A kind of equipment and method for preparing annular hot extrusion material

A technology of hot extrusion and equipment, which is applied in the manufacture of motor generators, stator/rotor bodies, inductors/transformers/magnets, etc. It can solve problems such as low efficiency and difficulties in large-scale production of molds, and achieve efficiency improvement and replacement simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

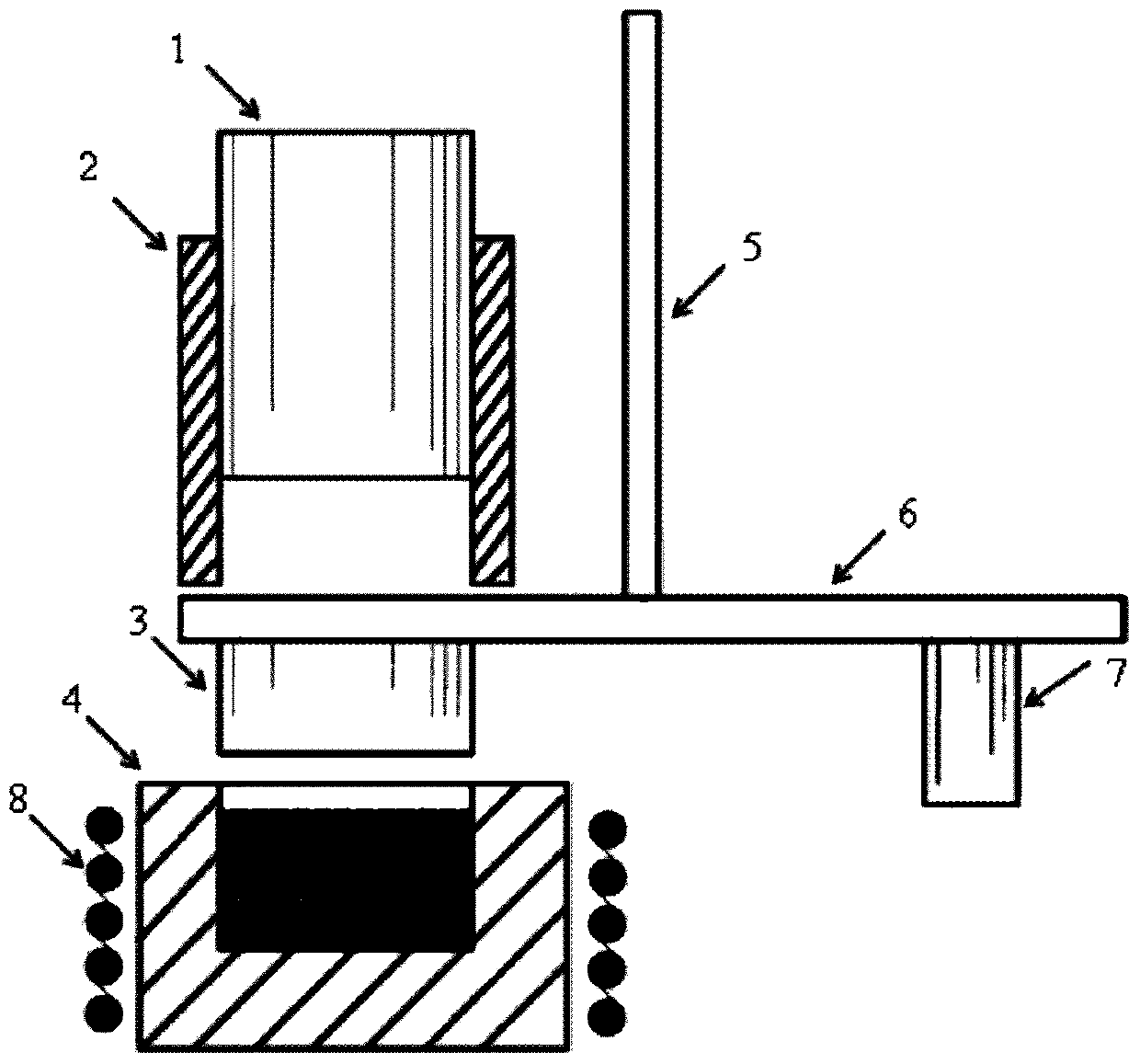

