Novel high-pressure pump tappet

A high-pressure pump, a new type of technology, used in fuel injection pumps, engine components, machines/engines, etc., can solve the problems of damage to the cylinder block and guide sleeve, stress concentration, high cost of the tappet, and simplify the manufacturing process and assembly process. Reduce the risk of deformation of parts and the effect of firm and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below through specific embodiments and accompanying drawings.

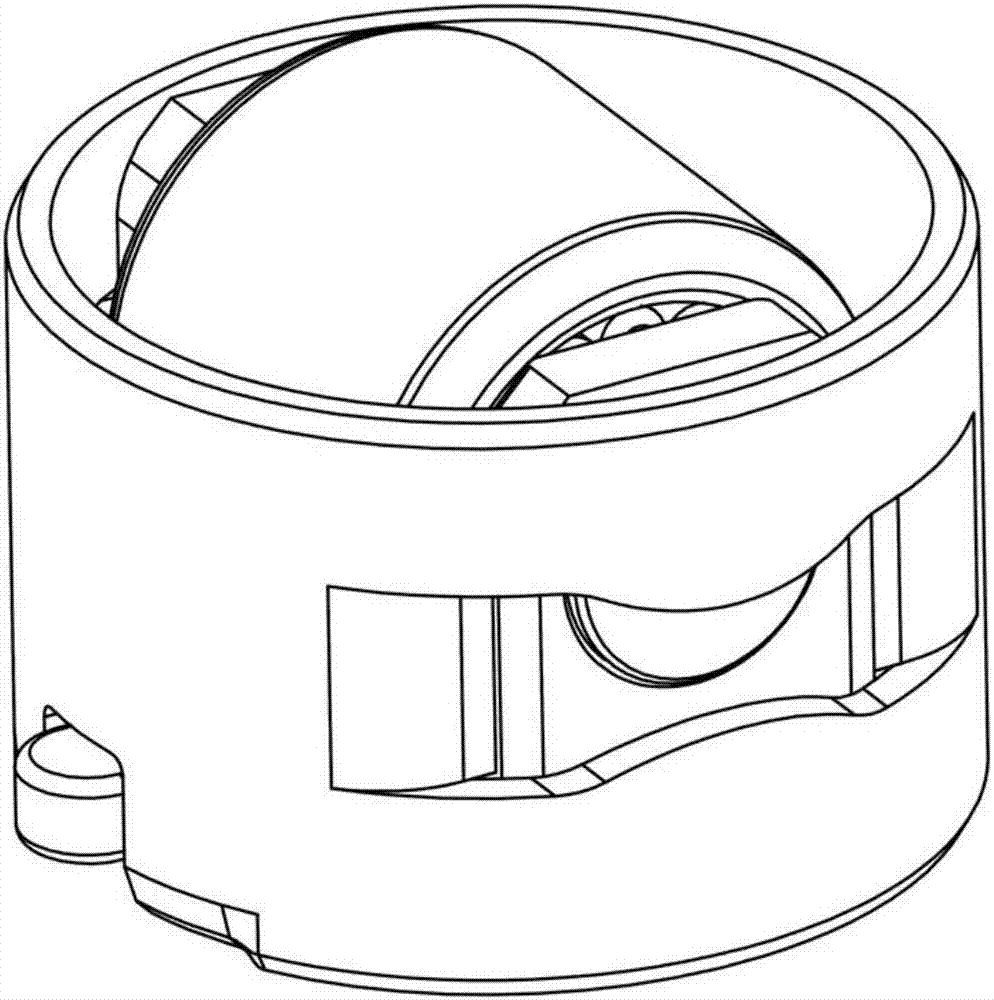

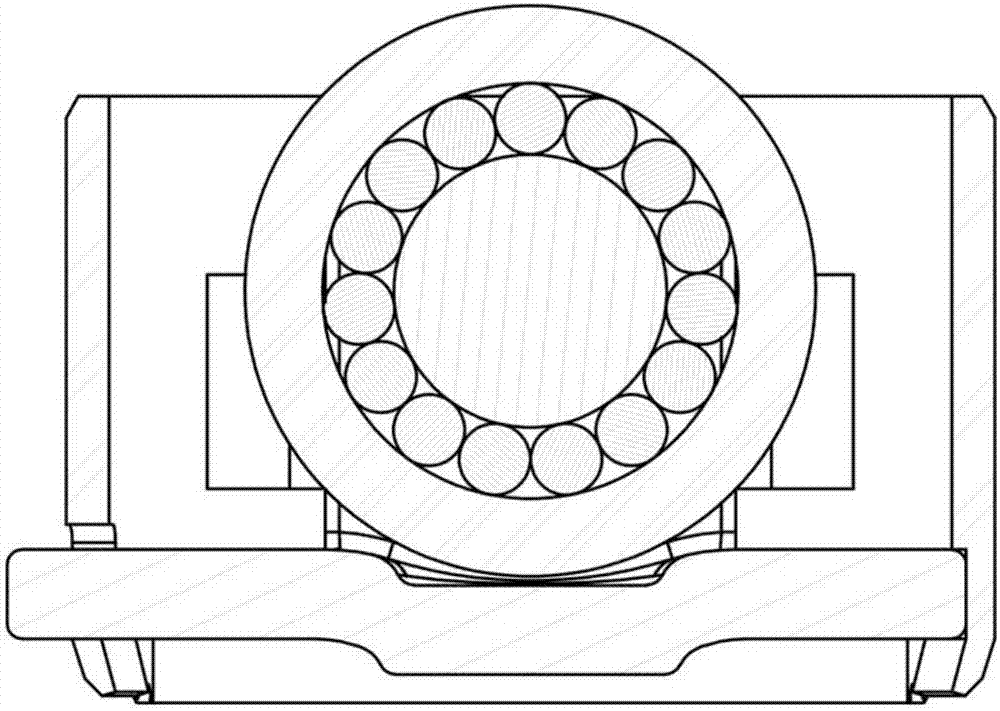

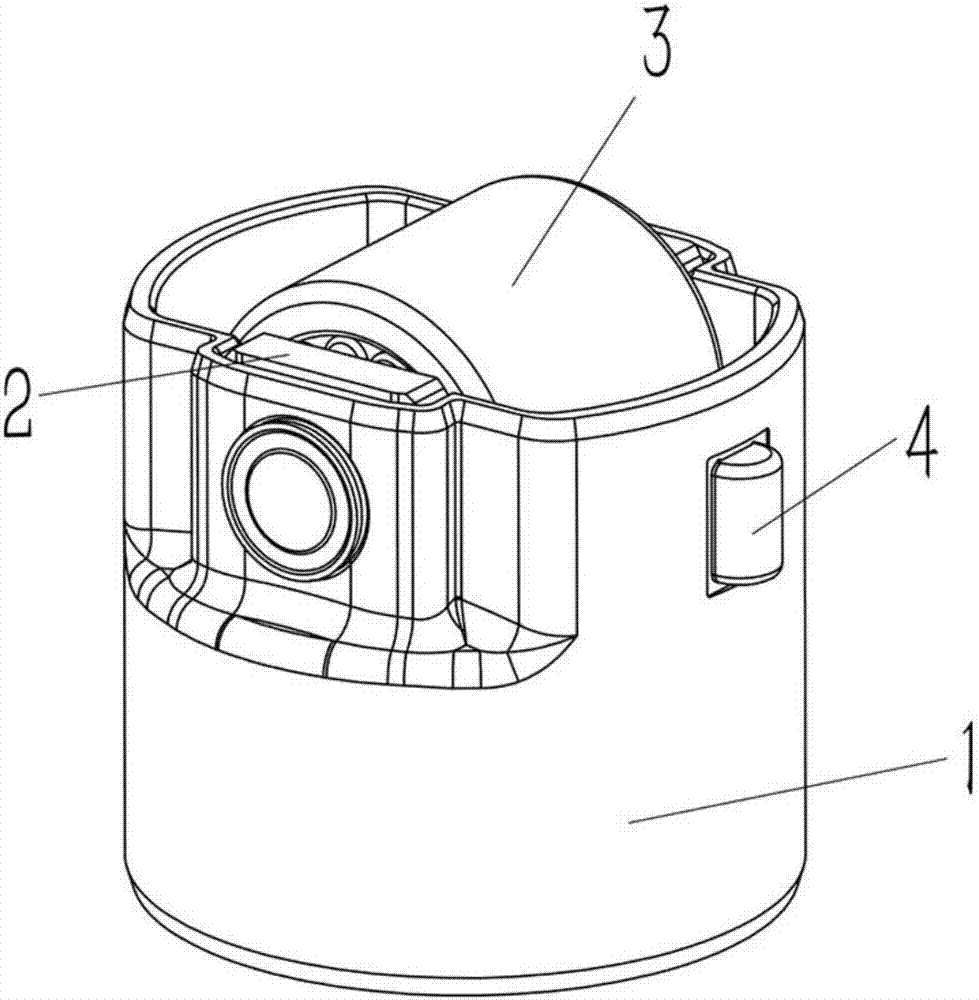

[0037] The implementation method is as follows: image 3 and Figure 4 As shown, a new type of high-pressure pump tappet is used in the engine fuel injection system. The roller tappet includes a guide sleeve 1, a U-shaped bracket 2, a pin roller set 3 and a positioning block 4, and the pin roller set 3 is installed On the U-shaped bracket 2, the U-shaped bracket 2 is installed in the guide sleeve 1, wherein: combined Figure 7 As shown, the U-shaped bracket 2 includes a base plate 2.1 and side plates 2.4 located on the left and right sides of the base plate 2.1, the symmetrical positions on the two side plates 2.4 are provided with shaft holes 2.3, and the front and rear sides 2.4 of the base plate 2.1 are transitions designed for equal strength curve. In the middle of the bottom plate 2.1 of the U-shaped bracket 2, a boss 2.5 protruding downward is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com