Semi-automatic dual-use palm fiber processing machine

A semi-automatic and dual-purpose technology, applied in the mechanical field, can solve the problems of high breaking rate, lower grade, and low integrity, and achieve the effect of high silk integrity, guaranteed integrity, and low damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

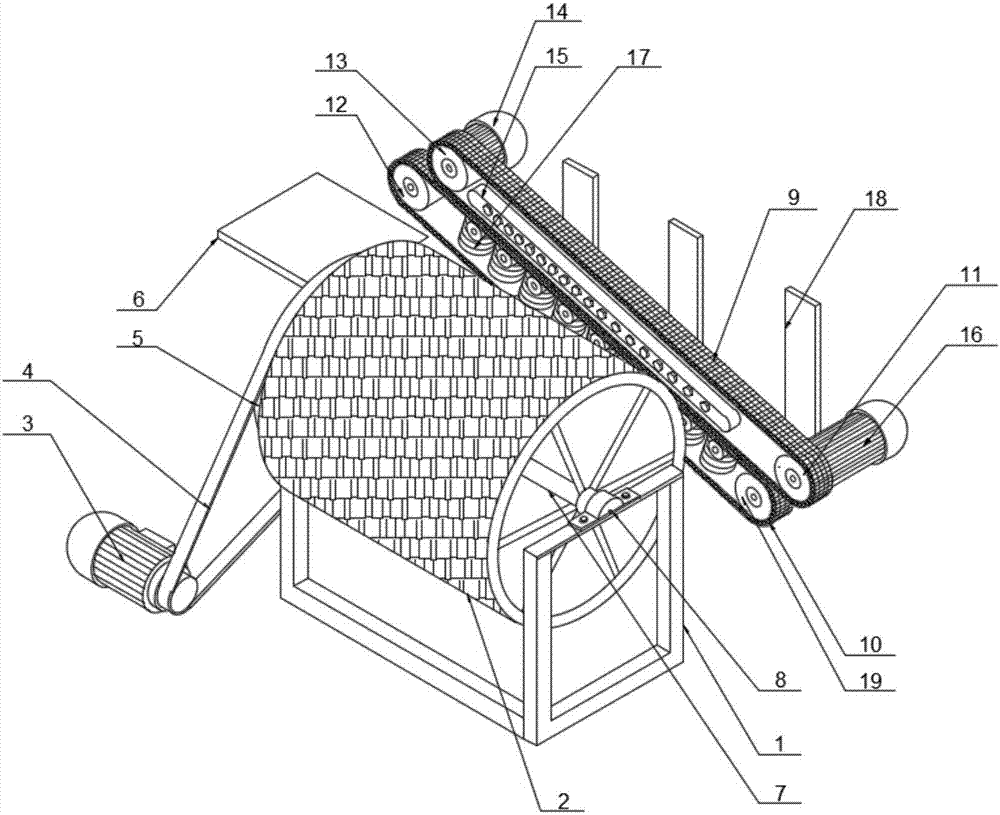

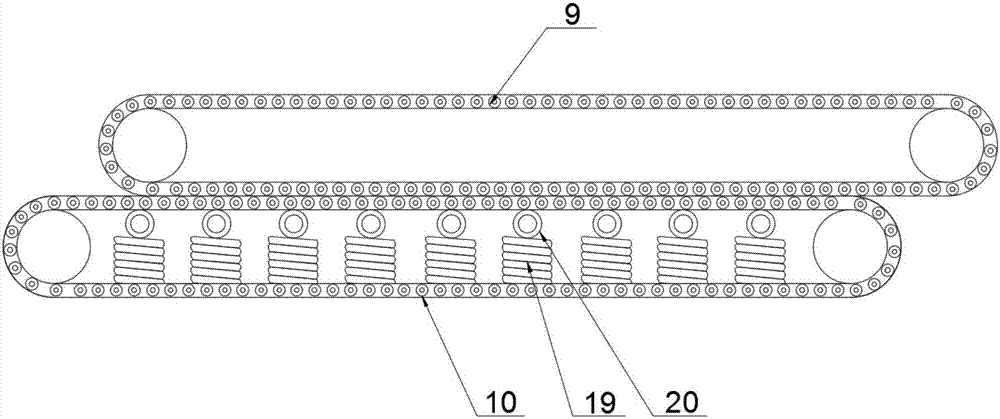

[0020] Such as Figure 1-2 As shown, the present invention provides a semi-automatic dual-purpose brown silk processing machine, comprising a frame 1, a drum 2 is installed on the frame 1, and a driving wheel 5 is coaxially arranged at one end of the drum 2, and one side of the frame 1 A main deceleration motor 3 is provided, the output shaft of the main deceleration motor 3 is connected with the driving wheel 5 through the transmission belt 4, an upper chain 9 is arranged on one side of the drum 2, and an upper chain driving wheel 11 is arranged on one end of the upper chain 9, and the upper chain The output shaft of the upper chain reduction motor 16 of the moving wheel 11 and its one end is fixedly connected, the other end of the upper chain 9 is provided with an upper chain sprocket 13, and the bottom of the upper chain 9 is provided with a lower chain 10 in parallel, and one end of the lower chain 10 A lower chain driving wheel 12 is provided, the other end of the lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com