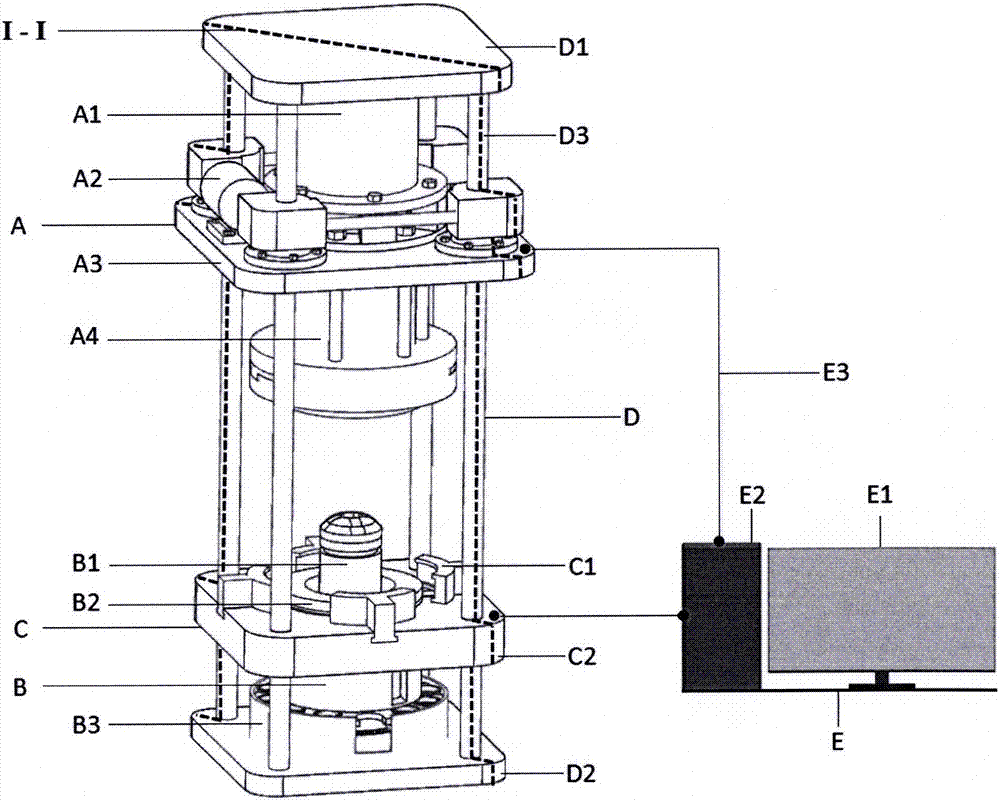

Novel pressure chamber for automatic output of fallen samples of rock mass in high-pressure environment

An automatic output, high-pressure environment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of rock test inconvenience, reduce discreteness, avoid accumulation, and optimize the test environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

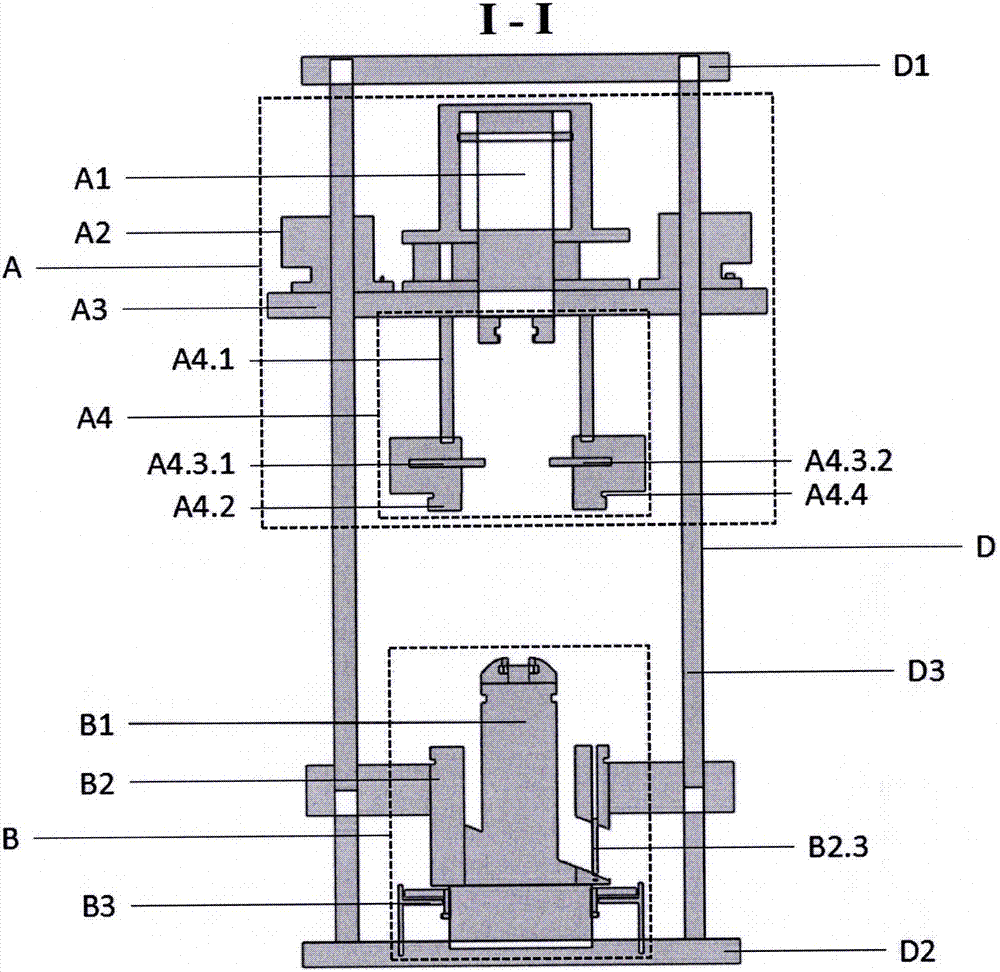

[0031] Below in conjunction with accompanying drawing, the course of work of the present invention is further described:

[0032] 1. Turn on the power and turn on E. High performance computing system.

[0033] 2. Start the E2. High-performance computer to check whether the status of each part of the pressure chamber is normal.

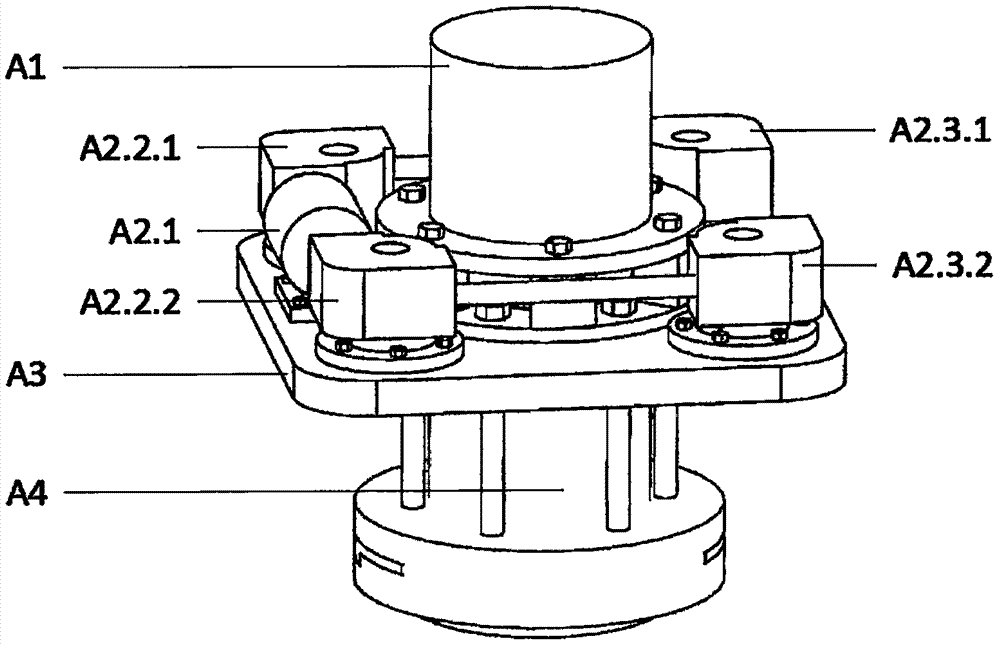

[0034] 3. After checking that the state of the pressure chamber is normal, raise the A. synchronous lifting system, place the rock block on the B1.1. clamping seat, and fix the bottom end of the rock block.

[0035] 4. After the rock block is fixed, E2. High-performance computer controls A. The synchronous lifting system descends along D3. The frame column until A4. The upper chamber of the pressure chamber is connected with the lower chamber of B2. The pressure chamber, and C1. The clamps are engaged Snap into A4.4. Bottom cover groove and B2.1. Barrel wall groove.

[0036] V. A1. The loading device moves down to the top of the rock block, ready to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com