Gas water heater with microcirculation waterway

A gas-fired water heater and waterway technology, which is applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of unsatisfactory neutralization effect, long warm water period, and inability for users to use it, so as to improve the effective utilization of heat. , Improve the comfort of bathing, reduce the effect of ignition cold water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

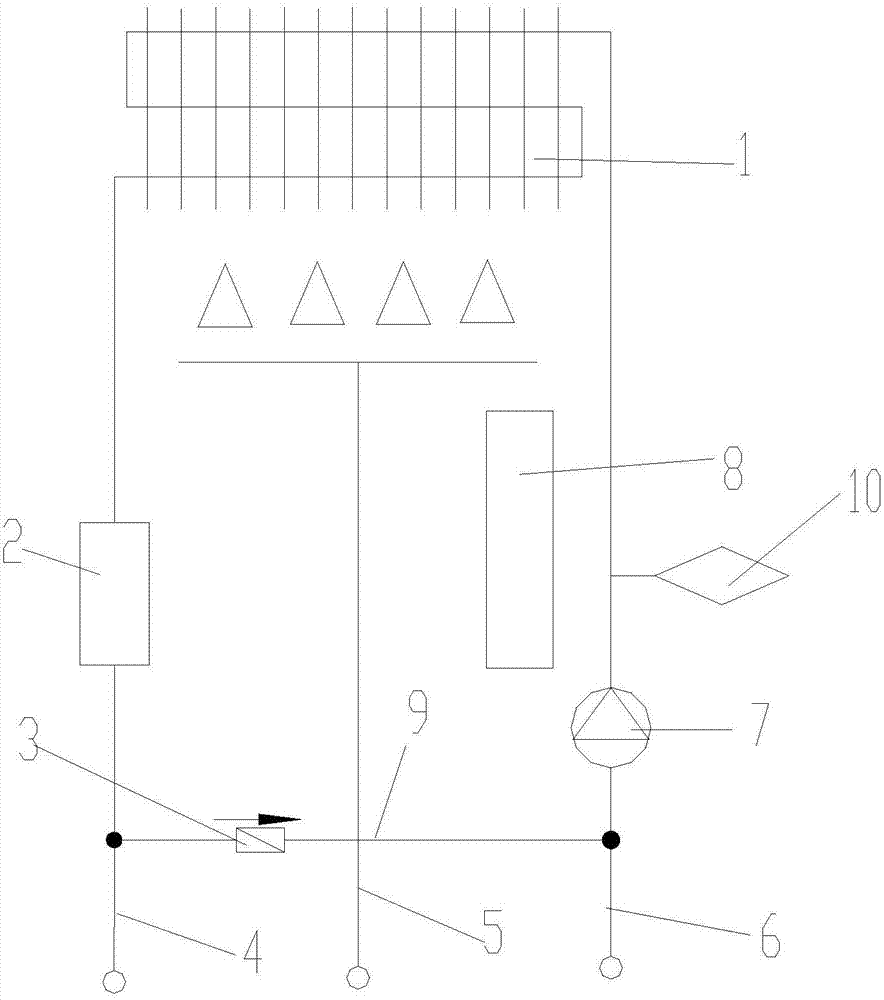

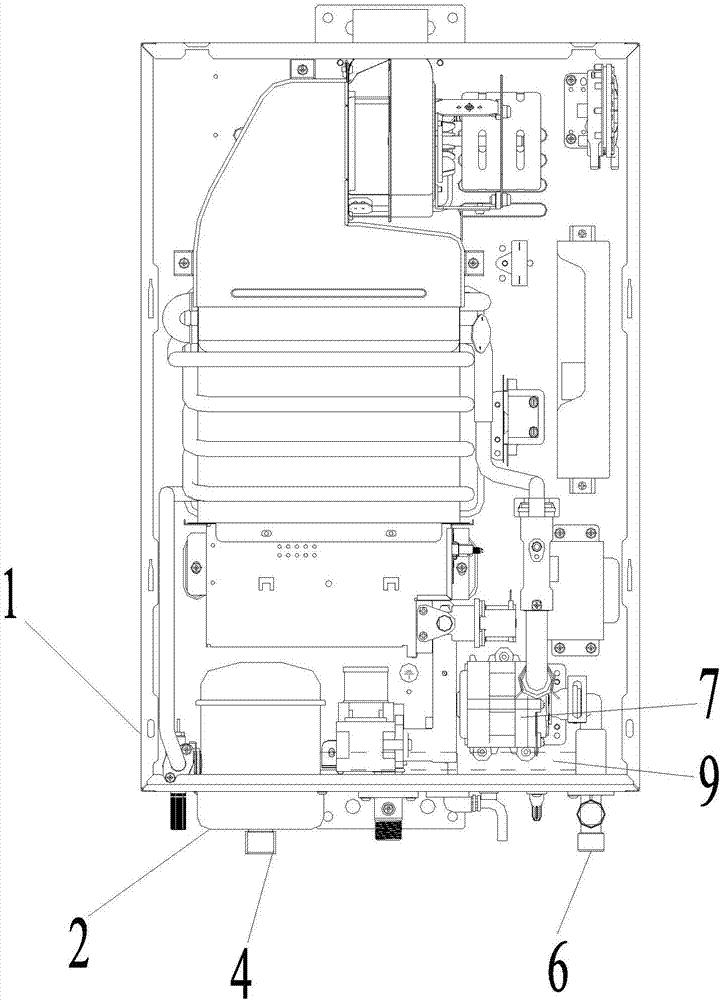

[0016] As an embodiment of the present invention, such as figure 1 , 2 A gas instant water heater with a microcirculation water circuit is shown, including a heat exchanger 1 and a constant temperature cabin 2, and a controller 8 arranged in the water heater, as well as a water inlet pipe 6 connected to the heat exchanger and a water inlet pipe connected to the constant temperature cabin. Outlet pipe 4, the thermostatic cabin is connected downstream of the water flow direction of the heat exchanger, and a microcirculation bypass channel 9 is also provided between the thermostatic cabin and the water inlet pipe, and a one-way channel is provided on the microcirculation bypass channel. Valve 3 and circulation pump 7, the control switch of described water pump is connected with described controller, is provided with temperature sensor on described constant temperature cabin, and described temperature sensor (not drawn in the figure) is connected with controller, in the constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com