Soil crushing workpiece capable of improving land crushing efficiency

A technology of high efficiency and crushing soil, which is applied in the direction of farming machinery, agricultural machinery, agricultural machinery and machinery, etc., can solve the problems of reducing work efficiency and soil crushing cannot be carried out normally, so as to improve work efficiency, improve land crushing efficiency, and prevent soil splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

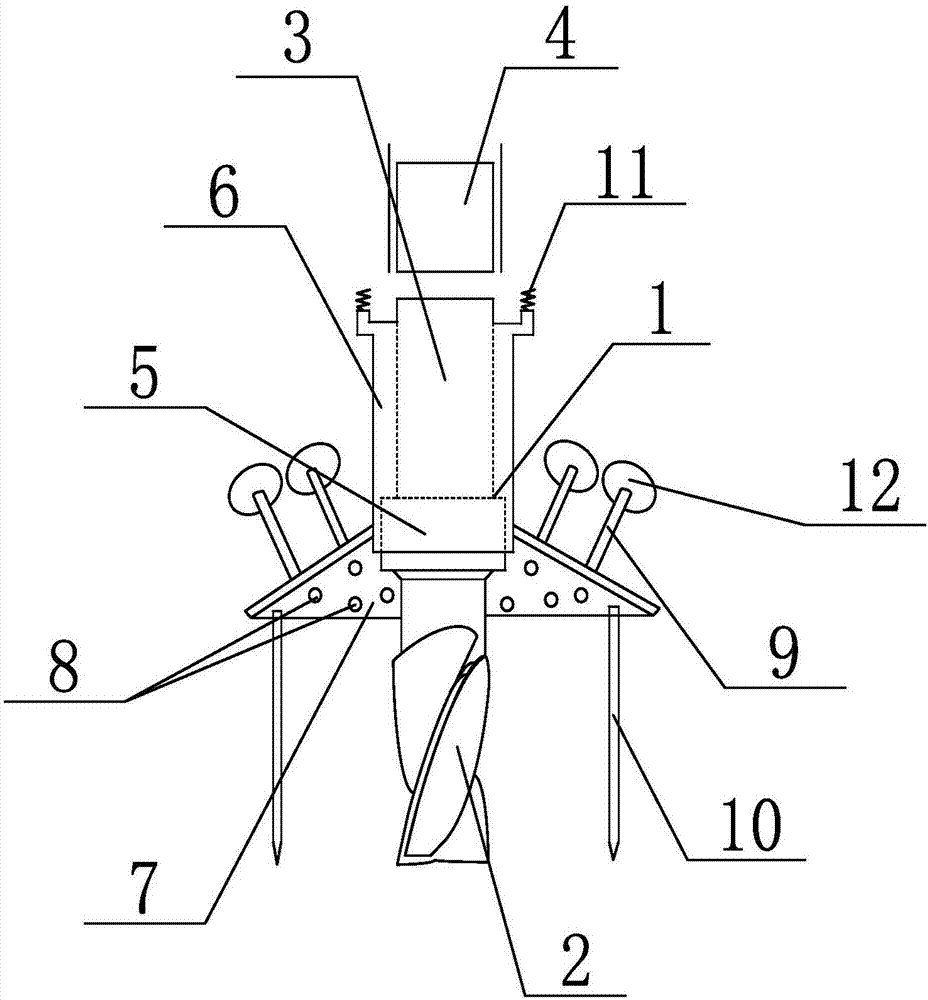

[0021] Such as figure 1 As shown, the broken earth workpiece that the present invention improves land crushing efficiency comprises cutter head body 1, and cutter head body 1 comprises keyway cutter 2 and transmission shaft 3, and one end of described transmission shaft 3 is used for connecting power unit 4, and keyway cutter 2 It is connected with the transmission shaft 3 through the bearing 5, and the transmission shaft 3 and the bearing 5 are covered with a movable scraper 6, the inner wall of the movable scraper 6 is slidingly connected with the outer wall of the bearing 5, and the movable scraper 6 can slide up and down; The outer wall of the scraper 6 is covered with an umbrella-shaped splash guard 7, and the inner wall of the splash guard 7 is connected with a plurality of vertically arranged ejector rods 10, and the plurality of ejector rods 10 surround the axis of the keyway cutter 2. Distributed in a ring, the bottom end of the ejector rod 10 is flush with the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com