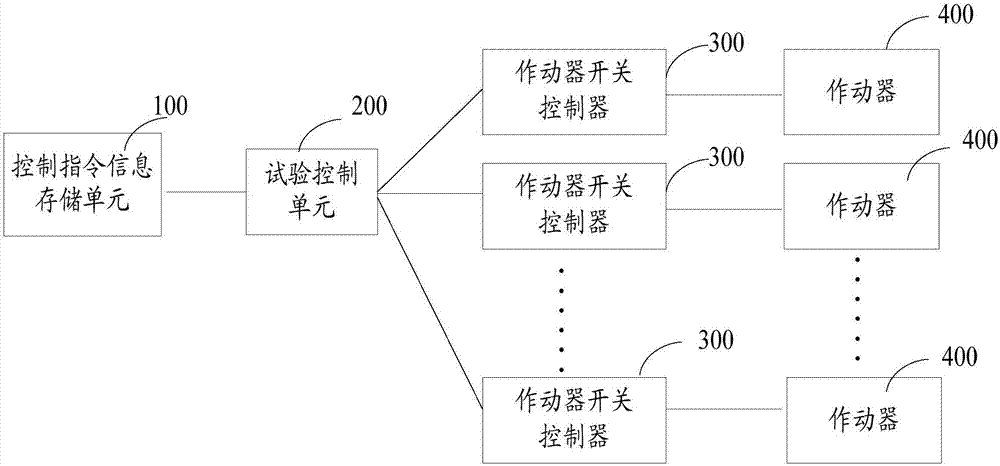

General fatigue test control system

A fatigue test and control system technology, applied in the field of fatigue test, can solve the problems of increasing the overall time, increasing the economic burden of test users, increasing the cost of test hardware investment, etc., to reduce the overall time, significant production practice significance, and reduce hardware economic investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

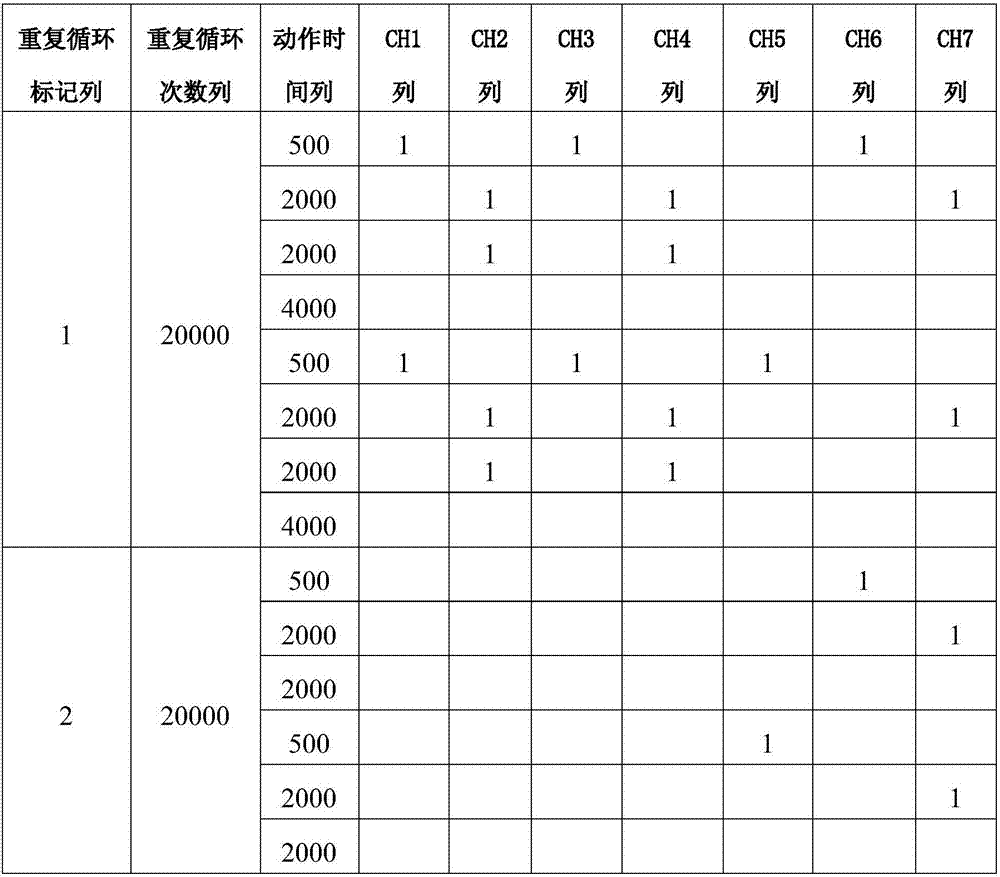

[0050] Apply the general fatigue test control system provided by the present invention to implement the fatigue test of a certain type of automobile with four doors and two covers, as follows:

[0051] Step 1: Analyze the specific actions included in the fatigue test: there are three types of actions, including opening and closing the front cover, opening and closing the rear cover, and opening and closing the doors on both sides. Among them, the action combination of opening and closing the front cover is to open the front cover lock → open → close the front cover lock → close; the combination of opening and closing actions of the rear cover is to open the rear cover lock → open → close the rear cover lock → close; The combination is to open the inner lock→pull the door→close the inner lock→close the door→open the outer lock→pull the door→close the outer lock→close the door.

[0052] Second step: through the general fatigue test control system provided by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com