Hanging hook assembling equipment

A technology for assembling equipment and workstations, applied in mechanical equipment, transportation and packaging, conveyor objects, etc., can solve the problems of low efficiency, low accuracy, and high scrap rate, and achieve improved efficiency, high precision, and less scrap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

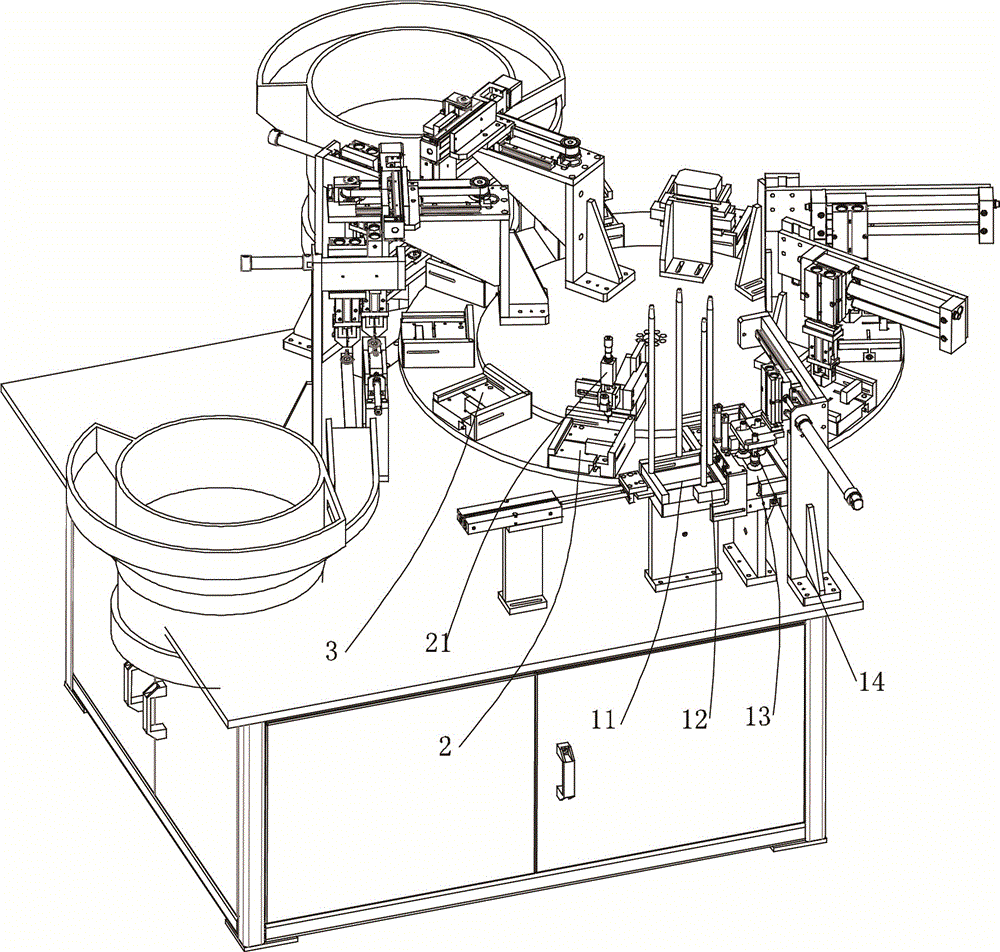

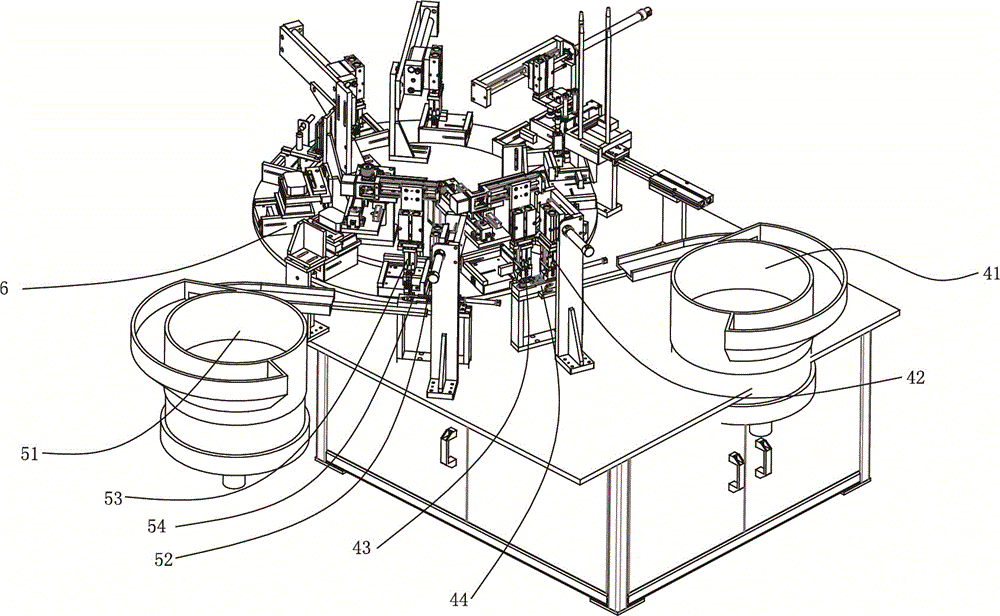

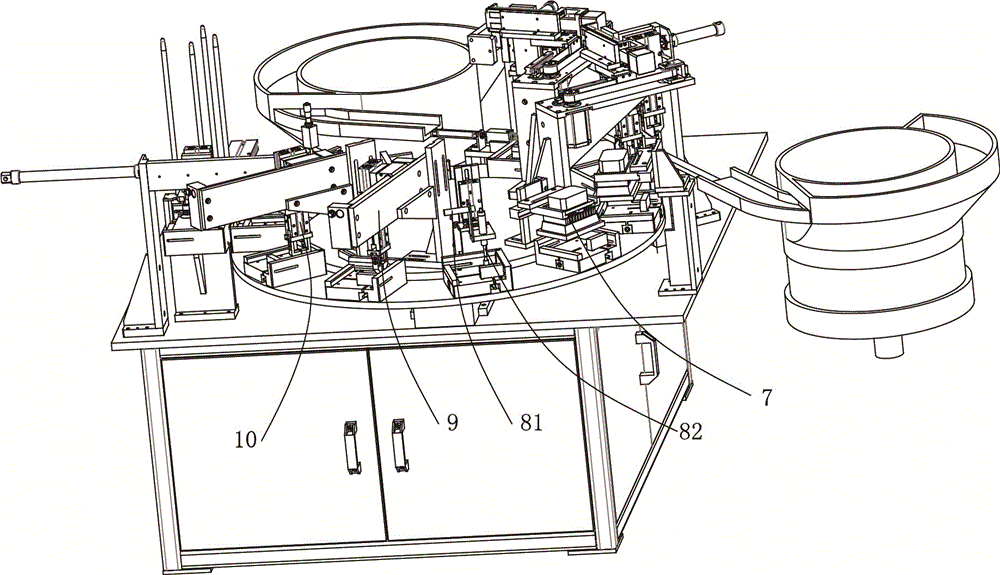

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] A hook assembly device, characterized in that it includes a turntable, and ten stations are uniformly arranged on the turntable, and the ten stations are respectively the first station 1, the second station 2, the third station 3, The fourth station 4, the fifth station 5, the sixth station 6, the seventh station 7, the eighth station 8, the ninth station 9, the tenth station 10, the above ten stations All are fixedly provided with mold cavities for accommodating hooks and non-adhesive panels, said mold cavities are provided with baffles, said first station 1 is a non-adhesive panel feeding mechanism, said second station Position 2 is the glue feeding mechanism, the fourth station 4 is the hook A feeding mechanism, the fifth station 5 is the hook B feeding mechanism, and the sixth station 6 is the primary ultraviolet irradiation mechani...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap