Device capable of simply adjusting clearance volume of air cylinder

A technology for clearance volume and cylinder adjustment, applied in the field of compressors, can solve the problems of violent and unstable valve opening, ins and outs of clearance volume, compressor shock, etc., and achieves controllable clearance volume, protection of air tightness, structure and so on. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

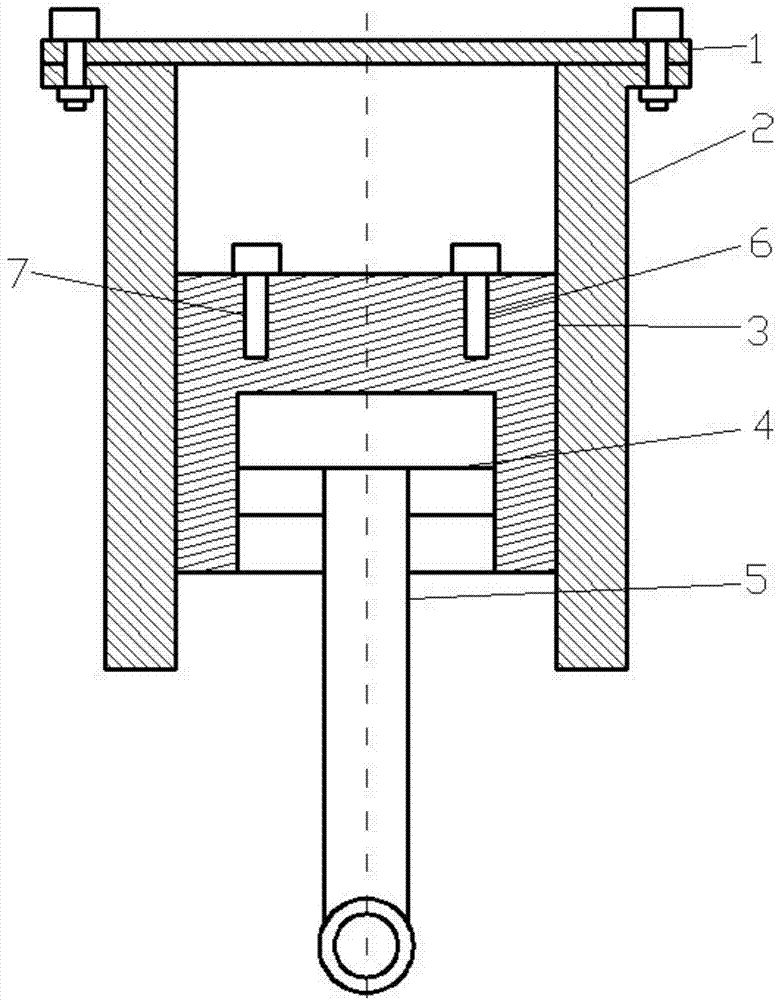

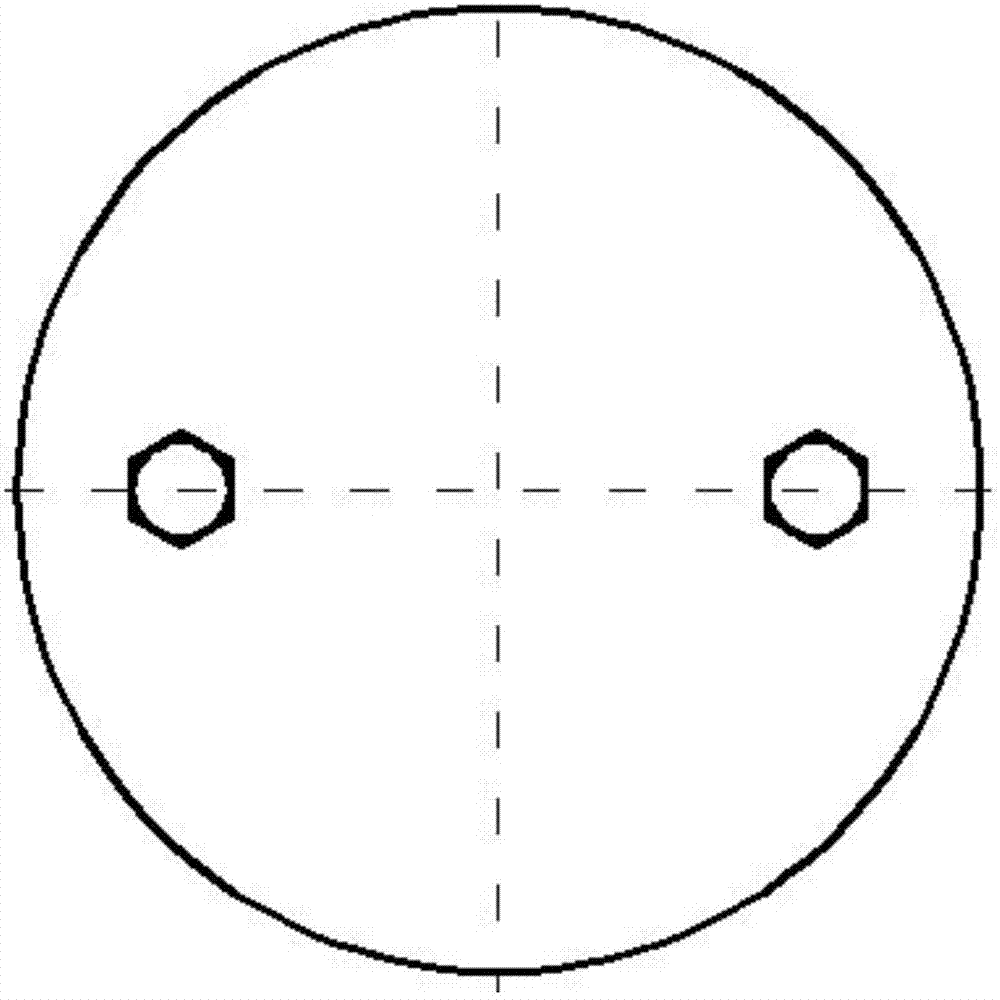

[0020] refer to Figure 1-2 , a device that can simply adjust the clearance volume of the cylinder, including a cylinder, a piston body 3 and an outer hexagonal bolt, the cylinder includes a cylinder head 1 and a cylinder body 2, the piston body 3 is located in the cylinder, and the skirt of the piston body 3 There is a piston pin 4 connected to the piston rod 5 at the top, and two screw holes are provided on the end surface of the top cover of the piston body 3 .

[0021] The two screw holes provided on the top cover end surface of the piston body 3 include a first screw hole 6 and a second screw hole 7, and the first screw hole 6 and the second screw hole 7 are connected in a straight line through the center of the top cover end surface, and It is symmetrical about the center of the circle.

