A spreader reducer test system

A test system and reducer technology, applied in the testing of machine/structural components, instruments, and mechanical components, etc., can solve the problems of time consumption, inconvenient installation and disassembly, affecting equipment debugging, delivery schedule, etc., to improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

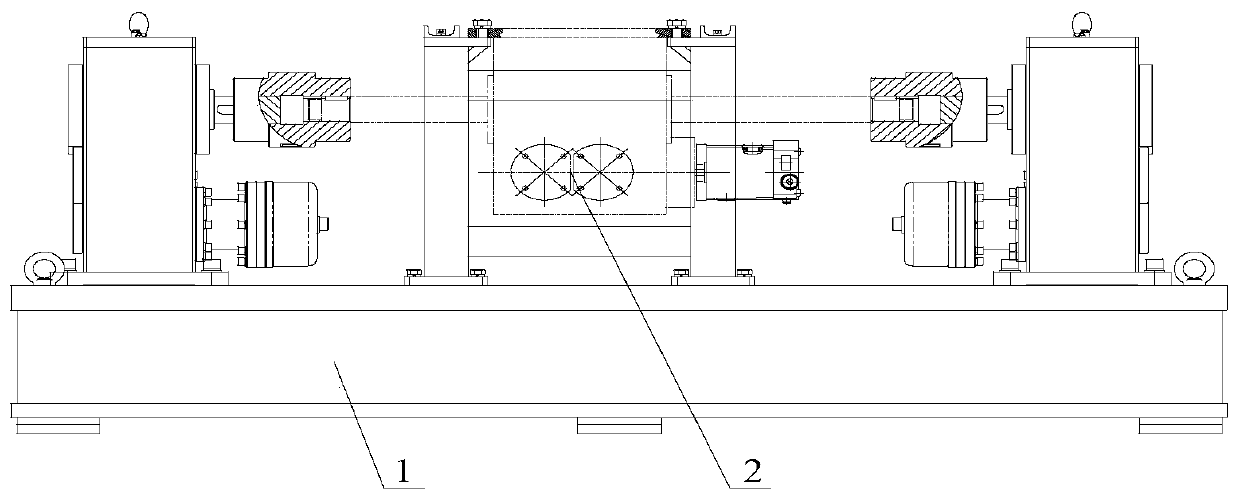

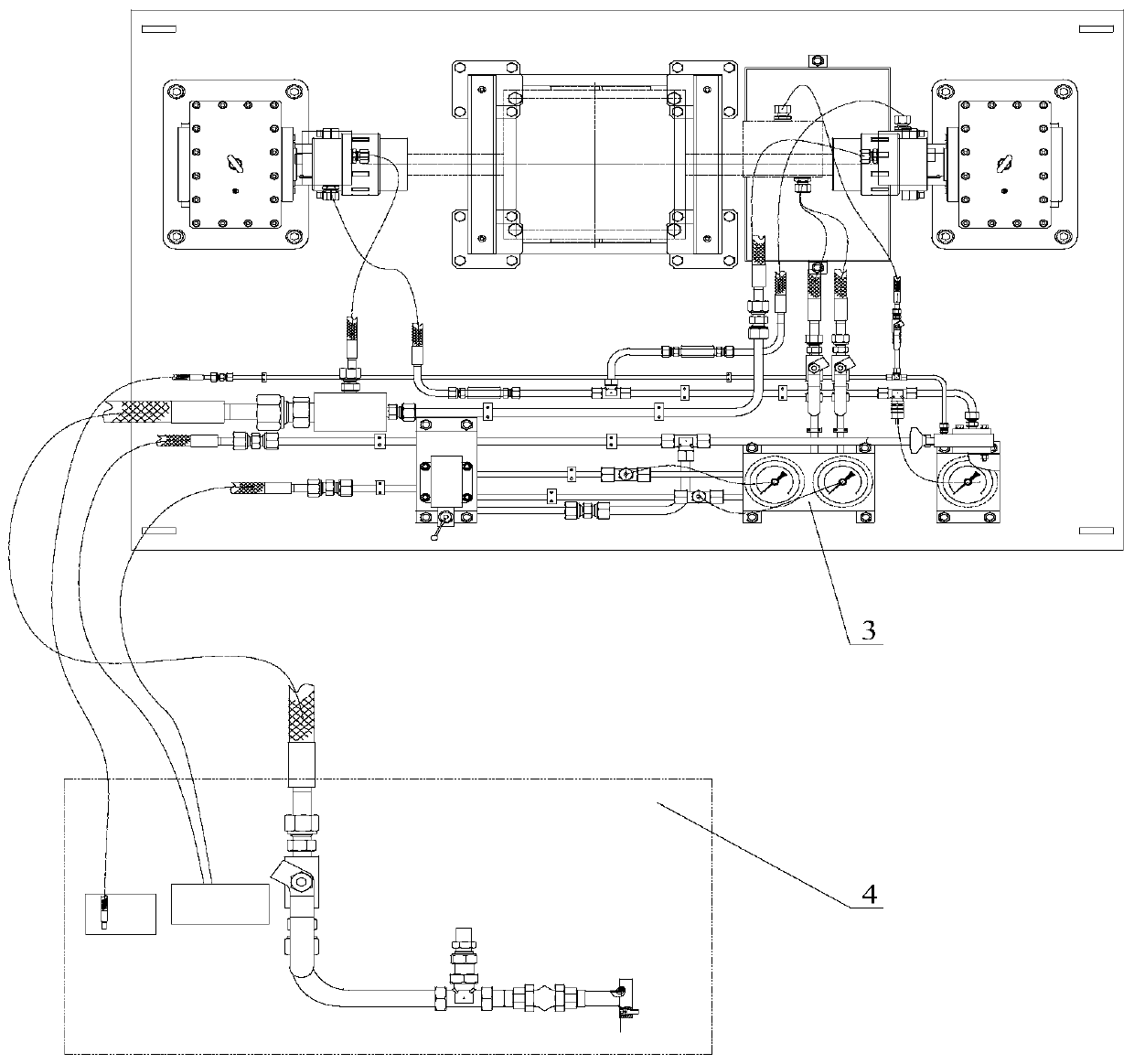

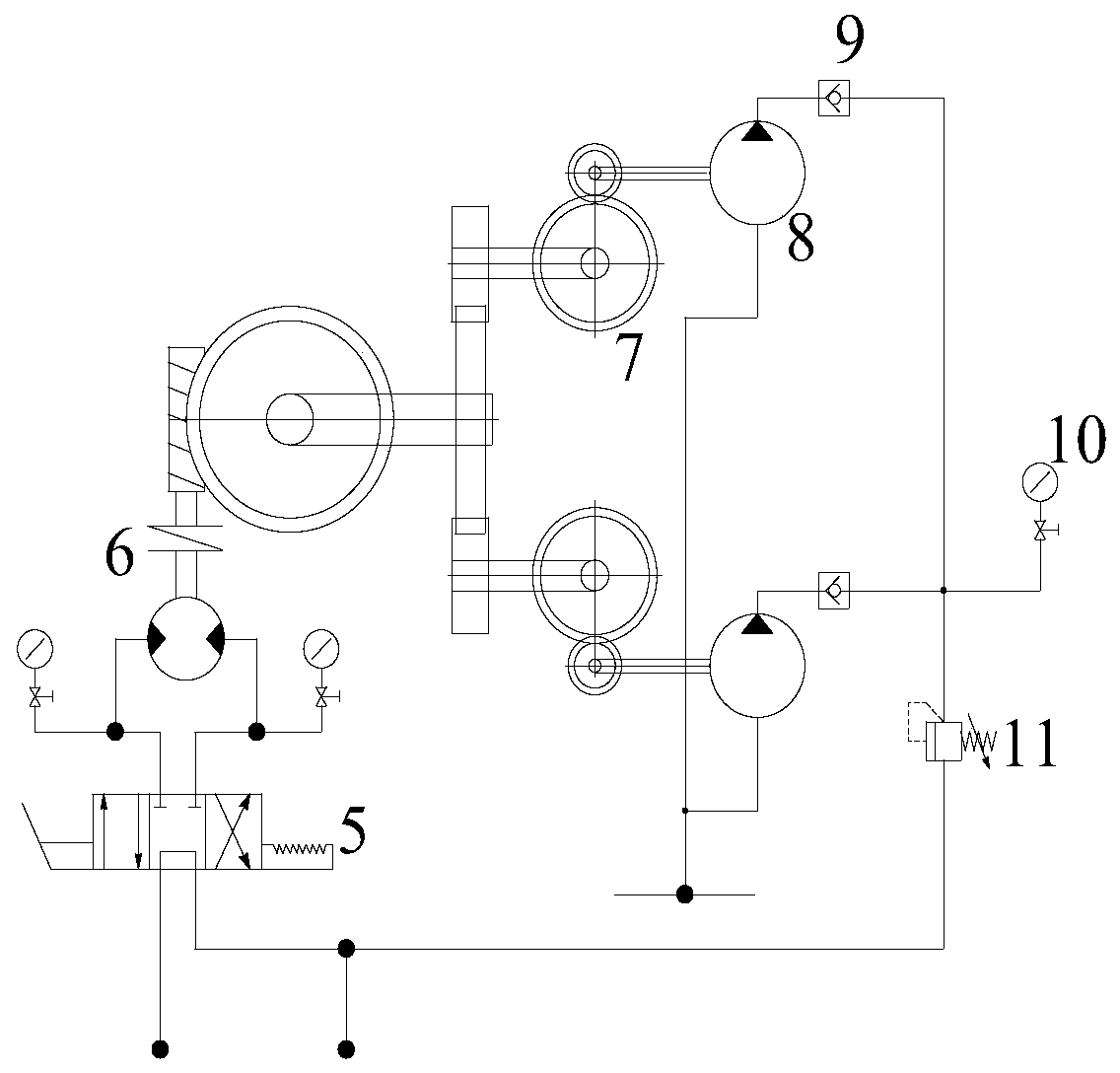

[0020] Such as Figure 1 to Figure 3 The shown test system for a spreader reducer includes a test bench 1, a spreader reducer 2, a hydraulic system 3, and a pump station 4; the spreader reducer 2 and hydraulic system 3 are installed on the test bench 1, and the hanger The reducer 2, the hydraulic system 3 and the hydraulic pipeline of the pump station 4 are connected to form a hydraulic circuit. The hydraulic system 3 has a motor 6 and an RK radial piston pump 8, and the hydraulic circuit controls the motor 6 and the RK radial piston pump 8 respectively. To work, the motor 6 drives the reducer 7 to be tested, and the reducer 7 acts on the RK radial piston pump 8 .

[0021] There are two RK radial piston pumps 8, two RK radial piston pumps 8 are connected to two pipelines, two reducers 7 act on the RK radial piston pumps 8 respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com