Multi-stage structure electric excitation synchronous start/generator initial position detection method

A technology of initial position detection and synchronous starting, which is applied in the direction of motor generator control, generator control, and electromechanical transmission control. The effect of direct detection, simple calculation process and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

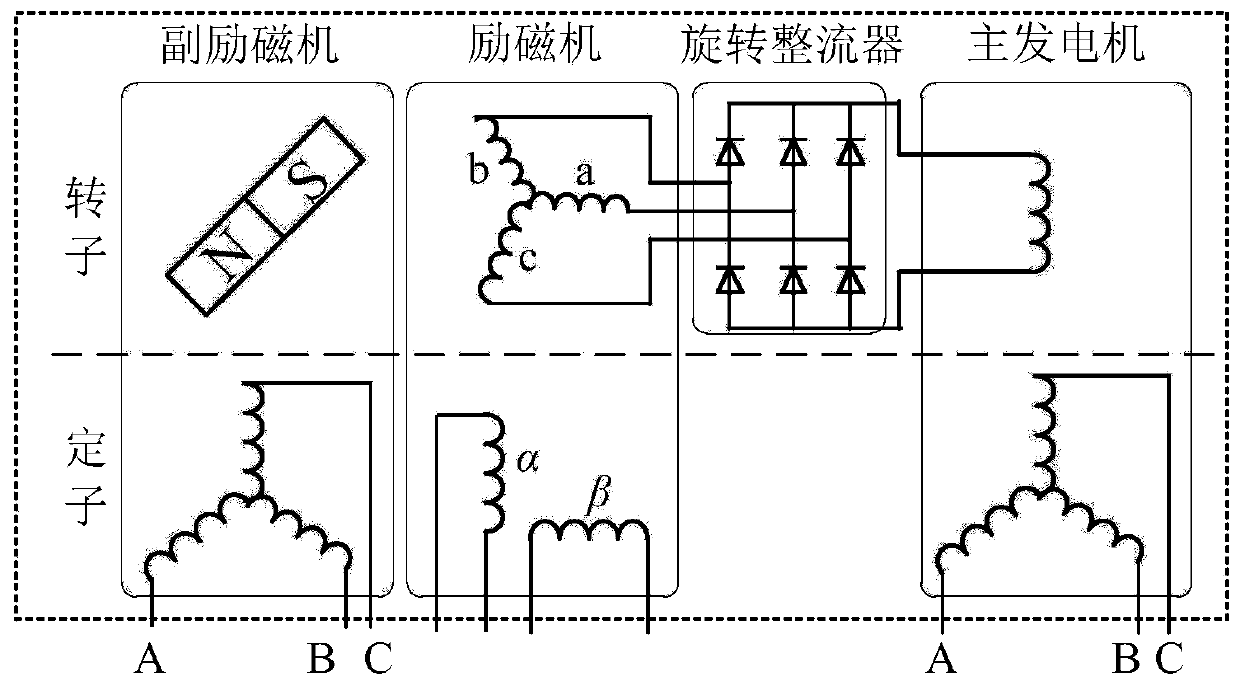

[0038] The present invention will now be further described in conjunction with the embodiments and drawings:

[0039] The specific steps included in the embodiment are as follows:

[0040] Step 1: Use a magnetic powder brake to fix the motor rotor, and apply an AC excitation voltage with a phase difference of 90° to the two-phase exciter. The voltage amplitude is 90V and the angular frequency is 200Hz;

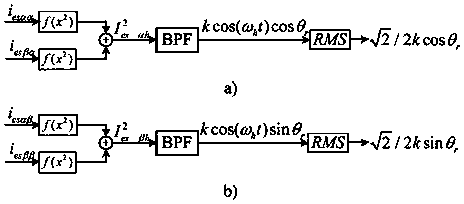

[0041] Step 2: Estimate the rotor position angle value, as follows:

[0042] 2.1) Inject a high-frequency square wave voltage with an amplitude of 20V and an angular frequency of 1.25KHz into the α axis of the main generator as follows:

[0043]

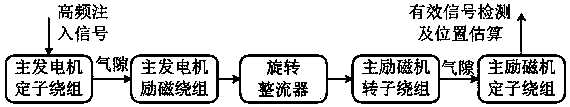

[0044] Where T h =0.0008s, ω h =2.5πrad / s; The high frequency response signal of the main generator stator is transmitted to the exciter stator through the main generator rotor, rotating rectifier, and exciter rotor in turn. The effective rotor position signal extracted from the exciter stator is obtained after relevant processing The cosine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com