Blade clamping base and blade clamping fixture

A blade and clamping technology, which is applied in the field of cutting processing, can solve the problems of lower product qualification rate, long production cycle, and incompatibility, and achieve the effects of improving product qualification rate, reducing processing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

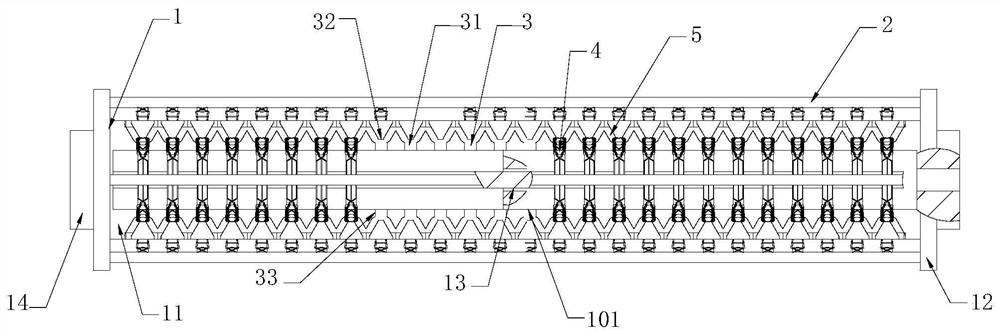

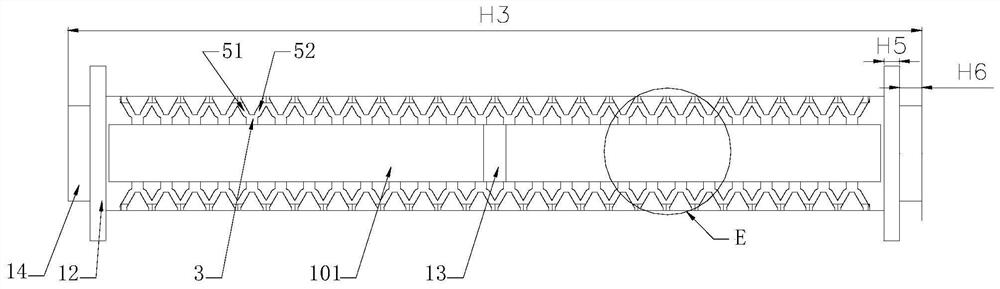

[0038]Such asFigures 1 to 7 As shown, the blade mounting base of the present embodiment includes a base 1 and a plurality of pressure rods 2, and the base 1 includes a square column 11, and each side of the square column 11 is provided with a support end seat 12, a square column 11. A set of positioning grooves 3 is provided, and each set of positioning grooves 3 includes a plurality of positioning grooves 3 arranged at intervals along the length direction of the square column 11, and the positioning groove 3 is used to mount the blade 4, and each set of positioning grooves 3 corresponds to a pressure rod 2, press The rod 2 is used to press the blade 4 in the positioning groove 3, and both ends of the pressure rod 2 are respectively provided on the support end seat 12 on both ends. The blade 4 is a non-porous installed cut cut slot blade.

[0039]The square column 11 of the present embodiment is square in a square in cross section. On the other hand, the square column 11 has four sides...

Embodiment 2

[0049]Such asFigure 8 As shown, the blade assembly clamp of the present embodiment includes a housing 6 and the blade mount base of the above-described Embodiment, and the base is provided on the strip rod 6, and both ends of the binder 6 from the base 1 support end. The seat 12 extends, and the binder 6 exits the dial 61 of the drive rod 6 rotating.

[0050]In this embodiment, the support end seat 12 is provided with a central bore, and the stripper 6 penetrates the center hole to achieve the blade mounting base to satisfy the blade coating process. The strip rod 6 rotates with the base 1 to ensure that the blades 4 are coated.

[0051]In the present embodiment, the strip rod 6 is a standard strip of the apparatus, and the outer diameter D1 of the strip rod 6 and the center hole in the support end seat 12, D1 <D1, 0.1 mm ≤ D1-D1 ≤ 1mm, preferably D1-D1. = 0.4 mm. The binder 6 height h4 = 315 mm, the base 1 height H3 and the binder 6 height H4 satisfy the relationship H3 <H4, 20 mm ≤ h4-H...

