Vibration damper for ship shaft system and vibration damping method of vibration damper

A vibration damping device and shafting technology, which is applied to the transmission device, shock absorber, liquid shock absorber, etc. of synchronous propulsion components, can solve the problems of occupying limited space in the engine room, consuming vibration energy, and having no vibration damping effect. , to achieve the effects of easy replacement of parts, wide frequency band of vibration reduction, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in more detail below in conjunction with accompanying drawing example, further clarifies the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand the present invention Modifications of various equivalent forms of the invention all fall within the scope defined by the appended claims of the present application.

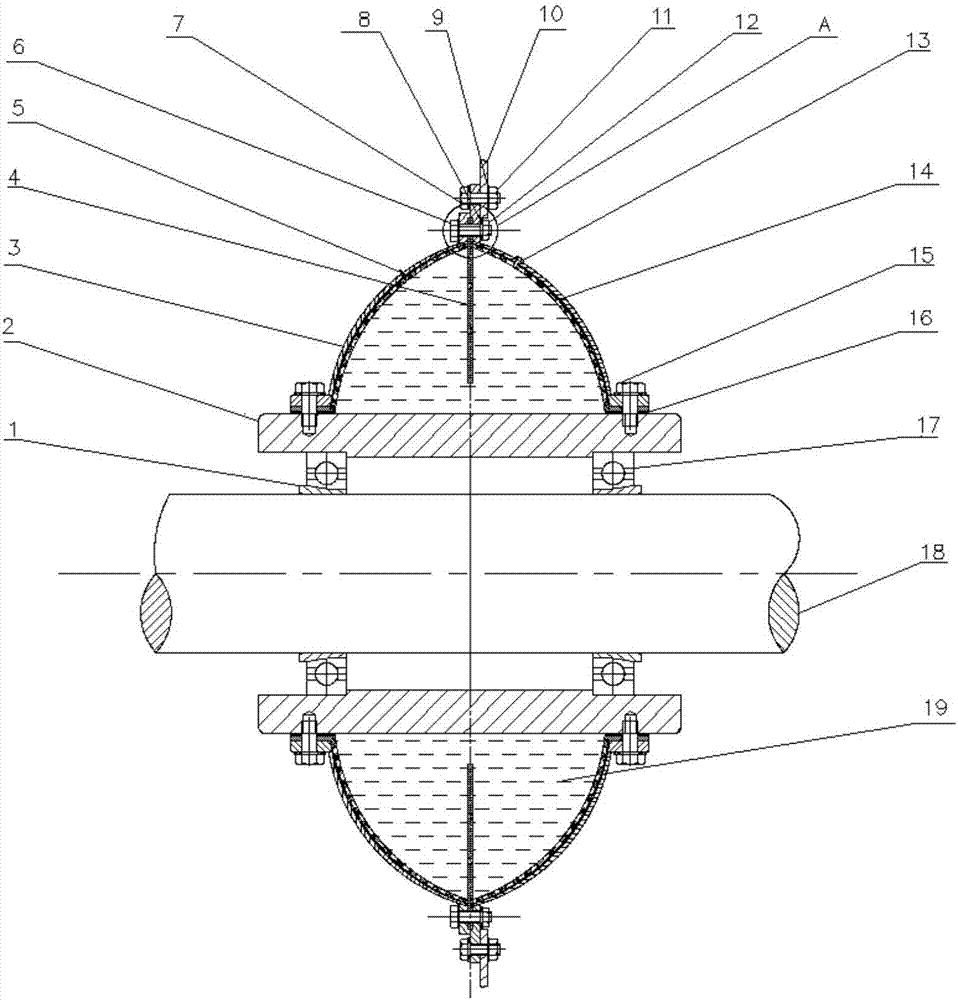

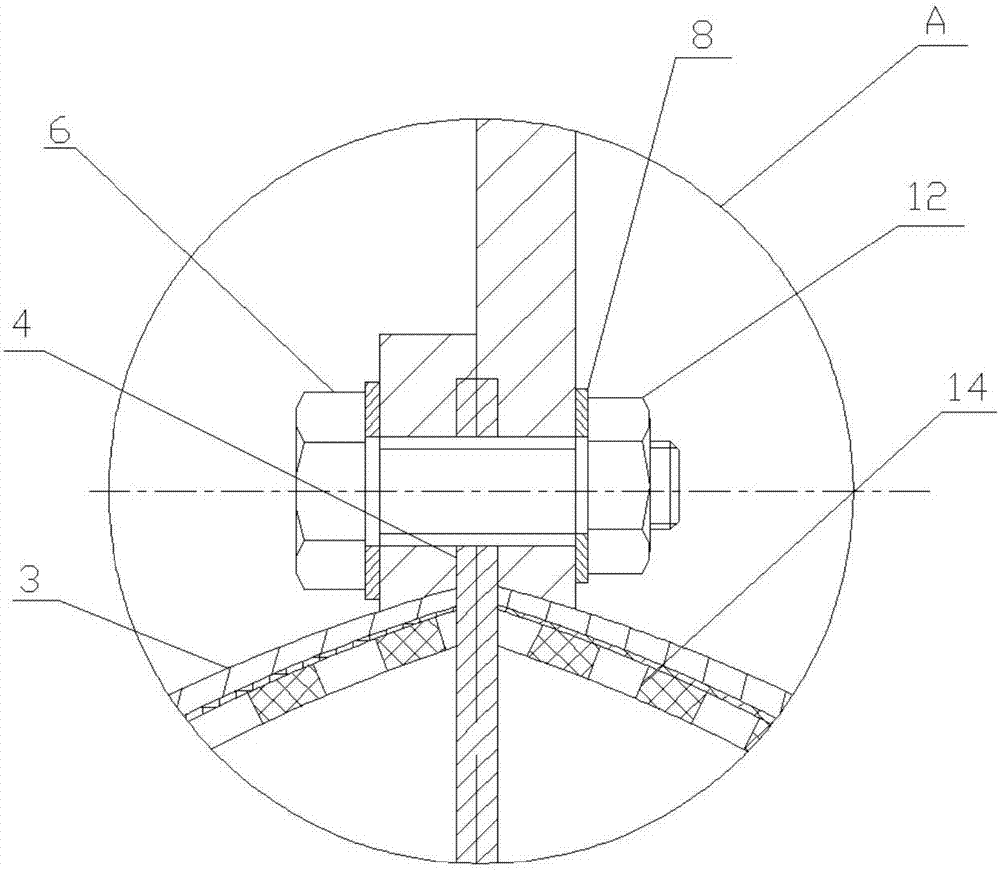

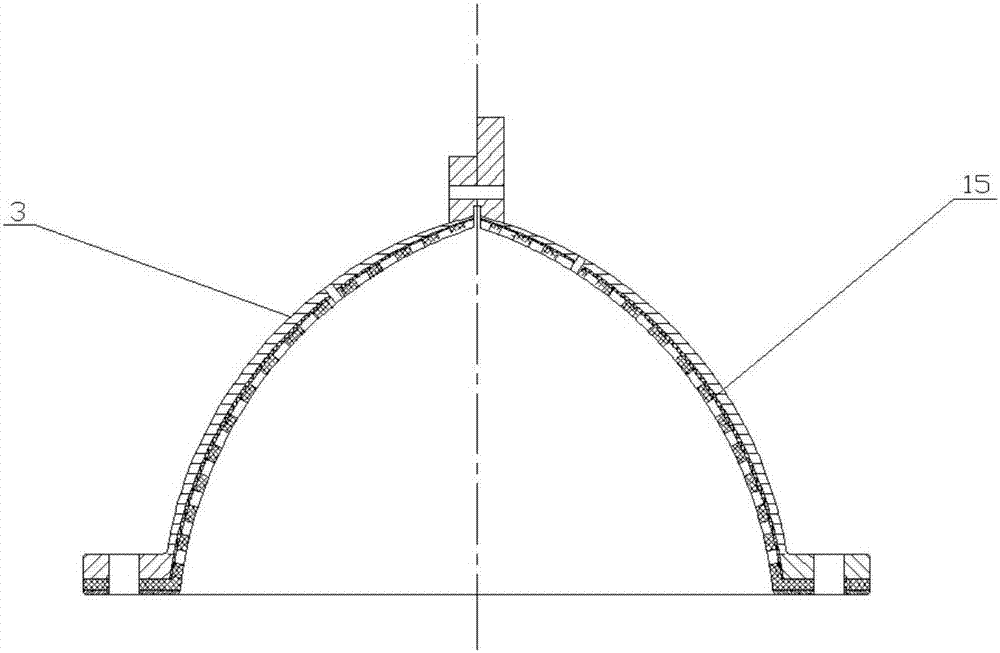

[0033] Such as Figure 1 to Figure 7 Shown: is a vibration damping device for ship shafting according to an embodiment of the present invention, including a shaft 18 and a bulkhead 10 supporting the shaft 18, and a pair of shaft sleeves with threads at the top are sleeved on the shaft 18 1. The bearing 17 whose inner mounting surface is a threaded taper is installed on the shaft sleeve 1, and the outer side of the bearing 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com