Automatic cleaning system for conveyer belt

An automatic cleaning and conveyor belt technology, which is applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve the problems of heavy scraper quality, material waste, and affecting the cleaning effect, so as to achieve thorough cleaning and ensure the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

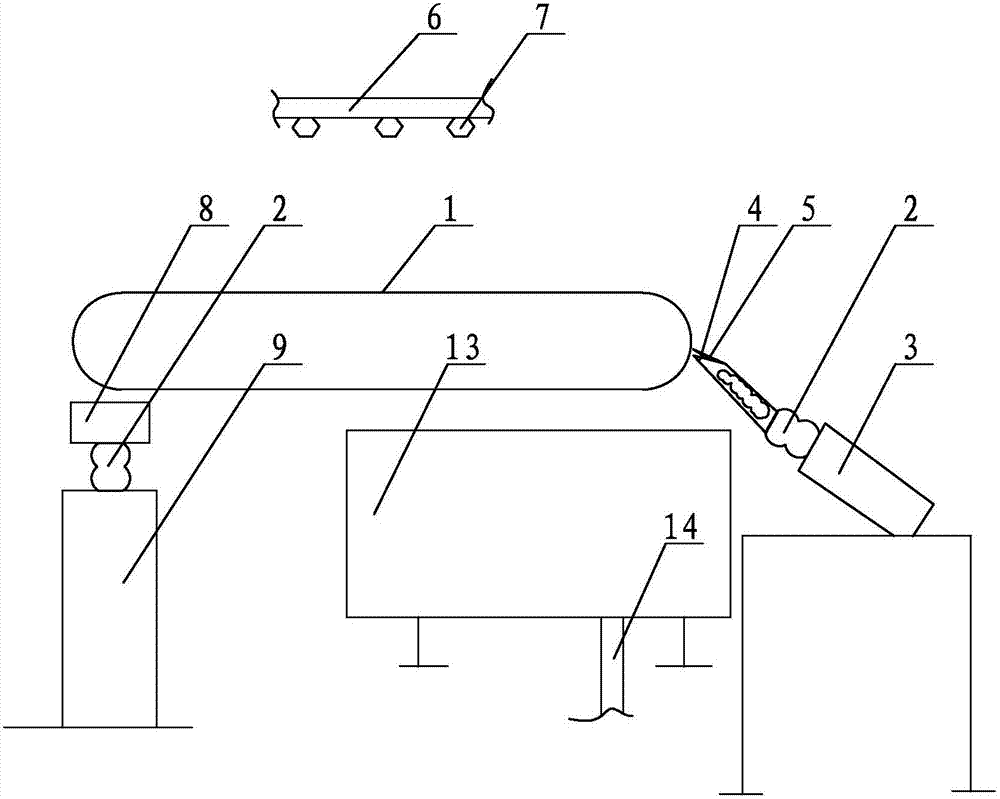

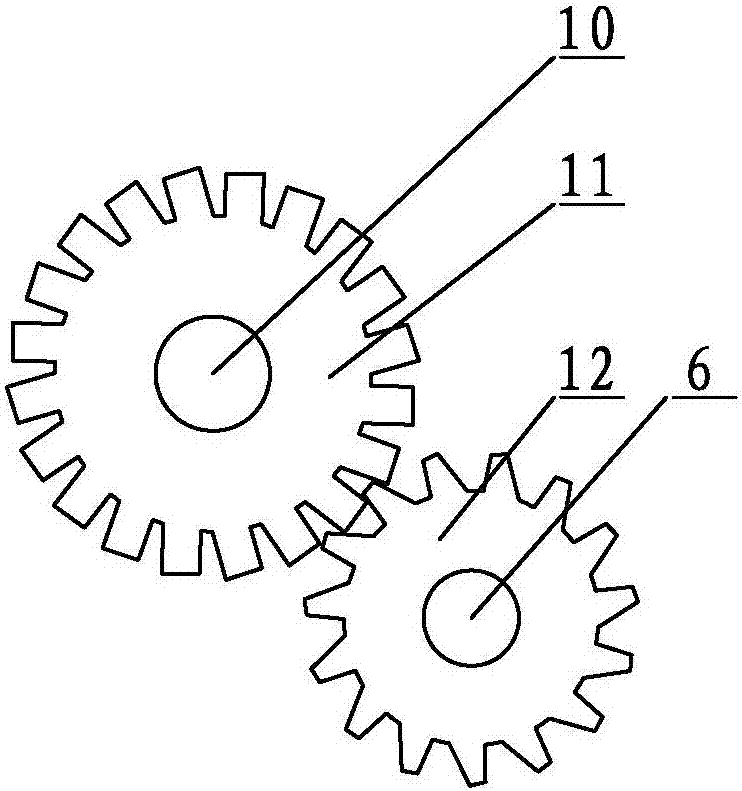

[0025] Such as figure 1 As shown, the conveyor belt automatic cleaning system of the present invention includes a conveyor belt 1 and a plastic scraper. A plastic scraper is provided at one end of the conveyor belt 1. The plastic scraper is oriented opposite to the transmission direction of the conveyor belt 1. The plastic scraper is connected by an air spring 2. A scraper drive assembly 3, a pressure sensor is set between the air spring 2 and the plastic scraper, the plastic scraper includes a primary scraper 4 and a secondary scraper 5, the primary scraper 4 and the secondary scraper 5 are set as an integral structure, so The non-bearing parts of the primary scraper 4 and the secondary scraper 5 are set as hollow structures, and the water spray pipe 6 is correspondingly arranged above the conveyor belt 1, and the water spray pipe 6 is connected to the rotating assembly, and the spray nozzle 6 is provided corresponding to the conveyor belt 1. 7. The other end of the conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com