Embodiment 3

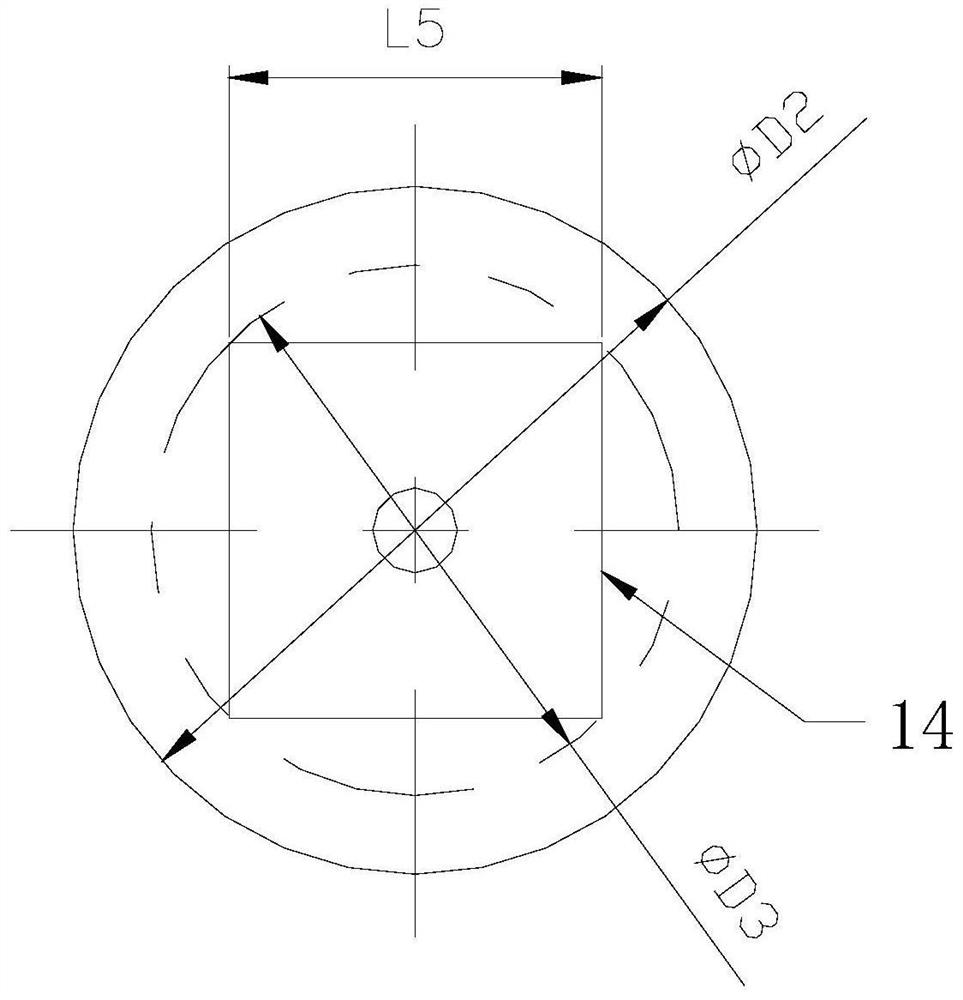

[0053]Such asFigure 9 to 11 As shown, the blade assembly clamp, including the tray frame 7 and the blade mount base of the above-described embodiment, and two support end seat 12 of each end, two of the pallets 14, the pallet frame 7 opposite A plurality of square grooves 71 are respectively provided on the border, and the square recess 71 on both frames corresponds to the two square grooves 71 corresponding to the two frames, and the two square recess 71 constitute a set of square grooves 71, the blade clamp A plurality of seats are arranged, and each blade mount base is engaged in each parallelete groove 71 through a square boss 14 at both ends.

[0054]When the blade mount base should be used in combination with the tray frame 7 during the cleaning process, the square groove 71 prevents the blade assembly base position from being shifted, and placed the tray frame 7 and the blade clip base on the cleaning. On the device, the blade cleaning process can be satisfied.

[0055]In this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com