Filter

A filter, body technology, applied to the filter. It can solve the problems of inability to clean the impurities of the filter screen, affecting the filtering work of the filter screen, and reducing the working efficiency of the filter, so as to achieve the effect of simple structure, reducing impurities and high cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

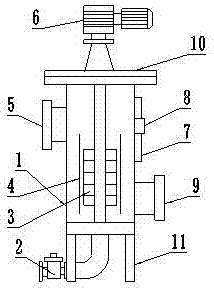

[0009] Such as figure 1 As shown, a filter is composed of a body 1, a sewage valve 2, a filter screen 3, a scraper 4, an inlet 5, an electric reducer 6, a pressure sensor 7, a signal converter 8, an outlet 9, a sealing top cover 10 and The bracket 11 consists of three uniform bottom edges of the connector body 1, the bottom center of the drain valve 2 connector body 1, the filter screen 3 inner center position of the connector body 1, and the two sides of the filter screen 3 are respectively provided with Scraper 4, inlet 5, upper left side of connector body 1, outlet 9, lower right side of connector body 1, signal converter 8, upper right side of connector body 1, pressure sensor 7 next to signal sensor 8, and sealed top cover 10 through The nut is connected to the top of the body 1, and the electric speed reducer 6 is connected to the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com