Safe separation mechanism used for missile electrical connecting piece

A technology for electrical connectors and safety, which is applied in the direction of electrical components, parts of connecting devices, connections, etc., can solve the problems of large occupied space, high manufacturing cost, inconvenient operation, etc., and achieve low manufacturing cost, easy operation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

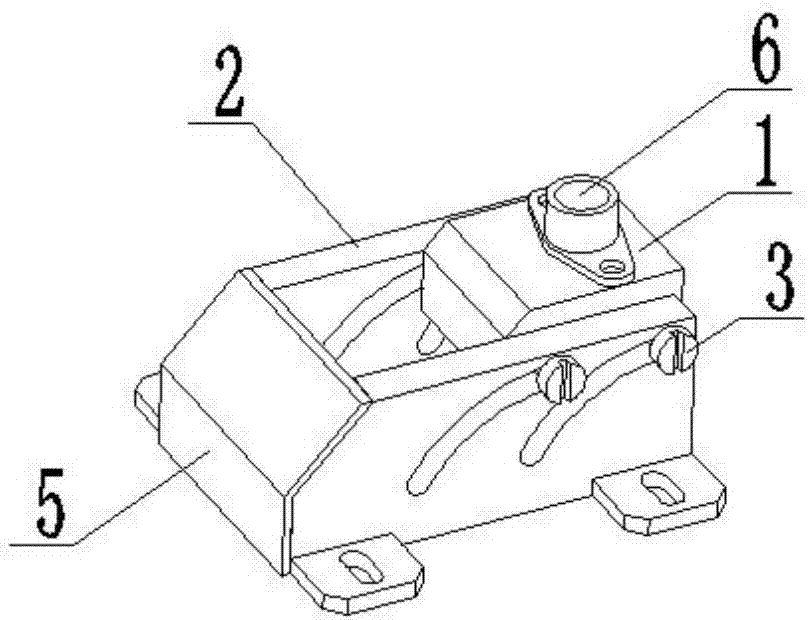

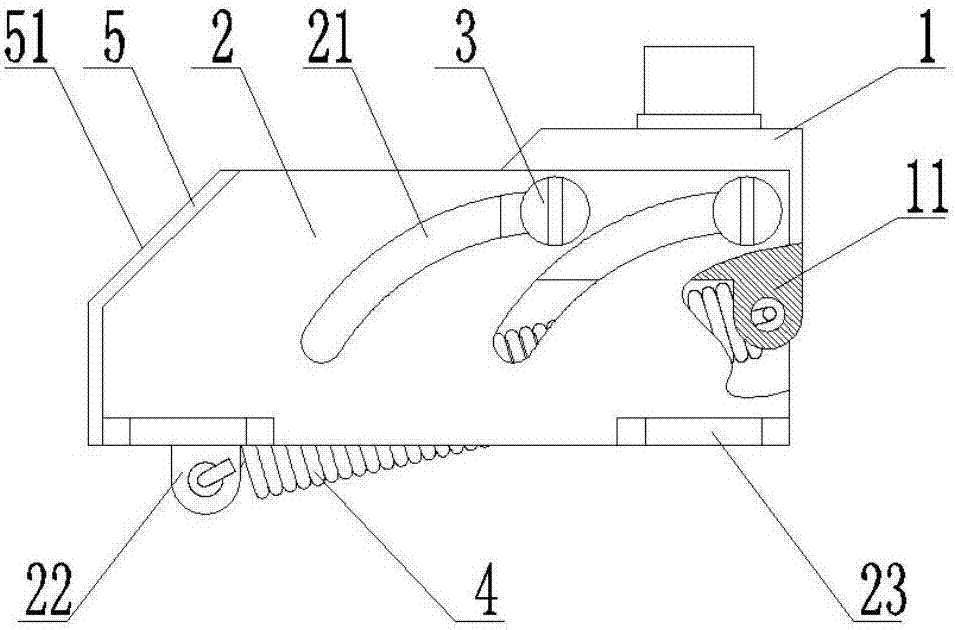

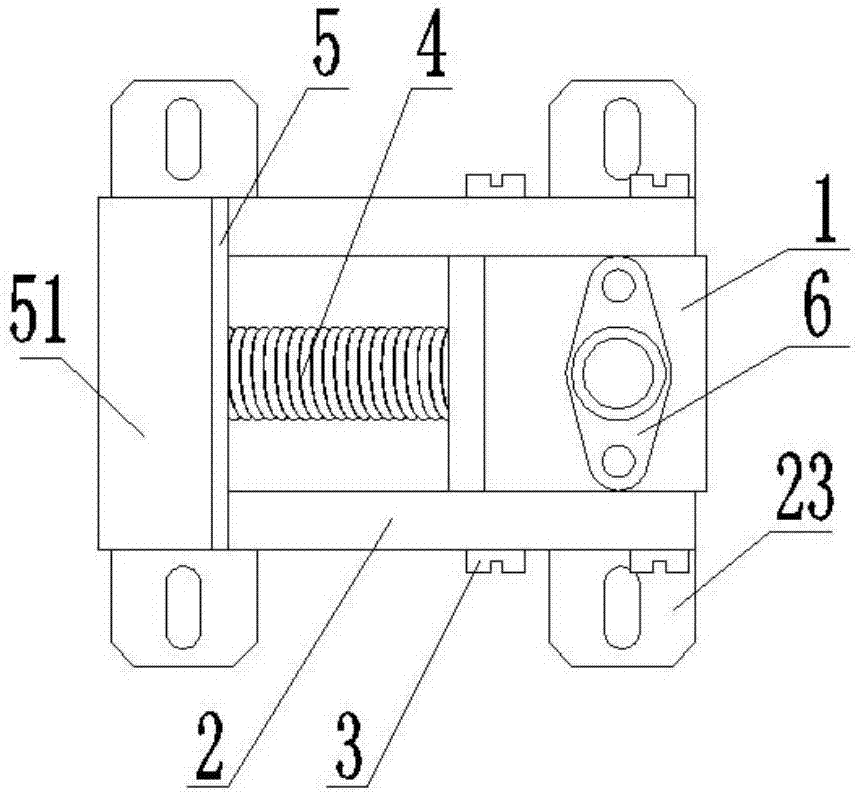

[0020] The present invention provides a safety disengagement mechanism for missile electrical connectors, such as figure 1 , figure 2 , image 3 As shown, it includes a mounting base 1 and a guide plate 2. A separation track 21 is provided on the guide plate 2. Fasteners 3 are provided on both sides of the mounting base 1. The fastener 3 is slidably connected to the separation track 21. Using the technical solution of the present invention, the plug or socket in the electrical connector can be installed on the mounting base 1 using fasteners such as bolts, and is integrated with the mounting base 1. During the storage or transportation of ballistic missiles, the electrical connector remains reliable. ground connection, and when the ballistic missile is launched, the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com