Dinitrogen tetroxide/hydrazine propellant exhaust gas waste liquid treatment burner and control method

A dinitrogen tetroxide and waste liquid treatment technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve problems such as environmental pollution, personnel safety hazards, waste gas and waste liquid treatment devices cannot be shared, and achieve structural strength Good, high reliability, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

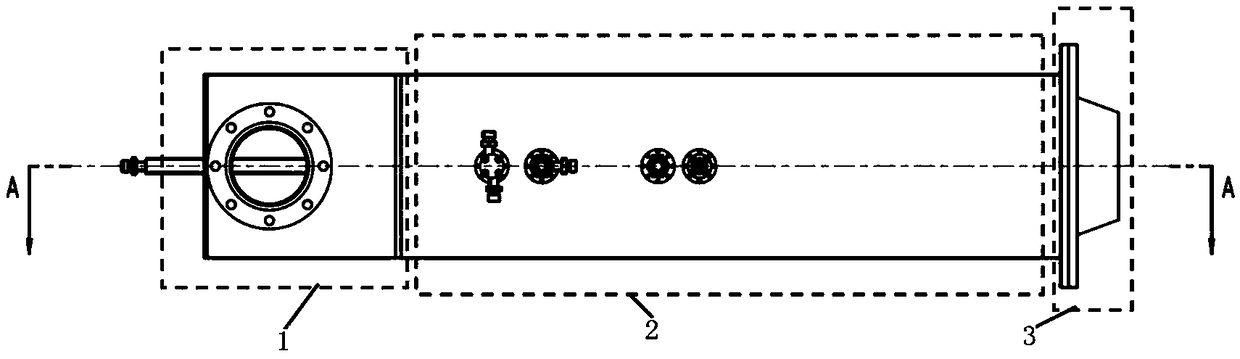

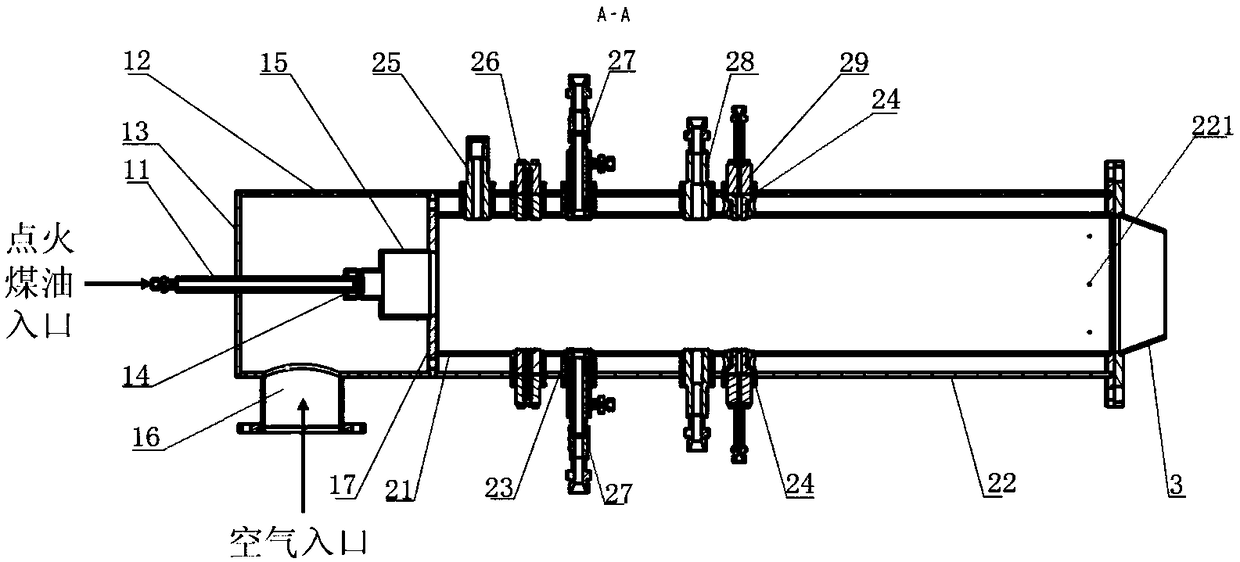

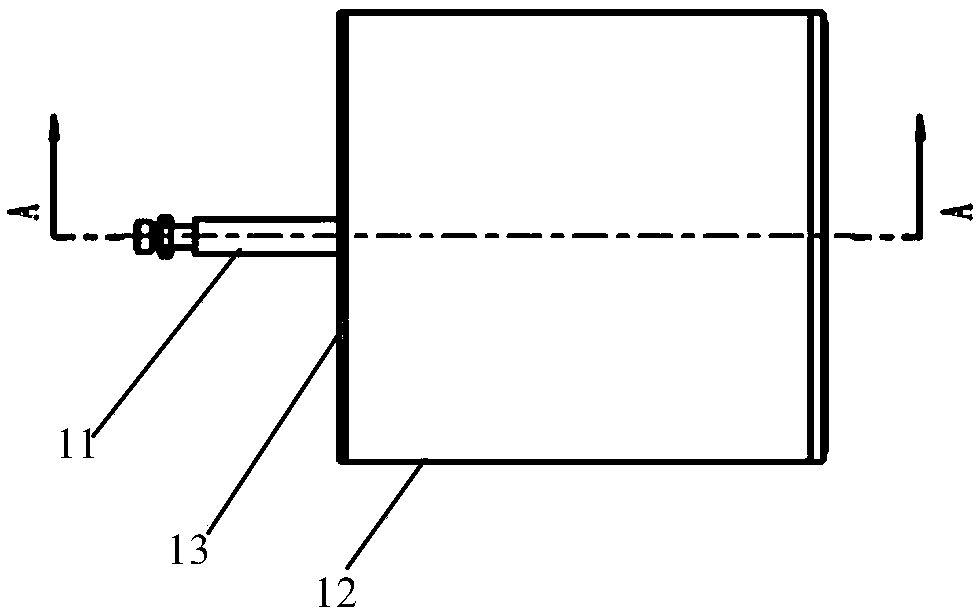

[0060] The present invention proposes a device for the treatment of dinitrogen tetroxide / hydrazine propellant waste gas and waste liquid, aiming at the current situation that there is no device capable of processing dinitrogen tetroxide waste gas and waste liquid as well as hydrazine propellant waste gas and waste liquid. The burner includes a head 1 for igniting premixed gas, a body 2 for waste gas and waste liquid treatment, and a tail nozzle 3. The head 1 is located at the front end of the body 2 and the body 2 is coaxially installed, and the tail nozzle 3 is located at the end of the body 2 and installed coaxially with the body 2, see figure 1 and figure 2 , the head 1 provides kerosene / air premixed gas for ignition, and the body 2 mainly burns the waste gas and waste liquid that needs to be treated; the head inner pipe 11 and the head outer pipe 12 are coaxially installed, and the front part of the head inner pipe 11 The position is equipped with a welding straight-thro...

Embodiment 2

