Modular foundation pit steel truss supporting structure

A supporting structure and steel truss technology, which is applied in the direction of infrastructure engineering, roads, buildings, etc., can solve the problems that the planar layout is not well resolved, the initial investment of steel supporting structures is large, and the utilization rate of components is low, so as to avoid Diversity of component forms and specifications, easy on-site installation, and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with drawings and embodiments.

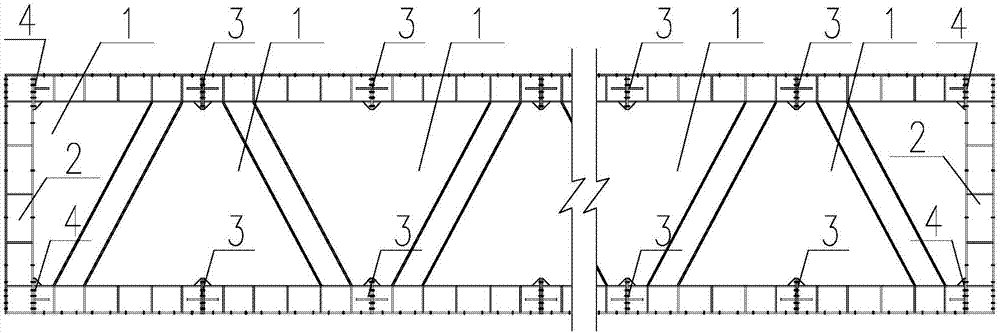

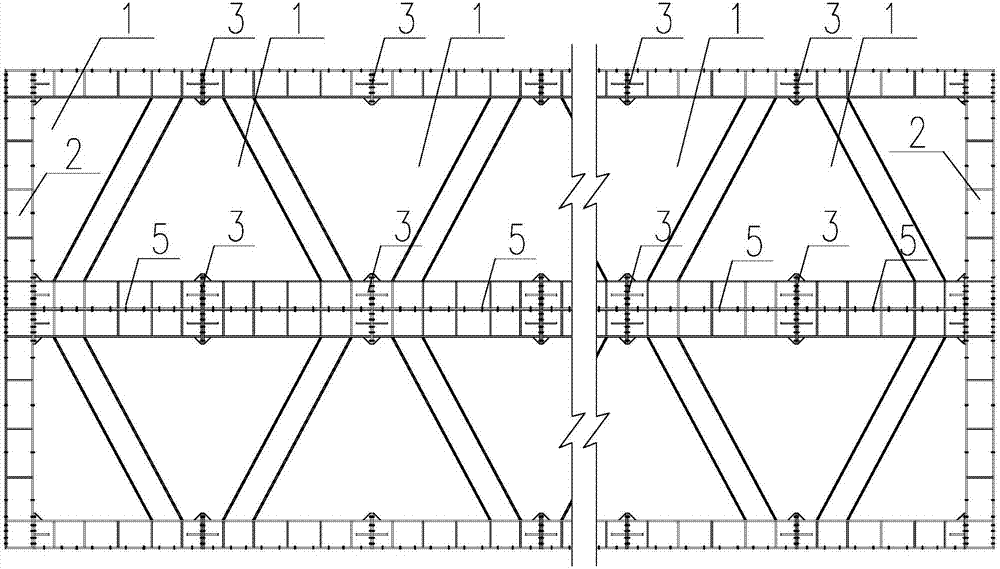

[0046] Such as figure 1 As shown, the present invention includes a single row or multiple rows of planar truss structures. The planar truss structures include basic structural units 1 and edge members 2. The planar truss structures are mainly spliced by the basic structural units 1 and are located at both ends of the planar truss structures. The basic structural unit is connected with the edge member 2, and the edge member 2 is connected with the supporting structure of the foundation pit.

[0047] The planar truss structure is formed by splicing a plurality of basic structural units 1 along a row, and two adjacent basic structural units 1 are connected by an intermediate connection node 3. After splicing, the basic structural units 1 at both ends are connected by end connection nodes 4 and edge members 2 connections.

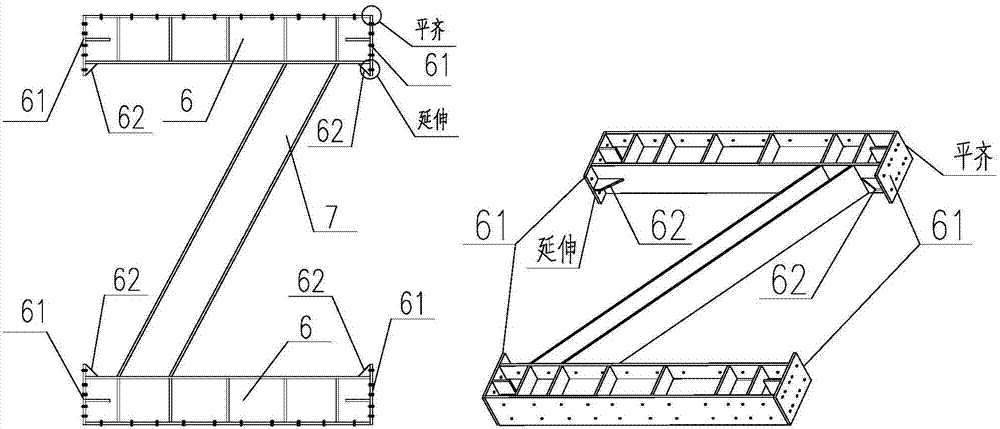

[0048] Such as Figure 3-5 As shown, the basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com