Constant velocity universal joint driving shaft assembly

A constant velocity universal joint and universal joint technology, applied in the direction of coupling, elastic coupling, vibration suppression adjustment, etc., can solve the problem of poor controllability of rotation angle, high machining accuracy of ball cage type universal joint, contact stress Large and other problems, to achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

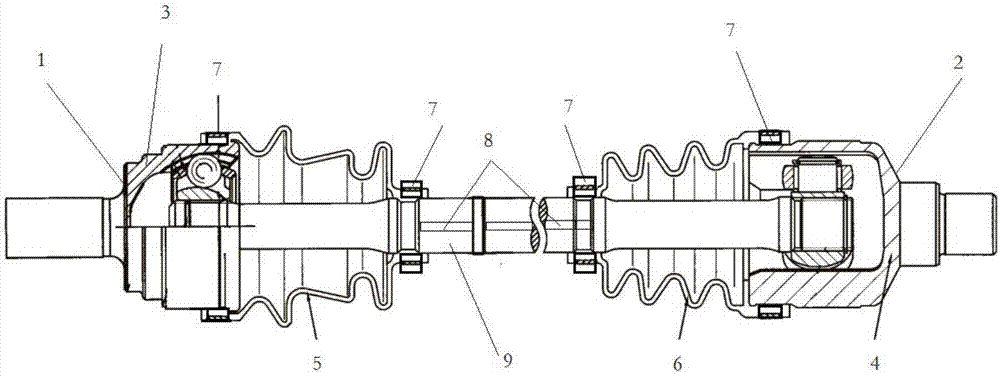

[0011] Such as figure 1 As shown, a constant velocity universal joint drive shaft assembly includes tripod joint 2, ball cage joint 1, intermediate shaft 9, weight block 7 and shock absorbing groove 8, tripod joint The universal joint 2 includes the three-ball universal joint shell 4 and the three-ball pin dust cover 6, the ball cage universal joint 1 includes the ball cage universal joint shell 3 and the ball cage dust cover 5, and the three-ball pin One end of the dust cover 6 and the ball cage dust cover 5 are respectively lapped on the three-ball joint housing 4 and the ball cage joint housing 3, and the other ends are respectively fixed on the intermediate shaft 9, and the three-ball joint A weighted block 7 is provided at the joint between the joint housing 4 and the three-ball pin dust cover 6, and a weighted block 7 is provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com