Dry-powdered cheese compositions with naturally-derived color blends, method of making and cheese product

A colorant and composition technology, applied in the field of powdered cheese composition, can solve the problems of uneven color of cheese sauce, lack of overall taste of cheese sauce, changing the taste of cheese sauce, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

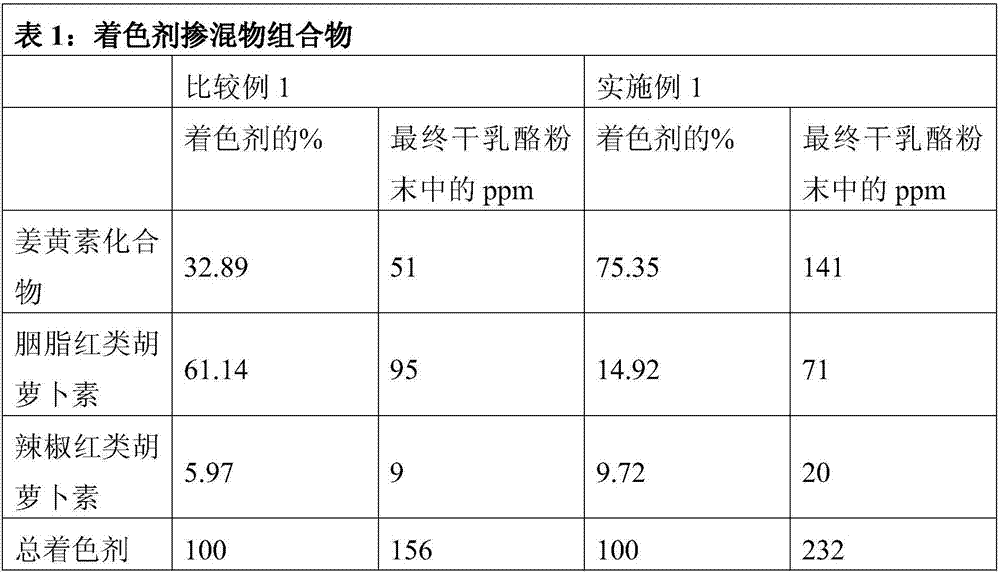

[0036]Two powdered cheese compositions were made and spray dried in a continuous cooker. Each powdered cheese composition was prepared by mixing various cheese ingredients with cheese and emulsifying salt in a cooker. Initially, the mixture was heated to 175°F. Then, the wet whey blend was added to each mixture. The colorant blend of the comparative example was added to the first mixture (Comparative Example 1 in Table 1), while the colorant blend according to various embodiments described herein was added to the second mixture (Table 1 Example 1) in 1. The pigments provided in Table 1 will be in % by weight of the colorant, and will be in ppm based on the weight of each of the powdered compositions of Comparative Example 1 and Example 1.

[0037]

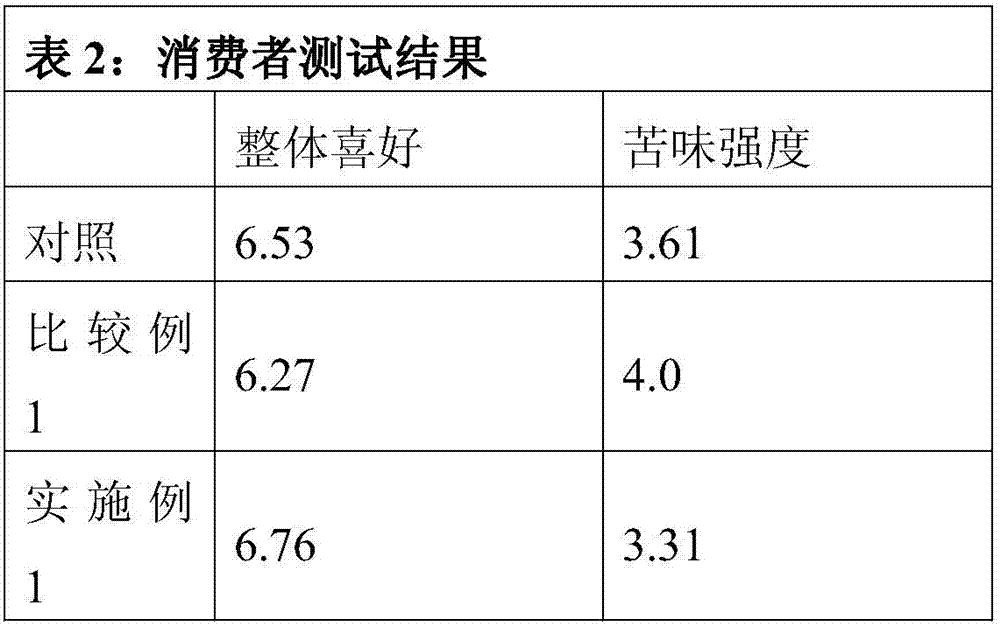

[0038] Bring the mixture to 180°F. Citric acid was added to each slurry as a pH adjuster. Each slurry was then heated to 185°F and held for 2 minutes to pasteurize. The slurry is then cooled to below about 80°F and spray d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com