Inspection apparatus

A technology of inspection device and mobile device, which is applied to measurement devices, transportation and packaging, and exploration of nuclear radiation, etc., can solve the problems of baffle structure, complicated control, large baffle size, and speed reduction, and shorten the inspection time. , The effect of preventing radiation leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0063]

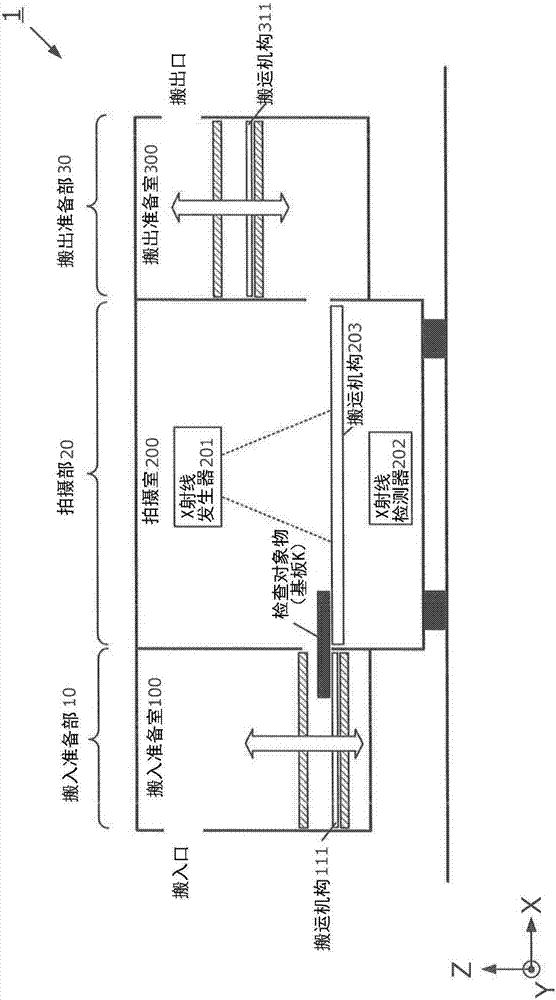

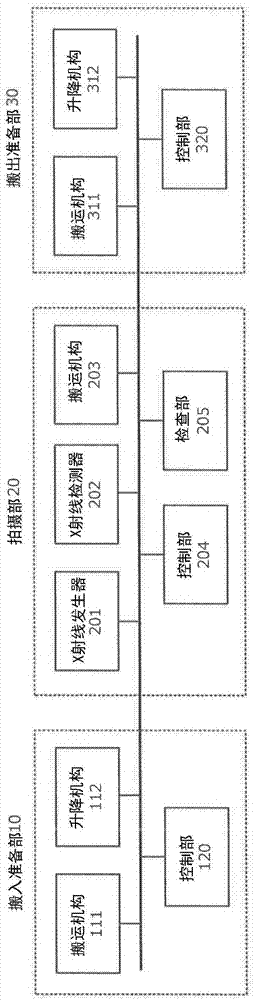

[0064] First, refer to figure 1 and figure 2 , the configuration of the X-ray inspection apparatus according to this embodiment will be described. figure 1 is a cross-sectional view schematically showing the X-ray inspection apparatus 1 of the present embodiment, figure 2 It is a block diagram showing the configuration and functions of the X-ray inspection apparatus 1 . Such as figure 1 and figure 2 As shown, the X-ray inspection apparatus 1 has a carry-in preparation unit 10 , an imaging unit 20 , and a carry-out preparation unit 30 .

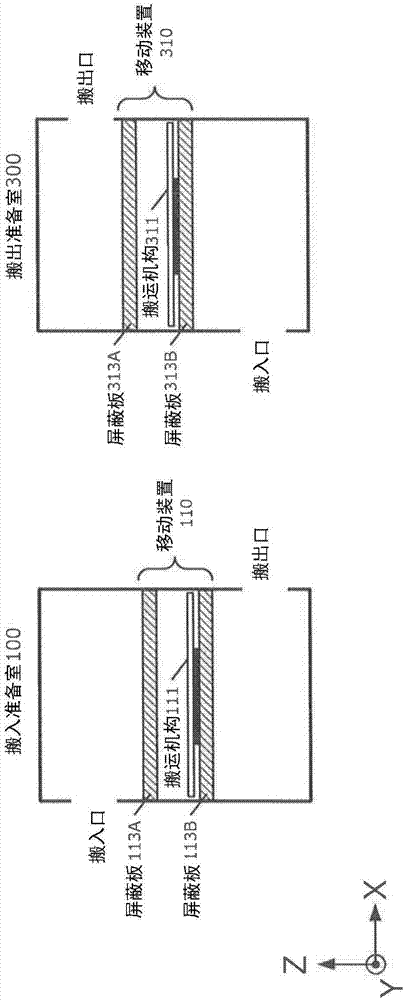

[0065] in addition, figure 1 is a diagram schematically showing the flow of the substrate during the inspection, refer to the following image 3 A device for shielding X-rays will be described.

[0066] Such as figure 1 As shown, the main body of the X-ray inspection apparatus 1 is provided with an imaging unit 20 for performing X-ray imaging, and a loading preparation unit for loading the substrate K of the inspection ob...

no. 2 approach

[0122] In the first embodiment, the conveyance mechanism 203 is fully covered in the imaging chamber 200, and the substrate placed on the conveyance mechanism 203 moves. In contrast, the second embodiment is an embodiment in which the substrate is moved by the moving transport mechanism 203 itself. Figure 8 It is a sectional view schematically showing the X-ray inspection apparatus 1 of the second embodiment.

[0123] As shown in the figure, in this embodiment, the transport mechanism 203 can move along the X-axis direction in the figure.

[0124] In the second embodiment, the transport mechanism 203 is moved to a position capable of receiving the substrate before the process of step S21 is started. In addition, before the process of step S25 is started, the transport mechanism 203 is moved to a position where the substrate can be discharged. In addition, after step S27 ends, while the conveyance mechanism 203 is moved to the position which can receive a board|substrate, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com