Circuit board welding clamp for charging pile production

A welding fixture and circuit board technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve good insulation protection measures, expand the scope of use, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

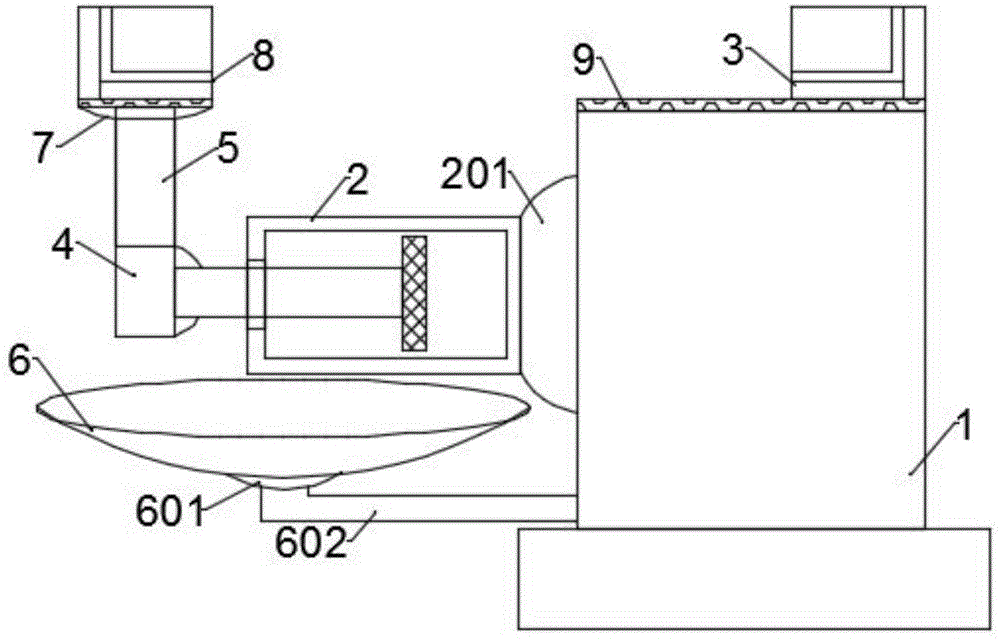

[0024] like figure 1 As shown, the present invention provides a circuit board welding fixture for charging pile production, including a fixture main frame 1, and a hydraulic cylinder 2 is provided on one side of the fixture main frame 1, wherein the hydraulic cylinder 2 is fixed by a cylinder frame 201 It is installed on the side surface of the clamp main frame 1, and the top of the clamp main frame 1 is equipped with a fixed splint 3, and the piston rod of the hydraulic cylinder 2 is connected with a movable support 5 through a supporting base plate 4, which can be controlled by controlling the hydraulic cylinder. 2 to change the distance between the movable support 5 and the fixture main frame 1 to meet the requirements of the circuit board, and a collation disk 6 is arranged directly below the hydraulic cylinder 2, wherein the center of the collation disk 6 directly below A support base 601 is installed, and the support base 601 is fixedly installed on the side surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com