Projection keyboard real time dynamic automation calibration method

A projection keyboard, real-time dynamic technology, applied in image data processing, instruments, calculations, etc., can solve the problems of inconsistent fingertip coordinate extraction, different calibration results, installation errors, etc., to eliminate different calibration results, improve calibration efficiency, and save money The effect of labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

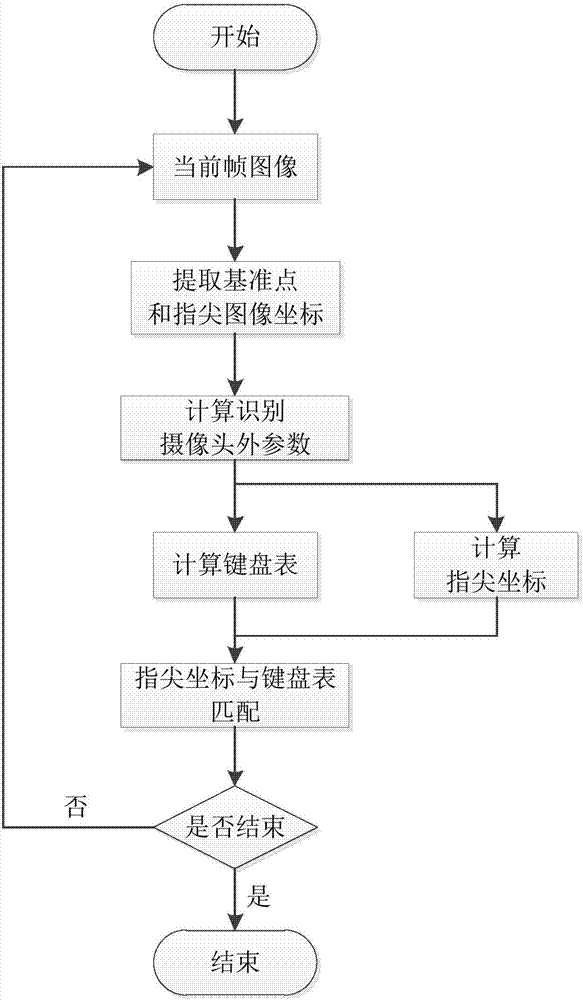

[0048] Specific implementation mode one: combine image 3 To describe this embodiment,

[0049] A real-time dynamic automatic calibration method for a projection keyboard, comprising:

[0050] Step 1. Camera calibration:

[0051] Camera calibration is the calibration of the recognition camera, which is used for fingertip area recognition and positioning;

