Detection device fixing device and method for detecting position precision of rod clamping groove

A technology for fixing devices and testing instruments, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of high replacement rate of dial gauge testing equipment, affecting the detection efficiency of clamping rod slots, and affecting the detection accuracy of dial gauges, etc. Achieve the effect of reducing loss, reducing detection cost and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

[0027] The embodiment of detection instrument fixing device:

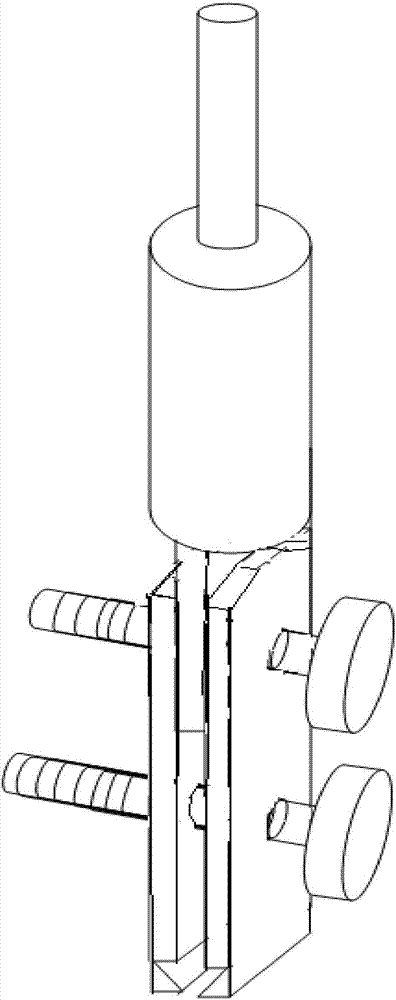

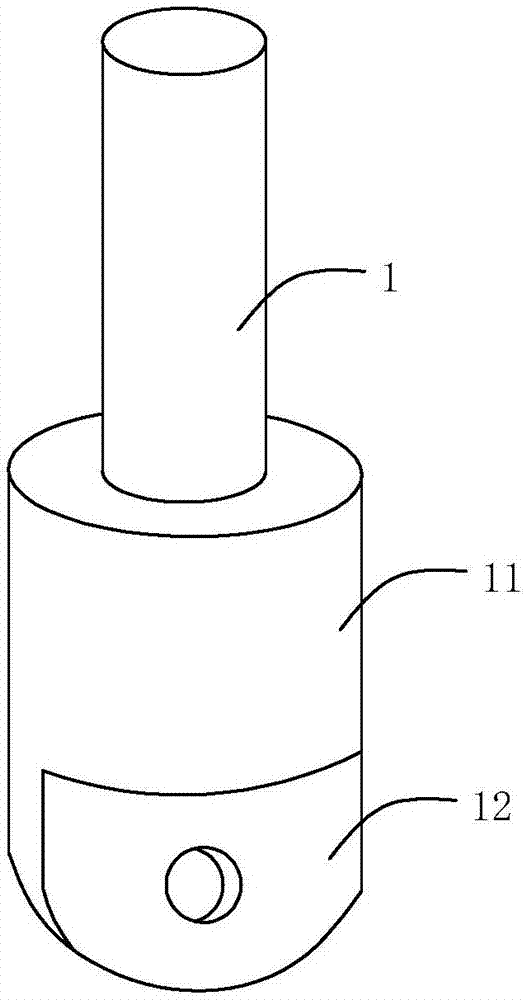

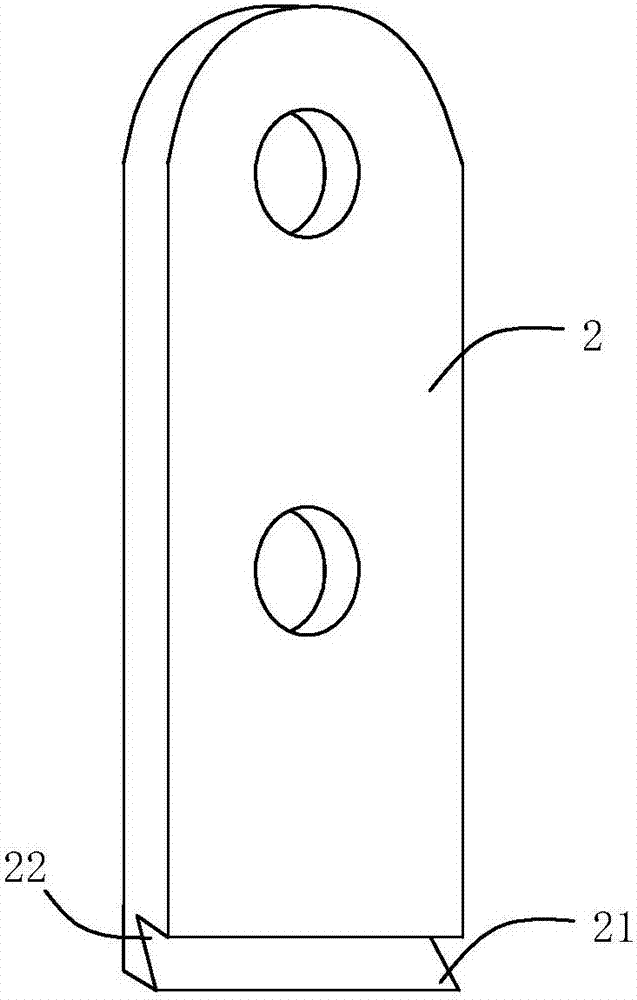

[0028] refer to Figure 1 to Figure 4 , the present invention provides a fixing device for testing instruments, comprising a nail rod 1 for being installed on the drilling machine main shaft 7 and a clamping device for being arranged on the dial indicator 4; the diameter of the nail rod 1 is 3.175mm, and the length is 16.8mm. The nail bar 1 is provided with a cylindrical transition section 11, the diameter of the cylindrical transition section 11 is 7.95mm, and the length is 10.2mm. The bottom of the cylindrical transition section 11 is provided with a connection end 12 for connecting with the clamping device. The diameter of the connection end 12 is the same as the diameter of the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com