Jet-vane simple load simulation and testing device for thrust vector engine

A technology of thrust vectoring and testing equipment, which is applied in the direction of engine testing, jet engine testing, gas turbine engine testing, etc. It can solve problems such as high price, ablation of testing equipment, unreliable thermal protection safety performance, etc., to reduce processing and Maintenance cost, reduced test cost, stable test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

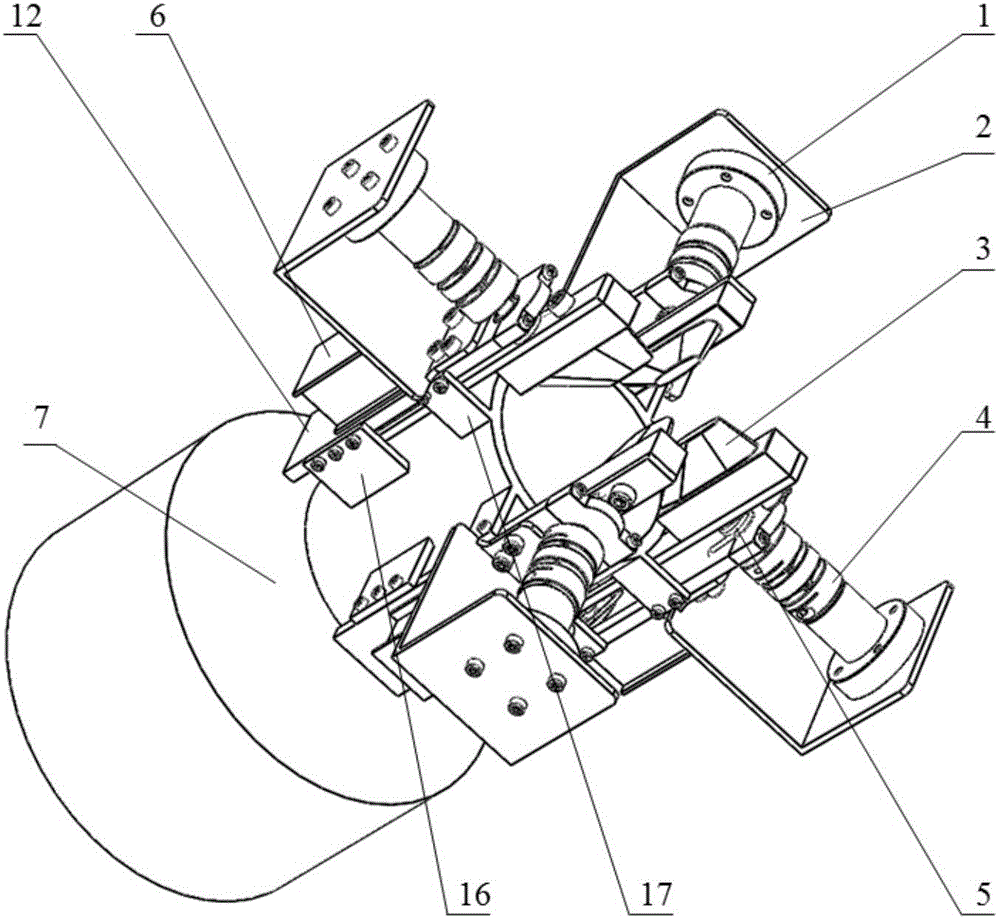

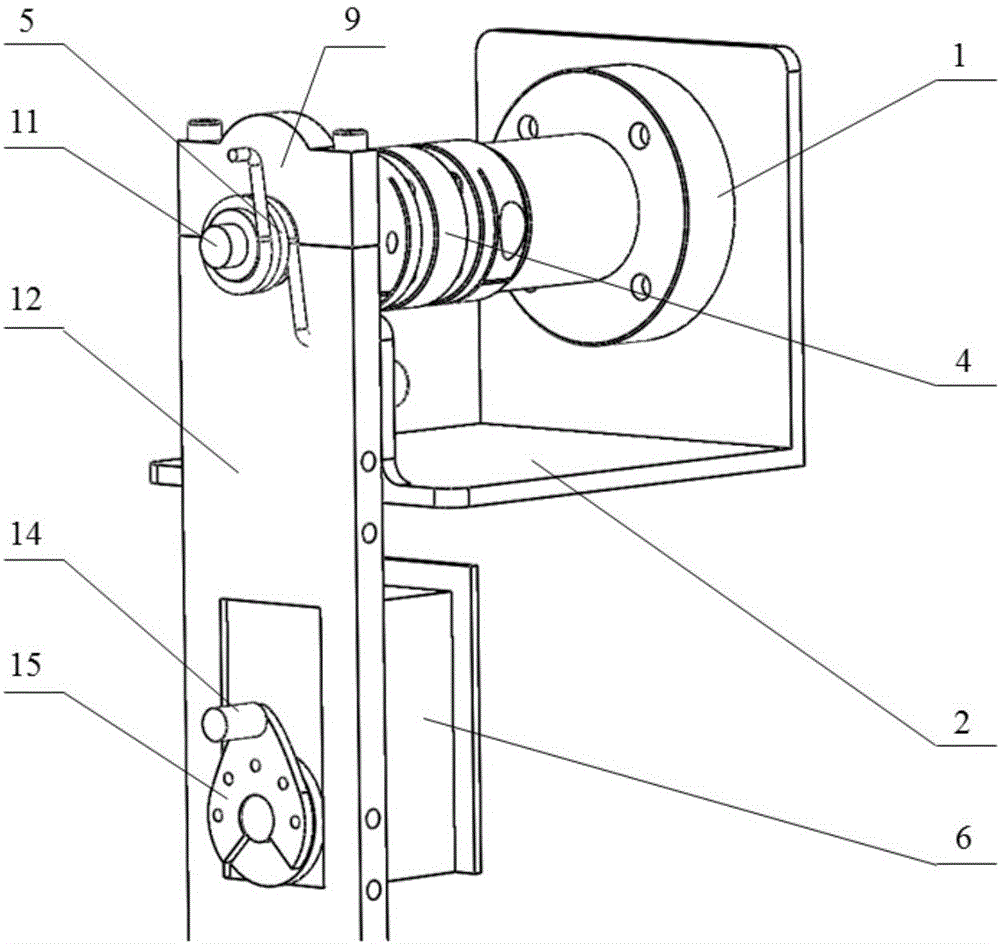

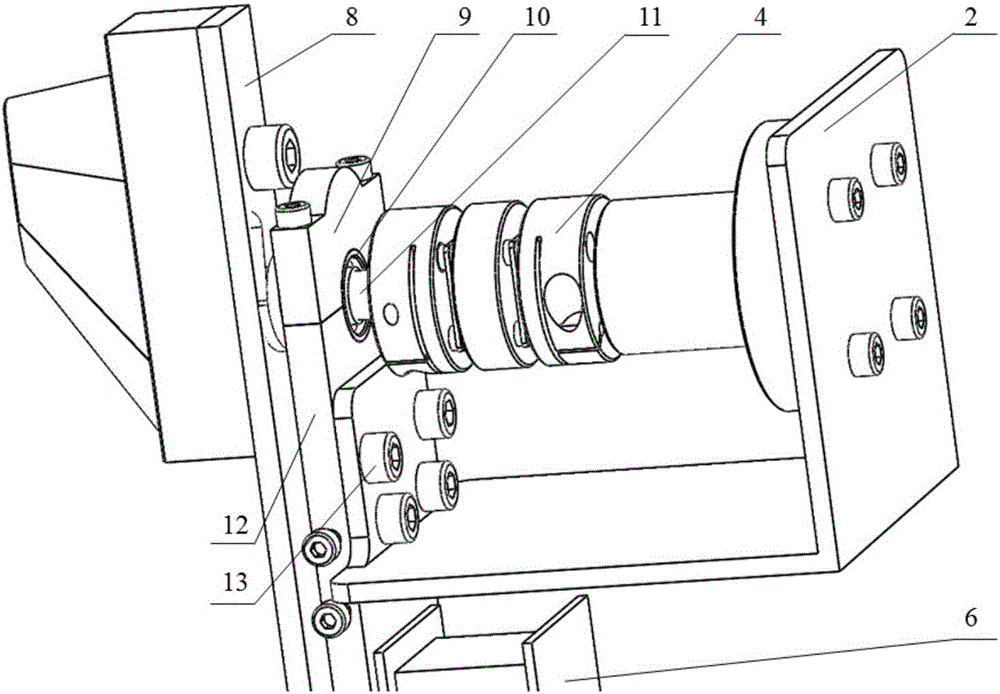

[0016] to combine Figure 1 to Figure 4 , The invention relates to a simple simulation load and testing device of a thrust vectoring engine gas rudder, comprising an improved thrust vectoring engine nozzle, four steering gear transmission load mechanisms and four testing devices.

[0017] The improved thrust vectoring engine nozzle comprises a thrust vectoring engine nozzle, four groups of first rectangular plate groups and four groups of second rectangular plate groups; Annular distribution, each group includes two first rectangular plates parallel to each other, four second rectangular plate groups are distributed annularly along the expansion section of the nozzle of the thrust vectoring engine, each group includes two second rectangular plates parallel to each other, The first rectangular plate group and the second rectangular plate group are in one-to-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com