Coiled tubing dragging sand blasting perforation and annulus sand filling staged fracturing method

A technology of sand blasting, perforating, and staged fracturing, which is used in earth-moving drilling, wellbore/well components, and production fluids. The effect of good integrity and lower construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

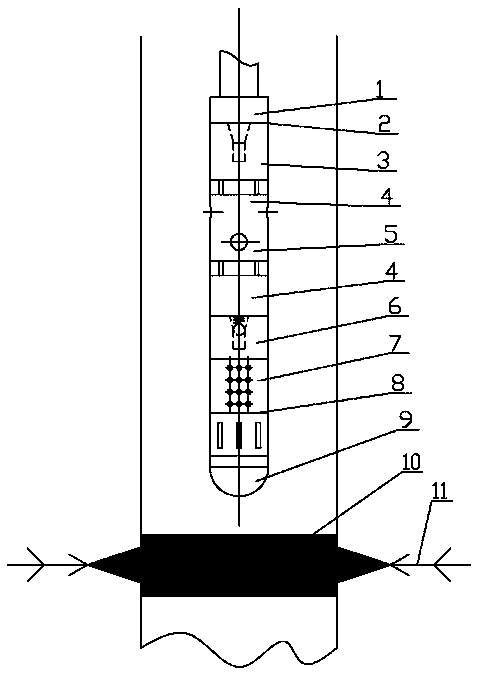

[0021] Embodiment 1: as attached figure 1 As shown, the method of coiled tubing dragging sandblasting perforation and annulus sand filling staged fracturing is carried out as follows: the first step is to drill the well to the position of the fractured layer; the second step is to place the coiled tubing 1 , outer slip connector 2, hydraulic hand release tool 3, trough centralizer 4, sand blaster 5, trough centralizer 4, ball stop reverse circulation valve 6, screen pipe 7, collar locator 8, guide shoe 9. Fixedly connect together from top to bottom to form a fracturing string; the third step is to lower the fracturing string to the designed depth in the well, and position the sand blaster 5 to the formation perforation position through the collar positioner 8; In four steps, the sand-carrying fluid is injected from the coiled tubing 1, and the sand-carrying fluid passes through the fracturing string. Due to the blocking effect of the ball stop reverse circulation valve 6, the ...

Embodiment 2

[0029] Embodiment 2: as attached figure 1 As shown, the method of coiled tubing dragging sandblasting perforation and annulus sand filling staged fracturing is carried out as follows: the first step is to drill the well to the position of the fractured layer; the second step is to place the coiled tubing 1 , outer slip connector 2, hydraulic hand release tool 3, trough centralizer 4, sand blaster 5, trough centralizer 4, ball stop reverse circulation valve 6, screen pipe 7, collar locator 8, guide shoe 9. Fixedly connect together from top to bottom to form a fracturing string; the third step is to lower the fracturing string to the designed depth in the well, and position the sand blaster 5 to the formation perforation position through the collar positioner 8; In four steps, the sand-carrying fluid is injected from the coiled tubing 1, and the sand-carrying fluid passes through the fracturing string. Due to the blocking effect of the ball stop reverse circulation valve 6, the ...

Embodiment 3

[0030] Embodiment 3: As an optimization of the above embodiment, in the fourth step, the displacement of the sand-carrying fluid through the perforation is 0.5m 3 / min to 0.8 m 3 / min, the amount of sand used for perforation is 0.8m 3 to 1m 3 , in the sand-carrying fluid, the volume percentage of sand is 70% to 75%; or / and, in the fourth step, the pressure of injecting the sand-carrying fluid from the coiled tubing 1 is 20MPa to 70MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com