LED screen test power supply control circuit and method for accurately quantifying power-on timing

A power-on sequence and power test technology, applied to static indicators, instruments, etc., can solve problems such as inaccurate power-on time, different power-on time, large capacitance error, etc., to improve voltage quality, ripple suppression, power The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

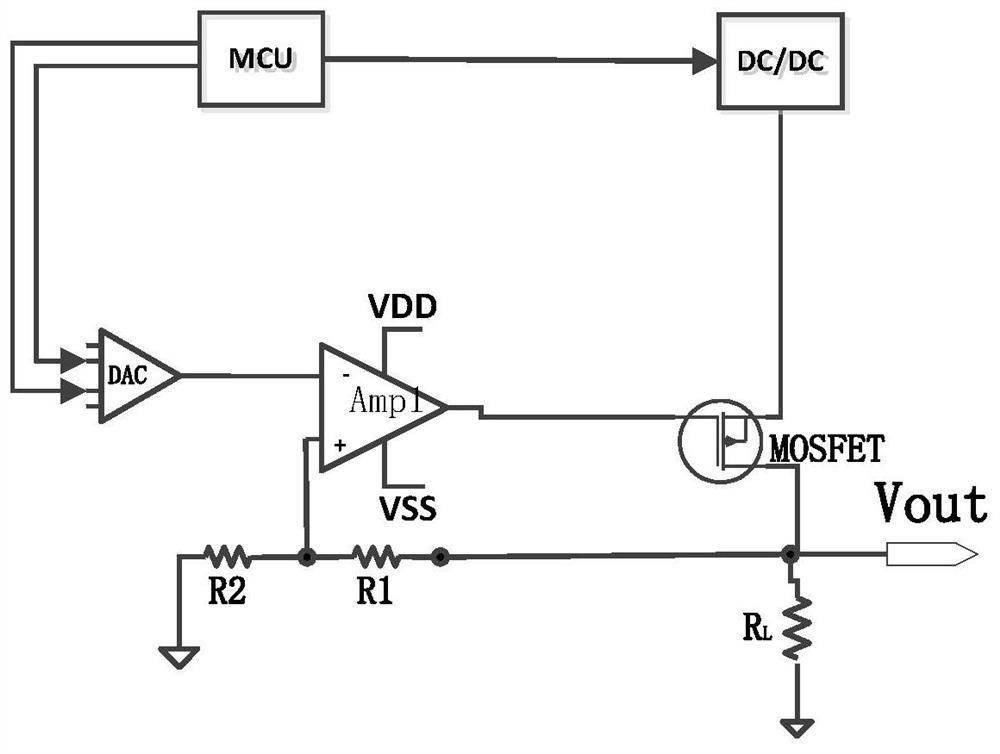

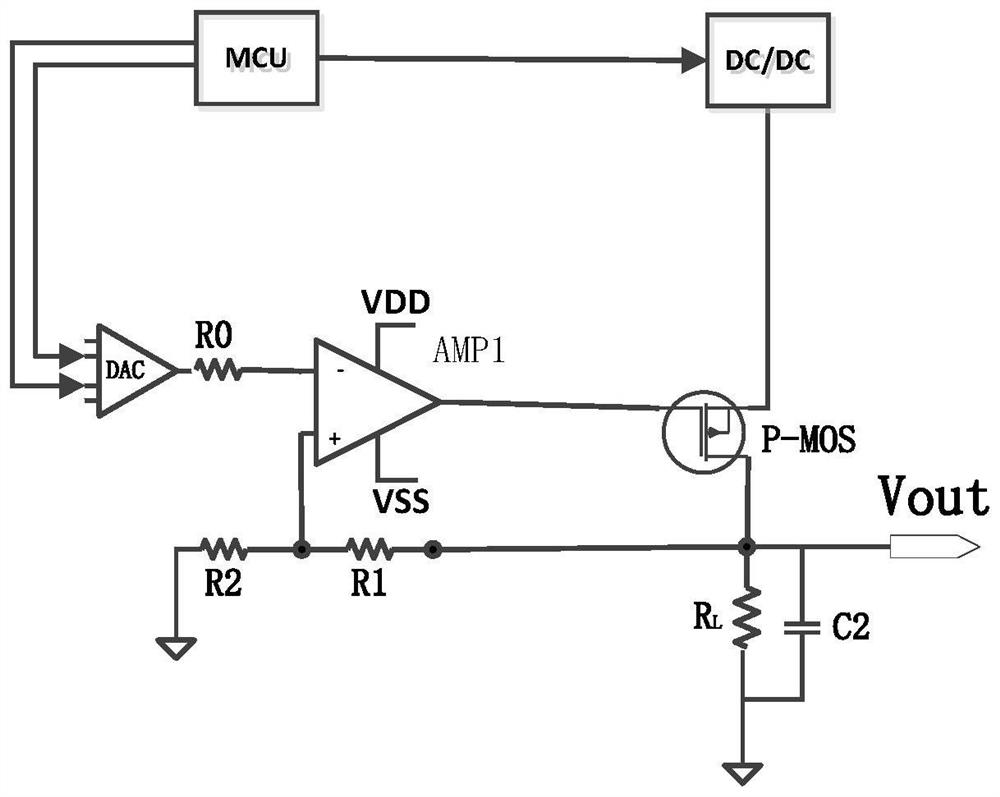

Method used

Image

Examples

Embodiment approach

[0039] The present invention also proposes a method for accurately quantifying the power-on sequence of the LED screen to test the power supply control circuit, which is applicable to the above four implementation modes, and specifically includes the following steps:

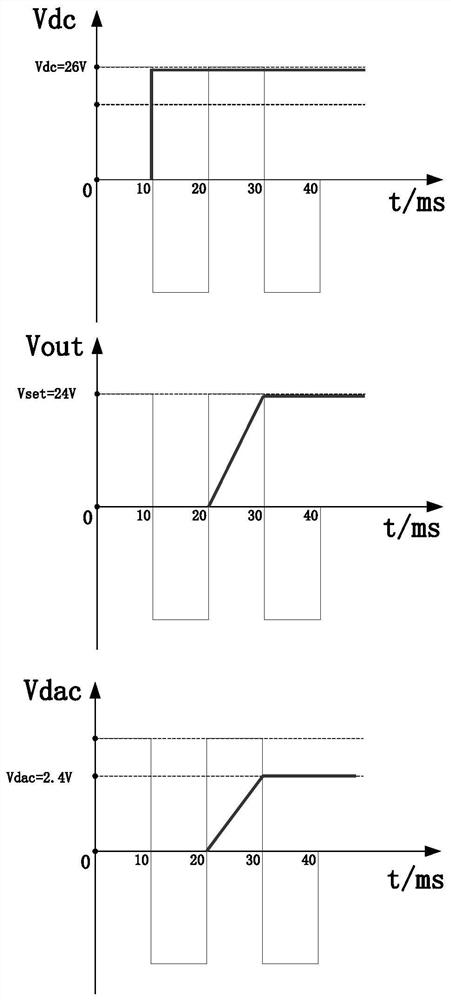

[0040] 1) Set the output voltage Vdc of the DC / DC power supply module according to the value of the output voltage Vout, the voltage value required by the LED screen power supply = output voltage Vout; the output voltage Vdc of the DC / DC power supply module = output voltage Vout + voltage difference, the voltage difference is not greater than 2V.

[0041] 2) Set the output value Vdac of the DAC digital-to-analog converter according to the value of the output voltage Vout and the amplification ratio b, Vout=b*Vdac, and set the waveform slope a according to the power-on time Tset required by the LED screen power supply, a=Vdac / Tset .

[0042] 3) The MCU outputs the voltage to the DC / DC power module, and outputs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com