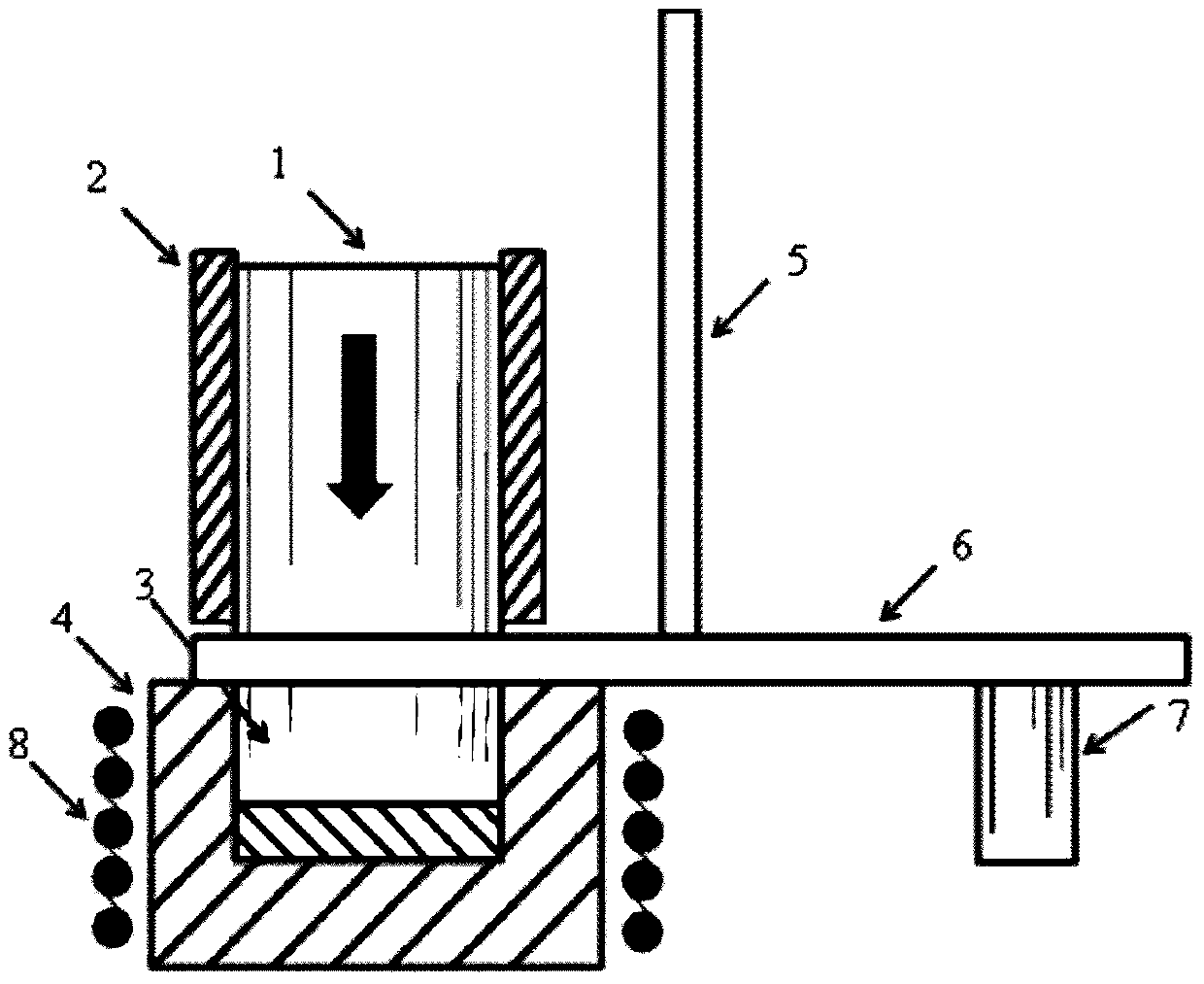

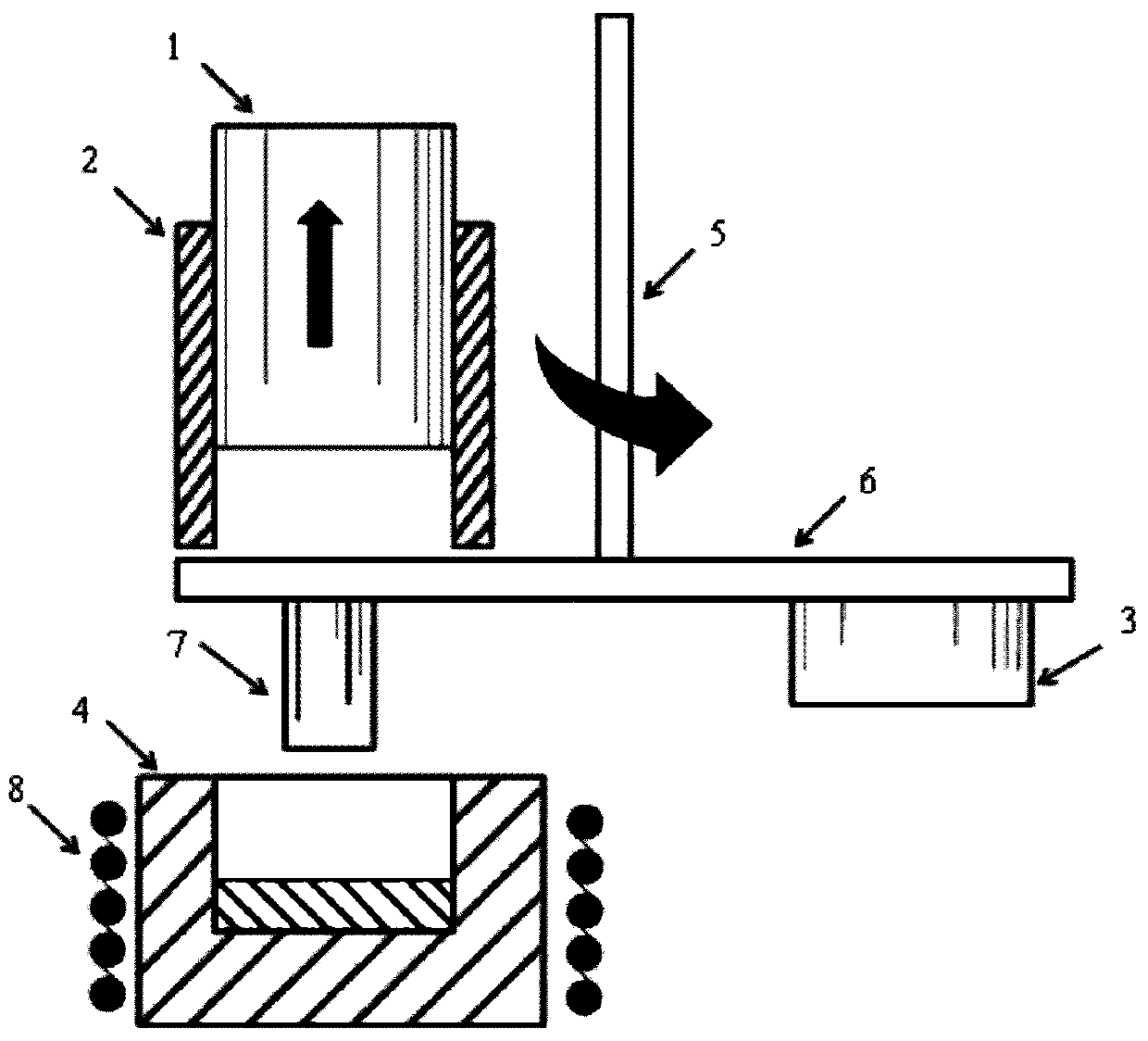

[0025] The equipment of the present invention such as figure 1 Described, specifically include die system, punch system, hydraulic system, die system includes die 4, and around the heating device 8 outside die; A rotary rod 5 that rotates the punch 3 and the fixed part 6, the punch system can move up and down with the hydraulic punch 1; the hydraulic system includes a hydraulic punch 1, and the punch 1 moves up and down along the positioning device 2. The concave mold system is mainly used to hold the powder, form the outer diameter of the final magnet, and use the heating device 8 to heat the concave mold 4 and the materials in it. The heating method of the heating device 8 is resistance and induction heating. Resistance heating is preferred. Its advantages The reason is that the temperature of the material in the die 4 can be precisely cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com