Assembling type corrugated sheet steel and concrete combination comprehensive pipe gallery

A technology of corrugated steel plate and comprehensive pipe gallery, which is applied in construction, artificial islands, and infrastructure engineering, etc., can solve the problems of reinforced concrete structures such as heavy weight, difficult assembly process, and limited transportation length, so as to save design cycle and eliminate the need for The maintenance cycle and the effect of improving the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of this patent will be described in detail below in conjunction with accompanying drawings 1 to 5 .

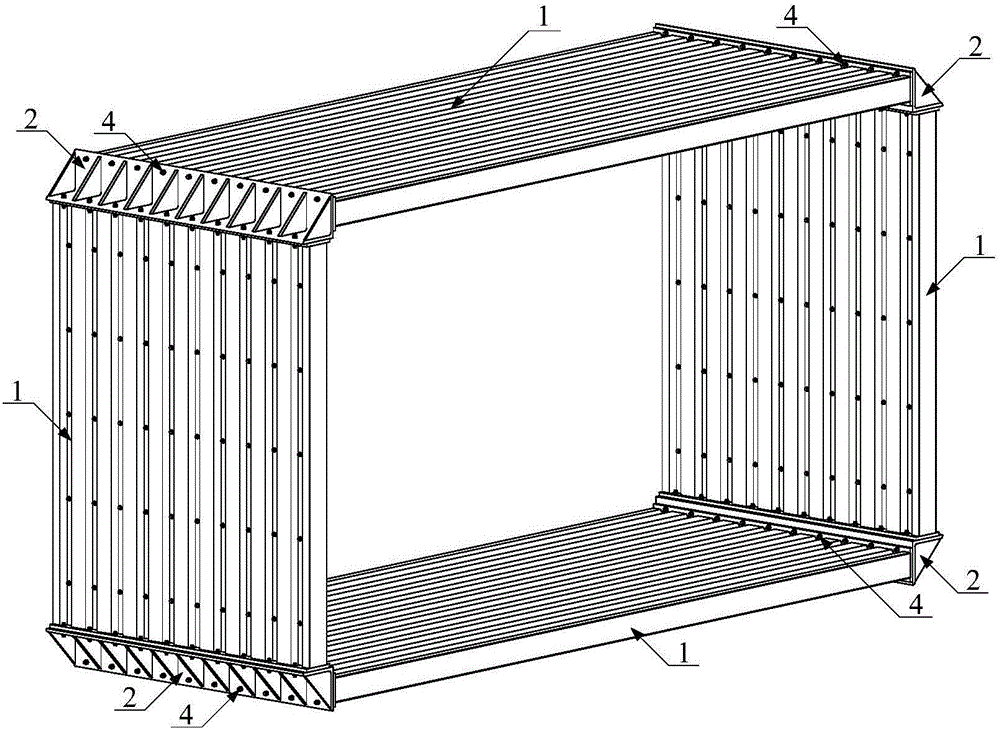

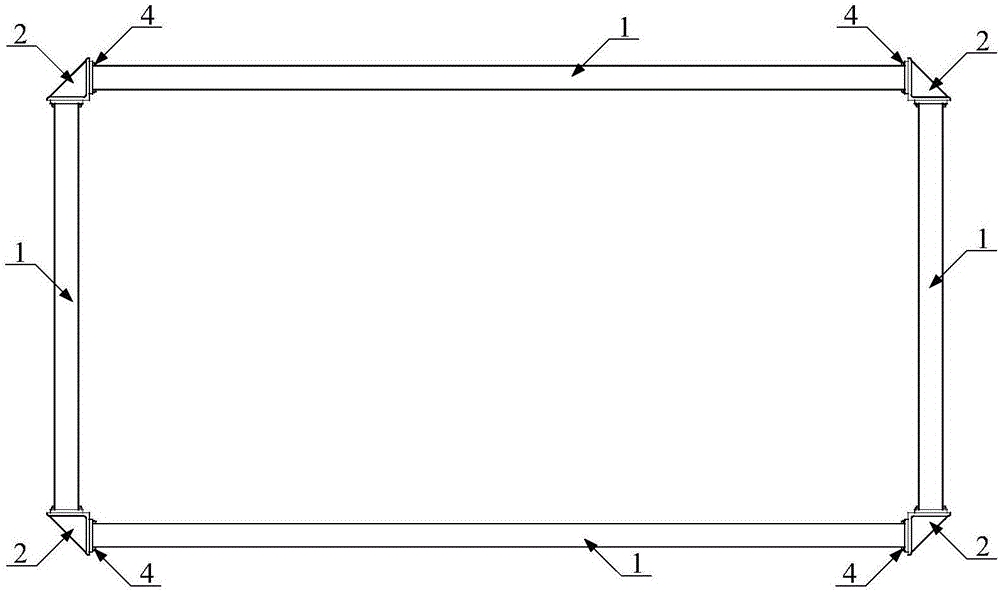

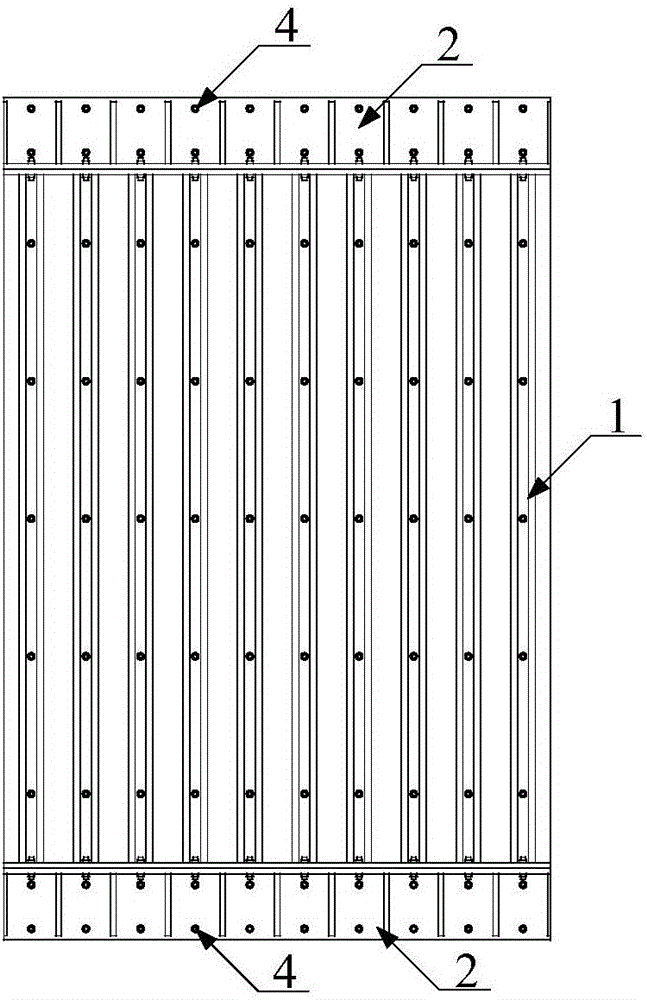

[0046] like Figure 1-1~2-3 As shown, an assembled corrugated steel plate-concrete composite pipe gallery is characterized in that the assembled corrugated steel plate-concrete composite pipe gallery is formed by splicing multiple sections of corrugated steel plate-concrete composite pipe gallery from front to back. The section section of the corrugated steel plate-concrete composite pipe gallery is rectangular or multi-cavity rectangular.

[0047] like Figure 1-1~1-3 As shown, the rectangular cross-section assembled corrugated steel plate-concrete composite comprehensive pipe gallery is connected by high-strength bolts 4 by four corrugated steel plate-concrete composite structures 1 located on the four sides of the rectangular cross-section and four connecting angle steels 2 located at the four corners of the rectangular cross-section com...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap