Construction method of auxiliary jacking of large-span steel box girder suspension cable tower

A technology for sling tower and jacking construction, which is applied in the directions of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large span, fulcrum reaction force control, and temporary piers in the middle of the span that cannot be spanned, and achieves convenient construction. , Simple steps, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings.

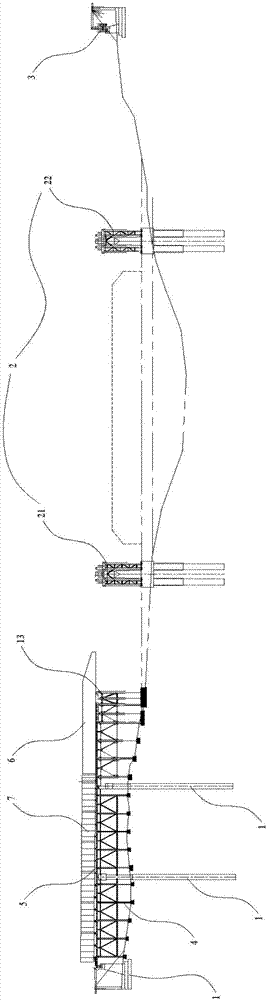

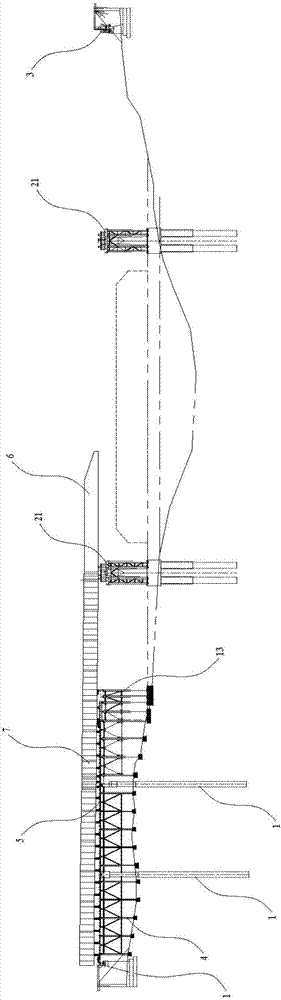

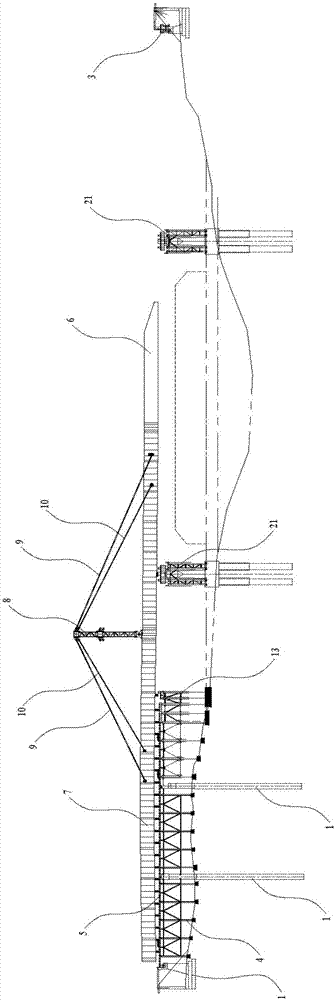

[0034] refer to figure 1 As shown, one embodiment of the present invention is a large-span steel box girder sling tower assisted jacking construction method, the construction method includes the following steps:

[0035] Step S1, lay out the assembly platform pier 1, the middle pier 2 and the end pier 3 in the construction area; and assemble the assembly support 4 between the assembly platform pier 1; then arrange the slideway beam 5 on the assembly support 4, the aforementioned assembly support 4 That is, as the assembly platform of the steel box girder 7, the steel box girder 7 extending to the middle pier 2 and the end pier 3 are all assembled on this platform, that is, a part is assembled and a part is pushed forward;

[0036] Step S2, as mentioned above, assemble the guide beam 6 on the assembly bracket 4, and continue to assemble the first section of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com