Health monitoring system and method for prefabricated reinforcement sleeve connecting piece

A technology of health monitoring system and steel sleeve, applied in the direction of measuring devices, instruments, etc., can solve the problems of impact, inconvenient original structure safety, etc., and achieve the effect of avoiding complexity and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is described in further detail below in conjunction with accompanying drawing:

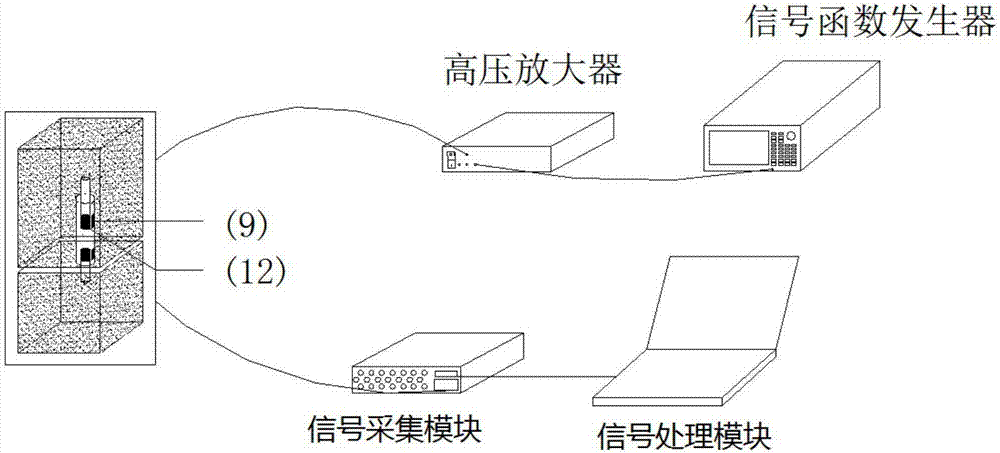

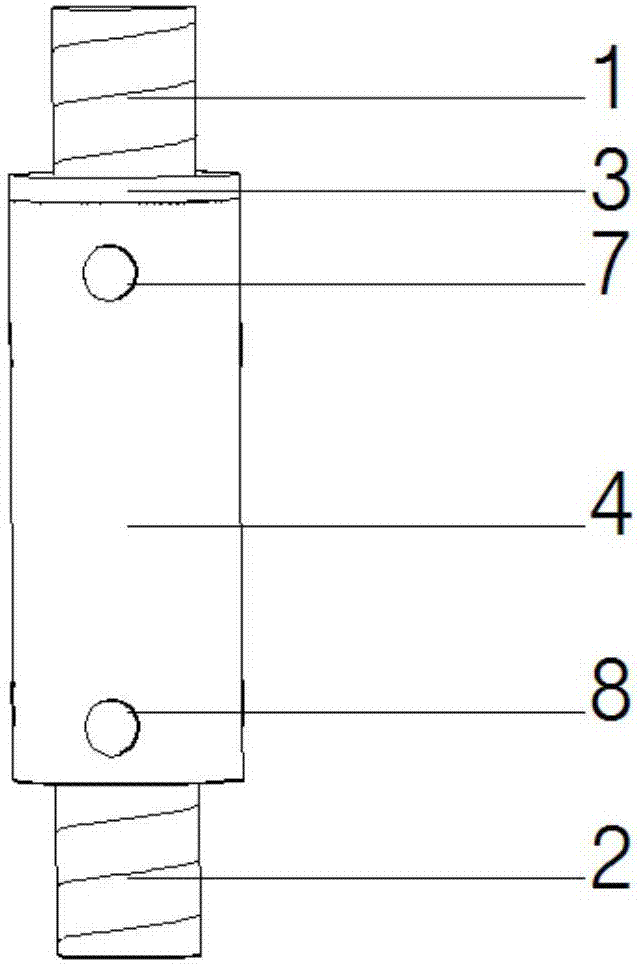

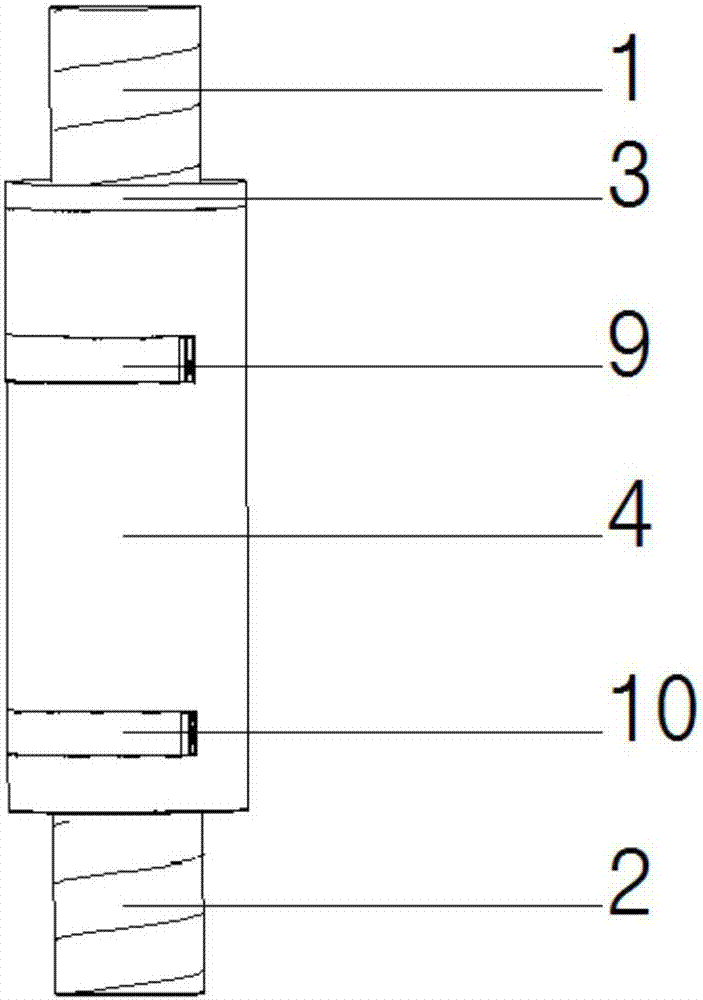

[0057] like Figure 1 to Figure 8 As shown, a health monitoring system for prefabricated steel sleeve connectors includes a steel bar sleeve body 4 for connecting pre-embedded steel bars 2 and inserting steel bars 1. The steel bar sleeve body 4 is a central structure, and the embedded steel bars 2 and inserted steel bar 1 respectively extend into the steel bar sleeve body 4 from both ends of the steel bar sleeve body 4, and fix the pre-embedded steel bar 2 and the inserted steel bar 1 by pouring mortar 11 into the steel bar sleeve body 4, and the pre-embedded steel bar 2 is set A lower three-way piezoelectric ceramic sensor 13 is installed at one end of the steel bar sleeve body 4. The lower three-way piezoelectric ceramic sensor 13 is a barrel-packed structure and is set on the end of the pre-embedded steel bar 2, and the inserted steel bar 1 is placed on the steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com