Bulb with self-forming LED light source

A LED light source and self-forming technology, applied in the direction of light source, slender light source, light source fixation, etc., can solve the problems of reduced processing efficiency, complicated installation process, and increased cost, so as to improve processing efficiency, simplify internal structure, and increase heat dissipation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

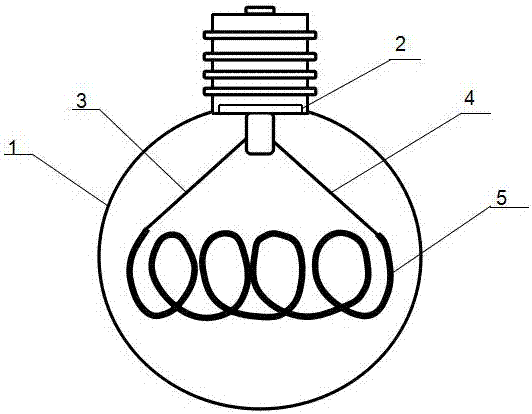

[0035] by figure 1 It can be seen that a light bulb with a self-forming LED light source includes a light bulb shell 1 made of transparent or partially transparent glass, with any shape, inflated or not inflated inside, and a power driver 2 is provided at the back of the bulb shell 1. The power supply positive pole 3 and the power negative pole 4 are provided at both ends of the power driver 2, and also includes a self-forming LED light source arranged in the bulb shell in a horizontal, vertical or diagonal direction. The two ends of the self-forming LED light source The positive pole and negative pole of the power supply are respectively provided. The positive pole and the negative pole of the power supply are electrically connected with the positive pole 3 of the power supply and the negative pole 4 of the power supply. The so-called electrical conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com