[0022] The internal threads of the first screw hole 6 and the second screw hole 7 provided on the end surface of the top cover of the piston body 3 are both fine threads. The cylinder...

Embodiment 2

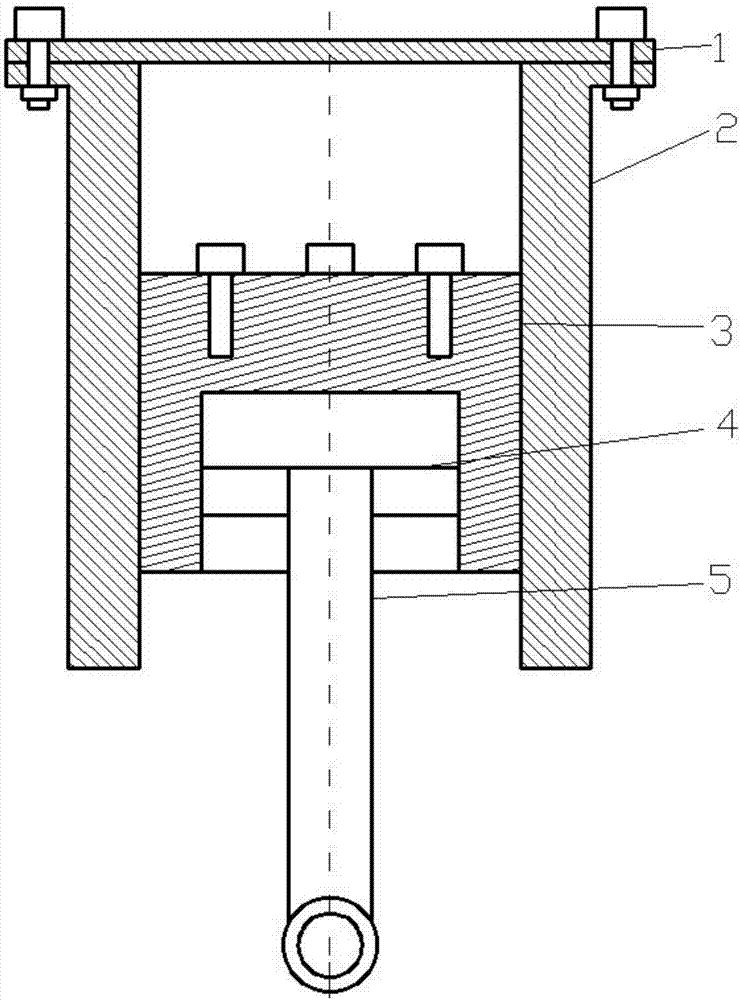

[0025] refer to Figure 3-4 , a device that can simply adjust the clearance volume of the cylinder, including a cylinder, a piston body 3 and an outer hexagonal bolt, the cylinder includes a cylinder head 1 and a cylinder body 2, the piston body 3 is located in the cylinder, and the skirt of the piston body 3 There is a piston pin 4 connected to the piston rod 5 at the top, and four screw holes are provided on the end surface of the top cover of the piston body 3 .

[0026] The four screw holes provided on the end surface of the top cover of the piston body 3 are arranged in an annular array with the center of the top cover end surface of the piston body 3 as the base point.

[0027] The internal threads of the four screw holes provided on the end surface of the top cover of the piston body 3 are all fine threads. The cylinder head 1 and the cylinder body 2 of the cylinder are flanged. The gap between the end surface of the top cover and the cylinder passage of the piston bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com