Level conversion circuit

A technology for converting circuits and levels, applied in logic circuits, logic circuit connection/interface layout, electrical components, etc., can solve problems such as inappropriate high-speed and low-power circuits, and achieve no static power consumption and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

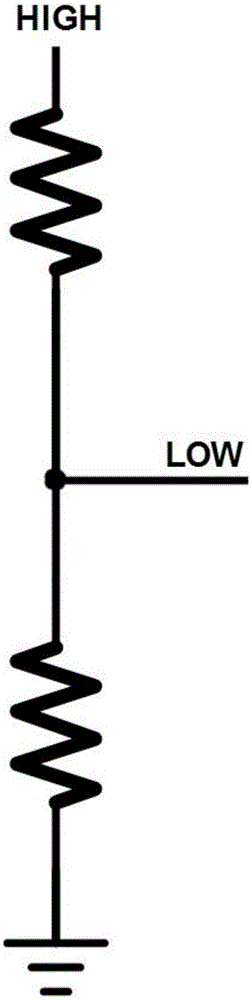

[0022] The invention overcomes the shortcomings of the existing solutions and provides a brand-new level conversion solution from a high-voltage domain to a low-voltage domain. A low withstand voltage device is used to shift the external input high-level voltage to a low-level voltage for use by the internal circuit, so that the internal circuit can work in the low-voltage domain. Using a low-voltage transistor with a relatively thin gate oxide can not only reduce the chip area but also work at a higher frequency without paying for additional mask layers.

[0023] Above-mentioned purpose of the present invention is achieved through the following technical solutions:

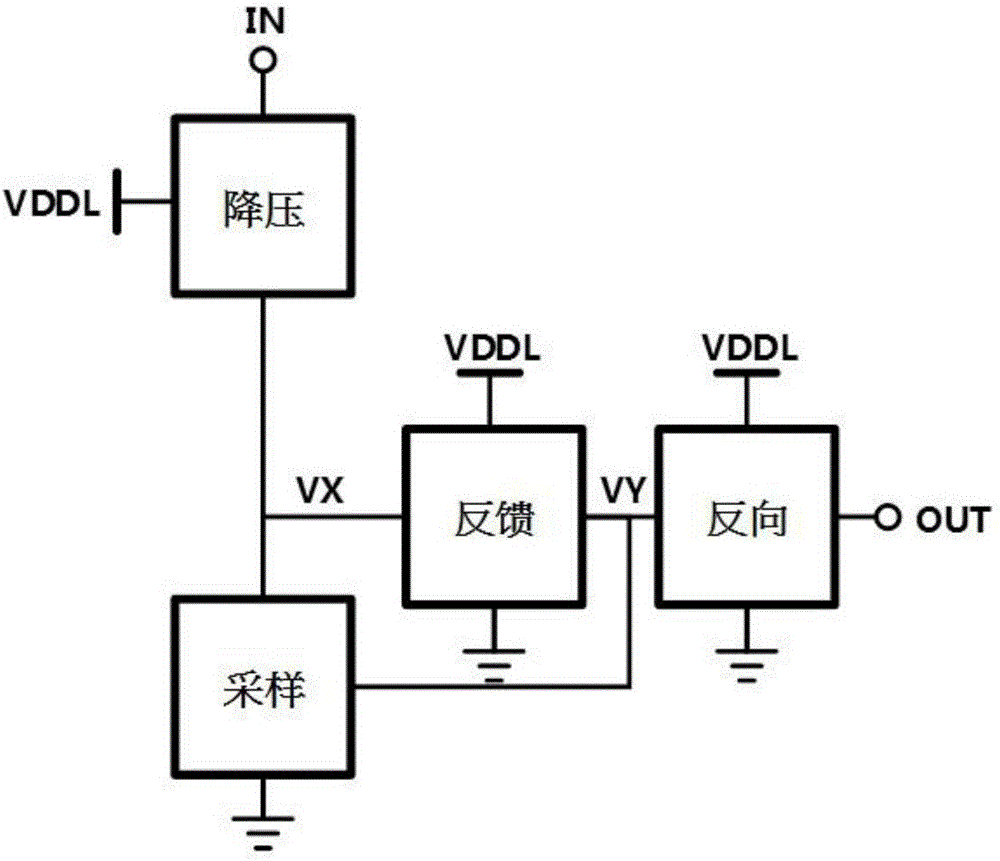

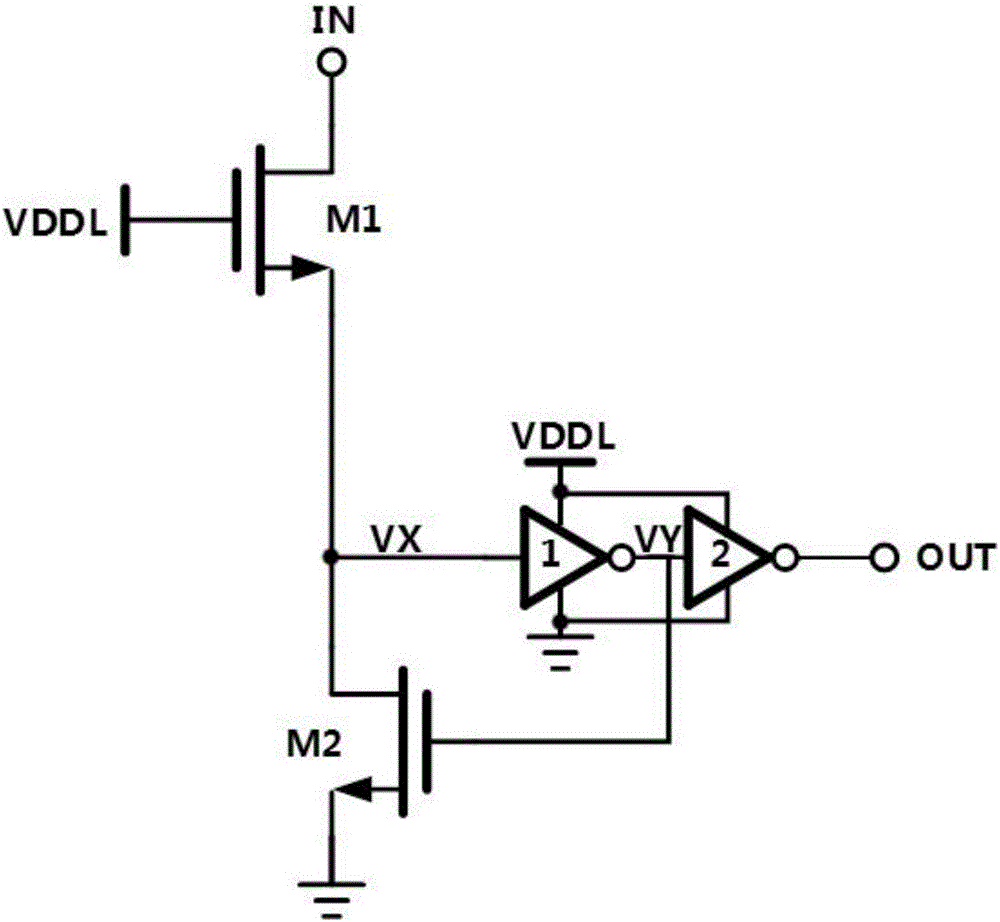

[0024] Such as figure 2 As shown, the level conversion circuit includes a step-down module, a feedback module, a reverse module and a sampling module;

[0025] The step-down module includes the input port IN of the level conversion circuit, and also includes the power port VDDL and the output port; the transis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com