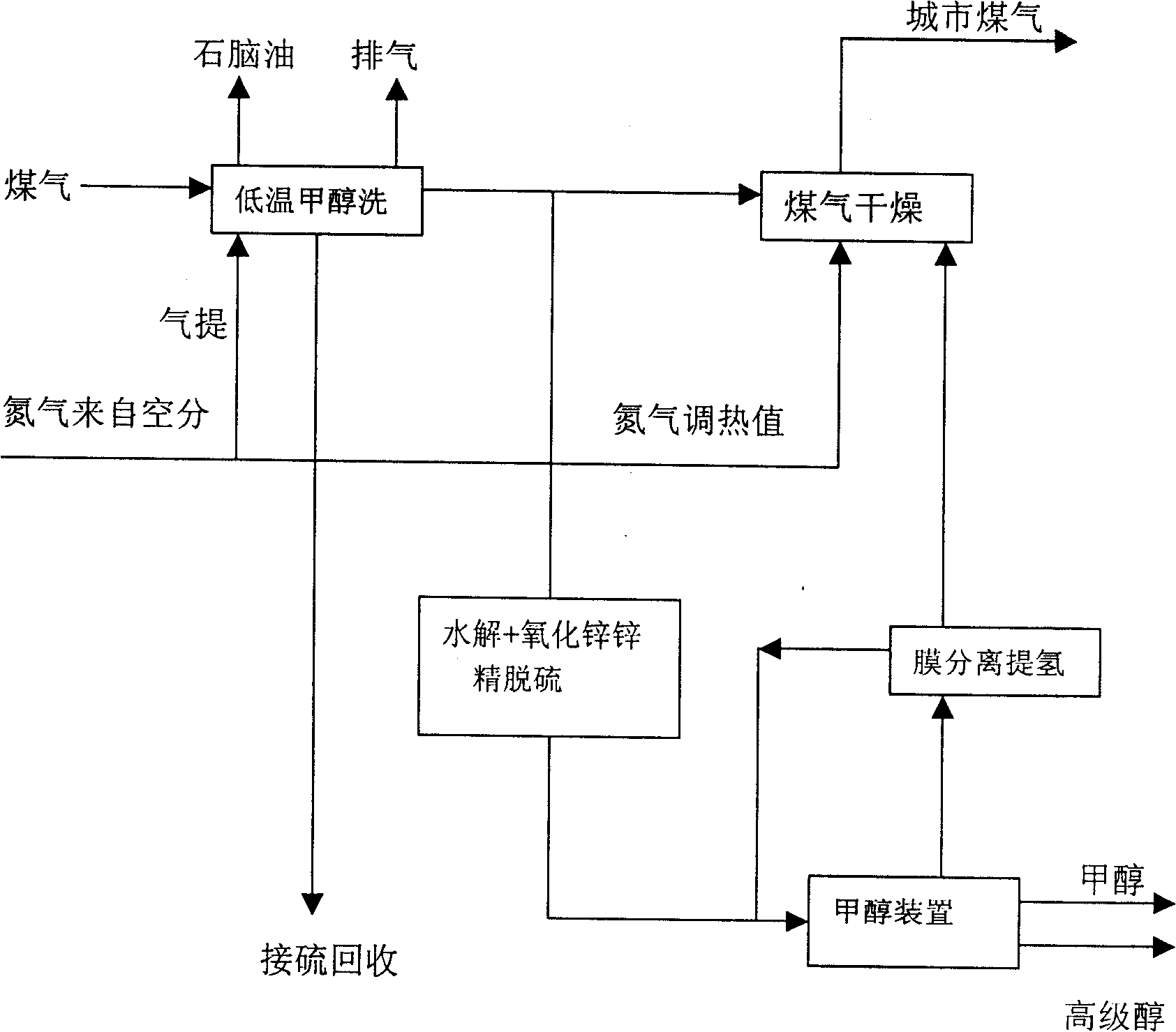

Image

Examples

Embodiment Construction

[0017] For better illustration of the present invention, by comparing with the technique of pure coal-to-gas production methanol, give examples as follows:

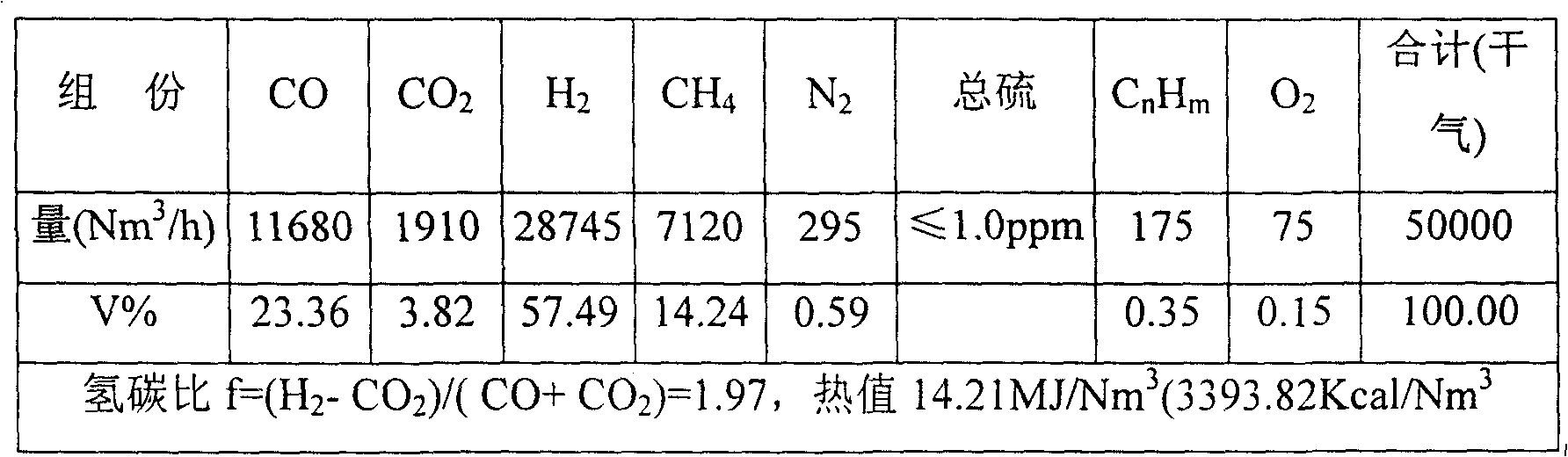

[0018] The invention adopts fixed-bed pressurized gasification, low-temperature methanol washing and purification, and gas water treatment production technology, and meets the following requirements of city gas supply: city gas supply with wide applicability of coal types, gas calorific value and carbon monoxide content complying with national regulations Standards and devices can operate safely and stably for a long period of time. The net gas composition and gas volume after washing with low-temperature methanol are:

[0019]

[0020] Daily supply of city gas (maximum) 91×10 4 N m 3 , calorific value 14.69MJ / Nm 3 (3510Kcal / Nm 3 ).

[0021] Simultaneous production of methanol:

[0022] (1) Methanol synthesis process

[0023] Adopt technological measures of increasing feed gas intake, reducing circulating gas vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com