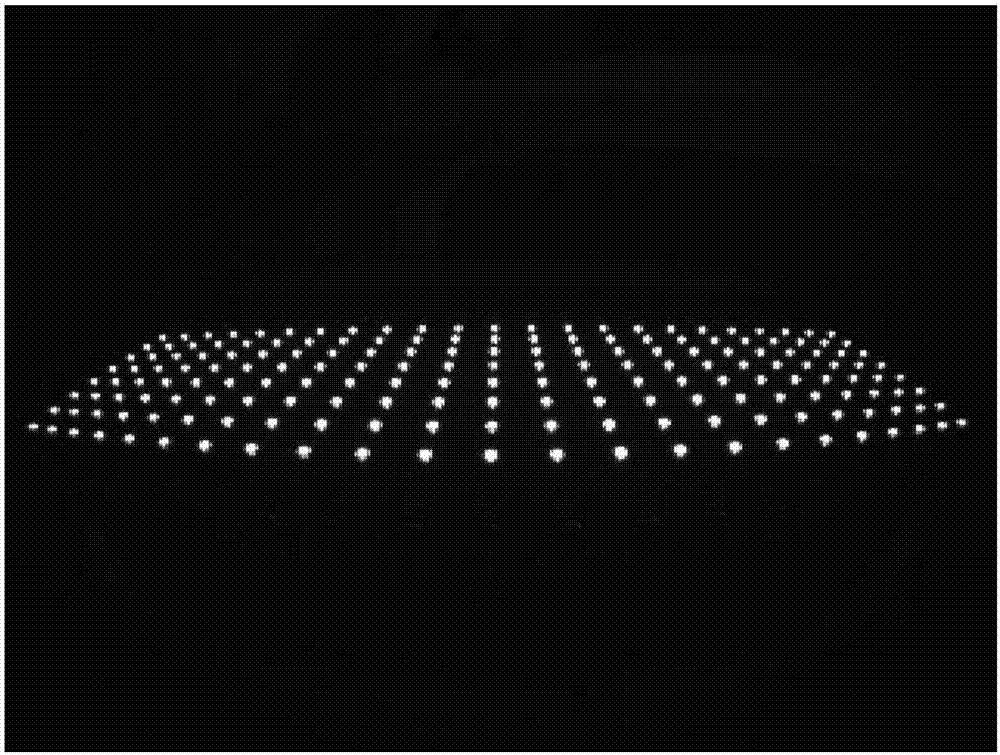

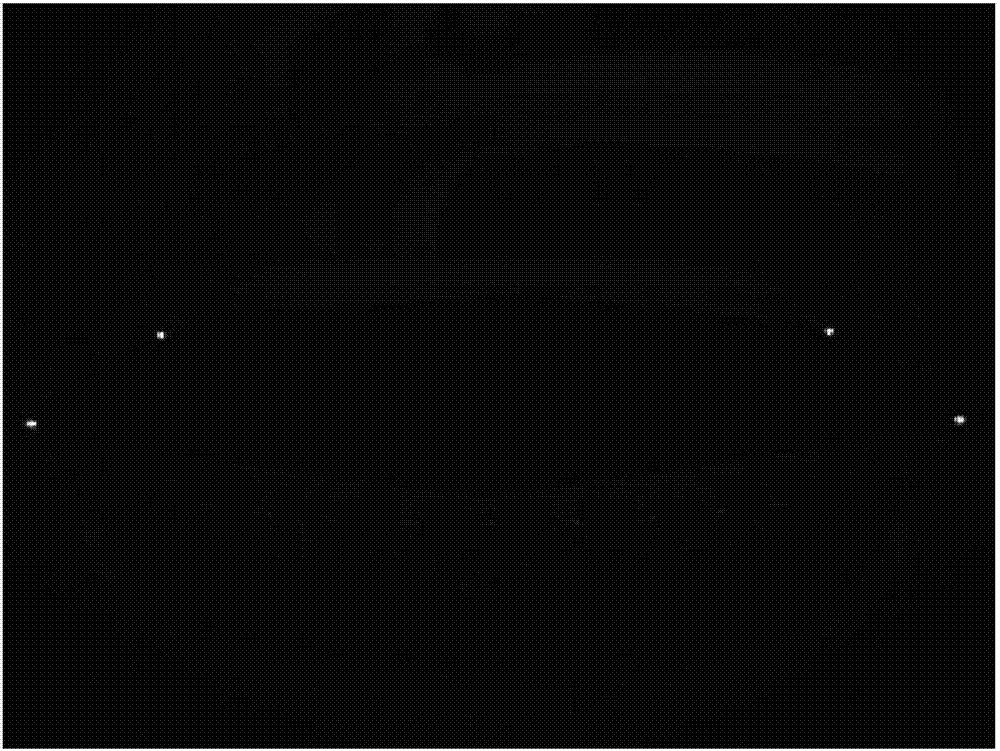

[0052] The calibration uses a customized LED small light board with known distribution size as the LED calibration board, and uses the recognition camera to take a picture of the LED calibration board, such as figure 1 As shown, the threshold segmentation algorithm is used to detect each light point on the LED calibration board, and the centroid of the light point is calculated as the coordinate of the calibration point in the image, that is, the image coordinates of the calibration point; at the same time, since the size of the LED calibration board is known, the LED The world coordinates of each light point on the calibra...

specific Embodiment approach 2

[0064] A real-time dynamic automatic calibration method for a projection keyboard, comprising:

[0065] Step 1. Camera calibration:

[0066] Camera calibration is the calibration of the recognition camera, which is used for fingertip area recognition and positioning;

[0067] The calibration uses a customized LED small light board with known distribution size as the LED calibration board, and uses the recognition camera to take a picture of the LED calibration board, such as figure 1 As shown, the threshold segmentation algorithm is used to detect each light point on the LED calibration board, and the centroid of the light point is calculated as the coordinate of the calibration point in the image, that is, the image coordinates of the calibration point; at the same time, since the size of the LED calibration board is known, the LED The world coordinates of each light point on the calibration board are known; according to the known image coordinates and world coordinates of t...

specific Embodiment approach 3

[0083] The process of calculating the world system coordinates of each button according to the overall size of the projected keyboard, the size of each button and the world coordinate system of the four calibration reference points described in step 5 of this embodiment includes the following steps:

[0084] The projected keyboard includes 6 rows of buttons and the mouse area on the right side of all the buttons; assuming that the 6 rows of buttons of the projected keyboard are respectively provided with n1, n2, n3, n4, n5 and n6 buttons, the coordinates of the buttons are calculated as follows:

[0085] Coordinate calculation of the first row of buttons:

[0086] The width of each key in the first row of n1 keys is x1, the height of the key is h1, the gap between the key levels is d1, the world coordinates of the upper left vertex of the projection keyboard are (x, y, z), and the The abscissa of the upper left vertex is (x1+d1)*(i1-1), where i1 represents the serial number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com