Encapsulation method capable of preventing rising of internal resistance of ultrathin polymer battery

A technology of battery internal resistance and packaging method, applied in battery assembly, secondary battery manufacturing, battery pack components, etc., can solve problems such as battery temperature rise and electrolyte damage, reduce heat sealing area and reduce heat The effect of generating and maintaining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

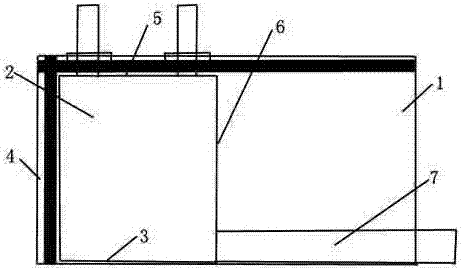

[0032] Such as Figure 1-6 As shown, a packaging method to prevent the internal resistance of ultra-thin polymer batteries from increasing, uses 1 heat-sealing film to perform hot-press packaging on 2 ultra-thin batteries, and uses the following steps to package 2 ultra-thin batteries:

[0033] A, such as figure 1 As shown, wrap 2 ultra-thin batteries with 1 heat-sealing film, and heat-press seal 1 heat-sealing film on three sides of 2 ultra-thin batteries (3, 4, 5);

[0034] B isolating 1 heat-sealing film on the remaining side of 2 ultra-thin batteries 6 with 7 separators, the longitudinal height of the 7 separators being less than 1 / 5 of the height of 2 ultra-thin batteries;

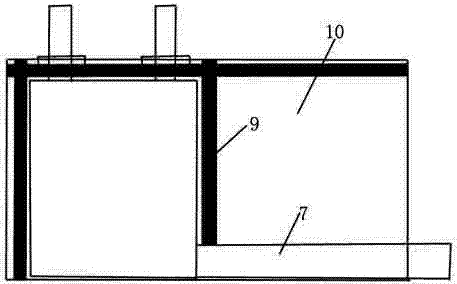

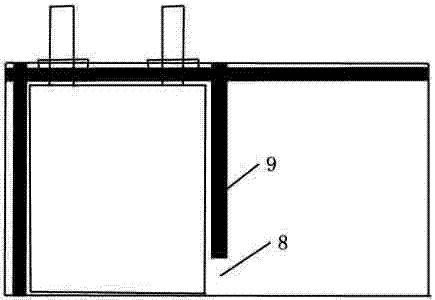

[0035] C as figure 2 As shown, the heat-sealing film on the remaining side of 6 in step B is heat-press-packaged to form 9 packaging lines, and the width of the heat-sealing film on the remaining side of the 2 ultra-thin batteries 6 is greater than that of 2 ultra-thin batteries. The width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com