[0064] The structure and overall scheme of the burner used for the treatment of dinitrogen tetroxide / hydrazine propellant waste gas and waste liquid are the same as in Embodiment 1, the difference is that the ignition kerosene nozzle 14 is a tangential hole single-component centrifugal nozzle, which can ensure that the kerosene atomization fineness. The ignition kerosene enters from the ignition kerosene channel through the tangential hole of the ignition kerosene nozzle 14, and is sprayed into the atomization zone from the outlet of the nozzle for secondary atomization and mixing under the action of ignition air, and the mixed gas is further mixed and ignited in the mixing zone to form High temperature rich combustion gas. The ignition air channel is a straight hole evenly distributed on the side of the front section of the step-shaped mixing tube. In this example, the cross-section of the hole is circular.

Embodiment 3

[0066] The structure and general scheme of the burner used for the treatment of dinitrogen tetroxide / hydrazine propellant waste gas and waste liquid are the same as those in Embodiments 1 and 2. The head inner tube 11, the head outer tube 12, the secondary air equalizing plate 17, the body Part inner pipe 21, body outer pipe 22, tail nozzle 3, module mounting seat 23 without air channel, module mounting seat 24 with air channel, N 2 o 4 Waste liquid treatment module 26, N 2 o 4 Waste gas treatment module 27, hydrazine waste gas treatment module 28, hydrazine waste liquid treatment module 29, ignition kerosene nozzle 14, stepped mixing tube 15, igniter seat 25 and head cover 13 are all made of stainless steel; 2 o 4 Waste liquid treatment module 26, N 2 o 4 The waste gas treatment module 27, the hydrazine waste gas treatment module 28, and the hydrazine waste liquid treatment module 29 are threadedly connected to the installation seat, which is convenient for disassembly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com