Preparation method of near-infrared light codoped silver sulfide nano-luminescence material

A nano-luminescent material and near-infrared light technology, which is applied in the field of nano-materials, can solve problems such as unfavorable large-scale industrial production, organic solvents are harmful to health, and complex production processes, and achieve good application prospects, easy operation, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

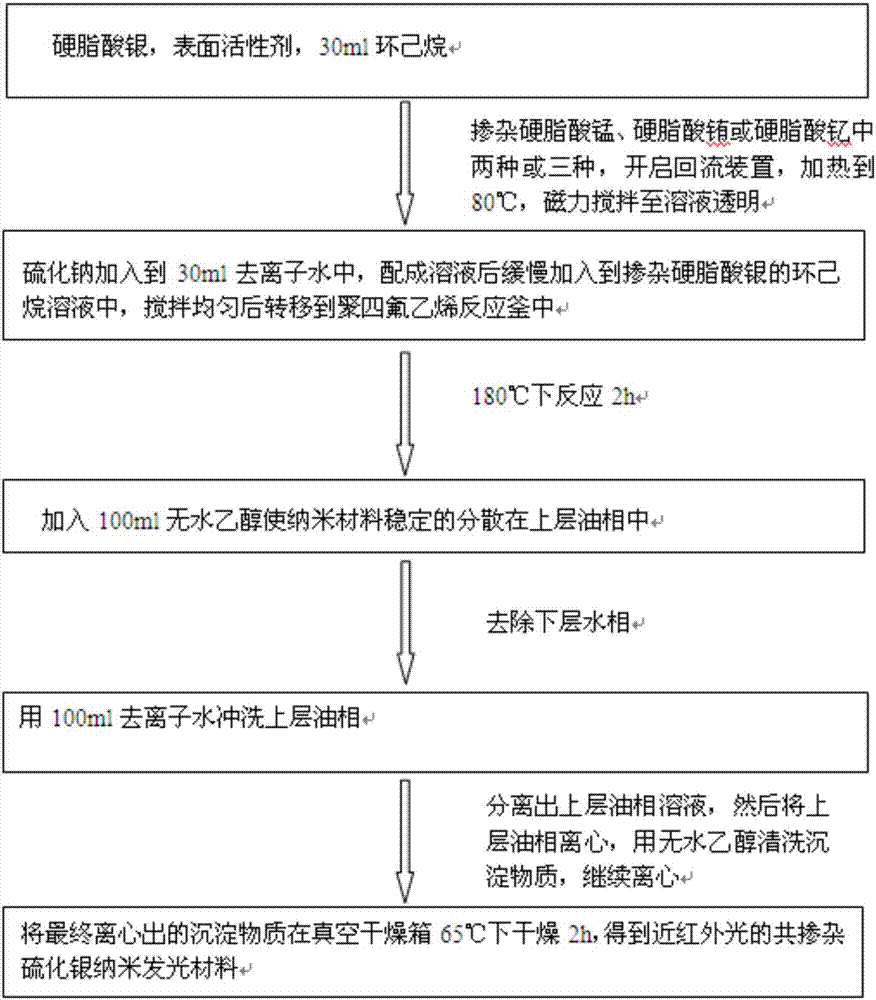

Method used

Image

Examples

Embodiment 1

[0033](1) Mix 1.24g (0.003mol) silver stearate and 0.025g manganese stearate with 0.016g, 0.06g, 0.12g europium stearate respectively, so that the molar ratio of manganese stearate to silver stearate The molar ratio of europium stearate to silver stearate is 0.8:100, 3:100, and 6:100 respectively, and it is completely dissolved in 30ml of cyclohexane at 80°C, and 3ml of oleic acid is added, and magnetically stirred To solution transparency, obtain doping manganese stearate, europium stearate and silver stearate cyclohexane solution;

[0034] (2) Take by weighing 2.16g (0.009mol) sodium sulfide, be dissolved in 30ml deionized water completely at normal temperature, stir, obtain sodium sulfide aqueous solution;

[0035] (3) the sodium sulfide aqueous solution prepared in step (2) is slowly added in the manganese stearate, europium stearate and silver stearate silver cyclohexane solution prepared in step (1), the volume of both The ratio is 1:1, stirred evenly and transferred to...

Embodiment 2

[0038] (1) Mix 1.24g (0.003mol) silver stearate and 0.228g yttrium stearate with 0.016g, 0.06g, 0.12g, 0.24g europium stearate respectively to make yttrium stearate and silver stearate The molar ratio is 8:100, the molar ratios of europium stearate and silver stearate are respectively 0.8:100, 3:100, 6:100, and 12:100, completely dissolved in 30ml cyclohexane at 80°C, Add 3ml of oleic acid, stir magnetically until the solution is transparent, and obtain a solution doped with europium stearate, yttrium stearate and silver stearate cyclohexane;

[0039] (2) Take by weighing 2.16g (0.009mol) sodium sulfide, be dissolved in 30ml deionized water completely at normal temperature, stir, obtain sodium sulfide aqueous solution;

[0040] (3) the aqueous sodium sulfide solution prepared in step (2) is slowly added to the doped europium stearate, yttrium stearate and silver stearate cyclohexane solution prepared in step (1), the volume of both The ratio is 1:1, stirred evenly and transfe...

Embodiment 3

[0043] (1) Mix 1.24g (0.003mol) silver stearate and 0.025g manganese stearate with 0.0285g, 0.1425g, 0.2851g yttrium stearate respectively, so that the molar ratio of yttrium stearate to silver stearate 1:100, 5:100, 10:100 respectively, the molar ratio of manganese stearate to silver stearate is 1:100, completely dissolved in 30ml of cyclohexane at 80°C, add 3ml of oleic acid, and magnetically stir To solution transparency, obtain doping yttrium stearate, manganese stearate and silver stearate cyclohexane solution;

[0044] (2) Take by weighing 2.16g (0.009mol) sodium sulfide, be dissolved in 30ml deionized water completely at normal temperature, stir, obtain sodium sulfide aqueous solution;

[0045] (3) the aqueous sodium sulfide solution prepared in step (2) is slowly added to the doped yttrium stearate, manganese stearate and silver stearate solution prepared in step (1), the volume of both The ratio is 1:1, stirred evenly and transferred to a polytetrafluoroethylene reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com