Construction method for extra-deep foundation pit underground continuous wall

A technology of underground diaphragm wall and construction method, which is applied in basic structure engineering, sheet pile wall, earth mover/shovel, etc., can solve the problems affecting the accuracy and stability of underground wall groove formation, low strength and high compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

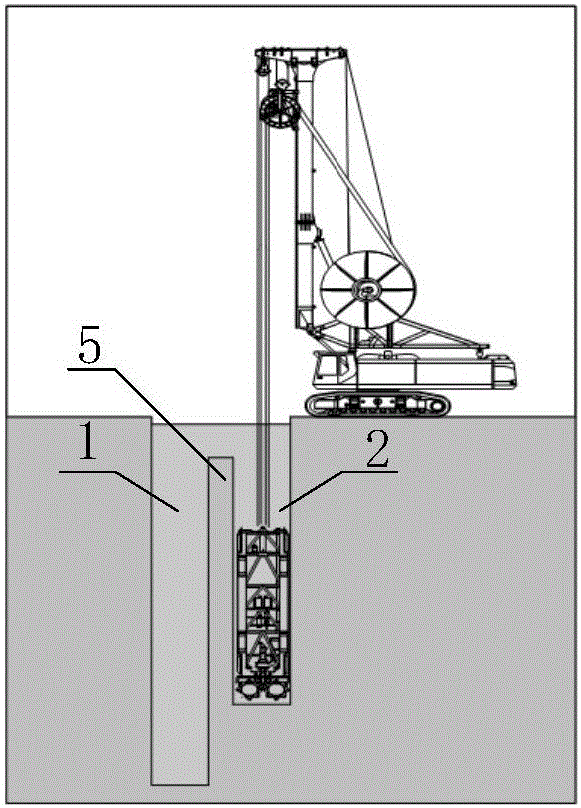

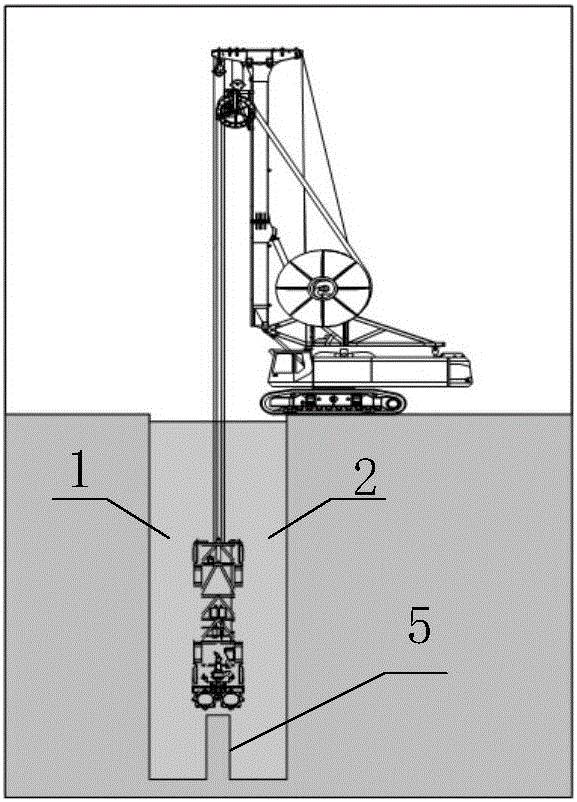

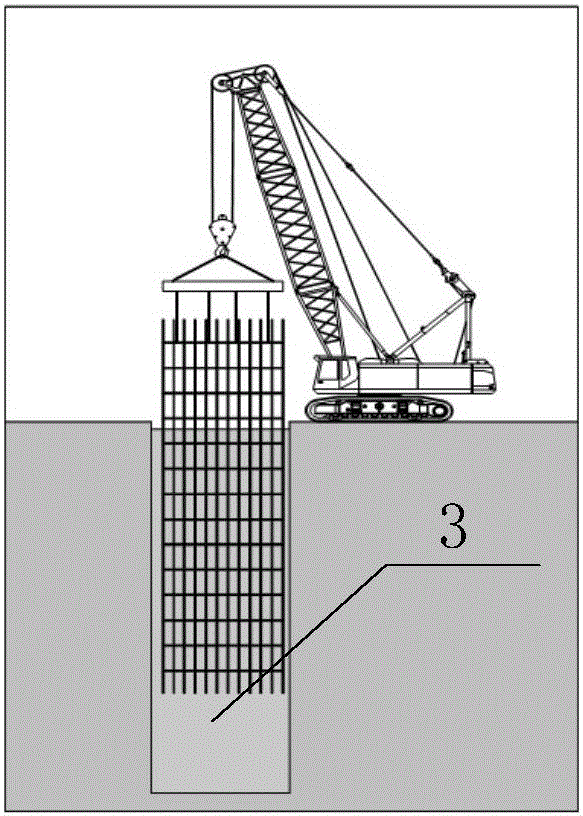

[0032] A kind of underground diaphragm wall construction method of the present invention, such as Figure 9 As shown, it mainly includes the construction preparation process, the groove forming process, the hole cleaning and grouting process, the joint wall brushing process, and the reinforcement cage installation and grouting process.

[0033] Among them, the construction preparation process is: find out the specific location of the foundation piles of the house before construction, and take excavation treatment and replacement measures for the existing shallow obstacles. Grouting reinforcement measures.

[0034] For the pile foundation within 1.0m of the left and right of the underground wall, use a vibrating hammer to clamp the channel steel to insert from around the pile to reduce the friction force of the pile, and then use a 600mm diameter locking p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com