Pipe joint

A technology of pipe joints and nozzles, which is applied in the field of pipe joints, can solve the problems of labor and other issues, and achieve the effect of safe work and easy connection operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

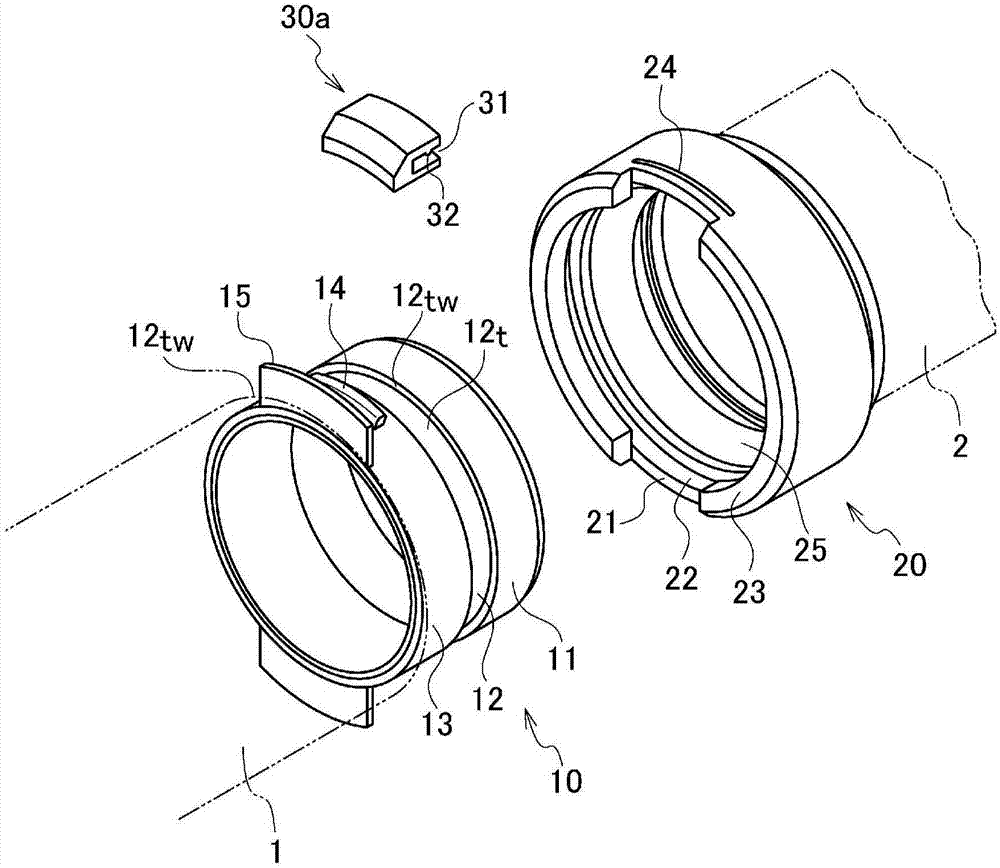

[0035] The pipe joint of the present invention is used to connect one pipe (hereinafter referred to as the first pipe body 1 . figure 1is shown by a double-dotted line. ) and another pipe (hereinafter referred to as the second pipe body 2. It is also shown with a two-dot dash line.).

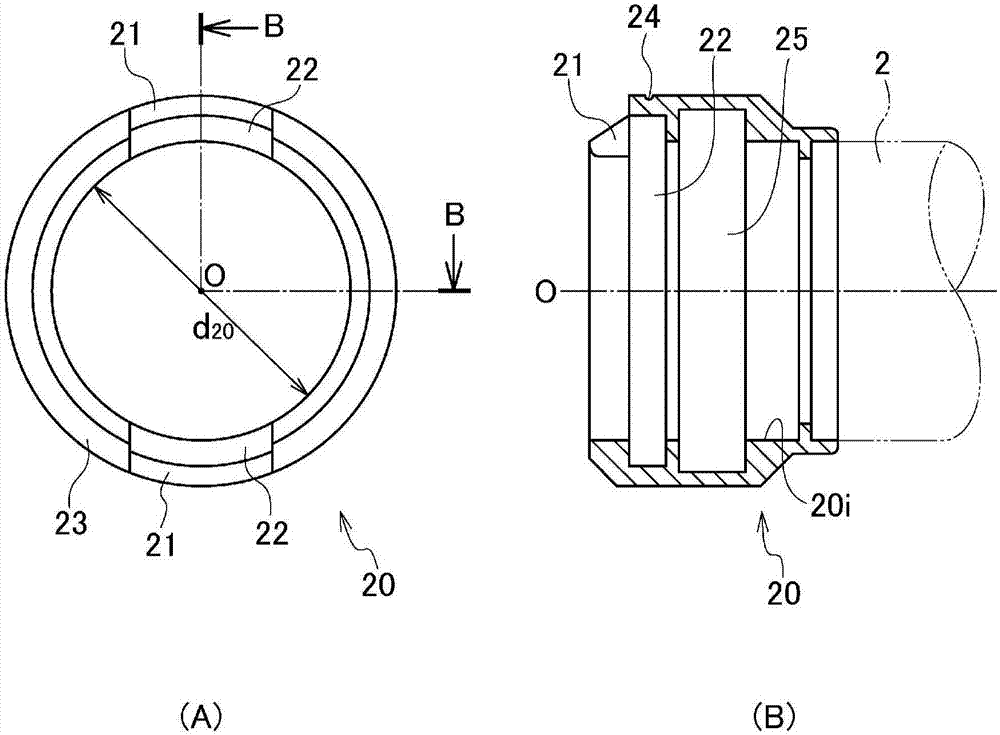

[0036] Figure 1~4 (remove figure 2 (Except for (B)) shows the pipe joint of Example 1. The pipe joint mainly includes a first sleeve 10 connected to the first pipe body 1 and a second sleeve 20 connected to the second pipe body 2 and having an opening capable of accommodating the first sleeve 10 . Moreover, the connection between the first and second sleeves 10, 20 and the first and second pipe bodies 1, 2 is realized by, for example, welding, bonding or other known connection methods.

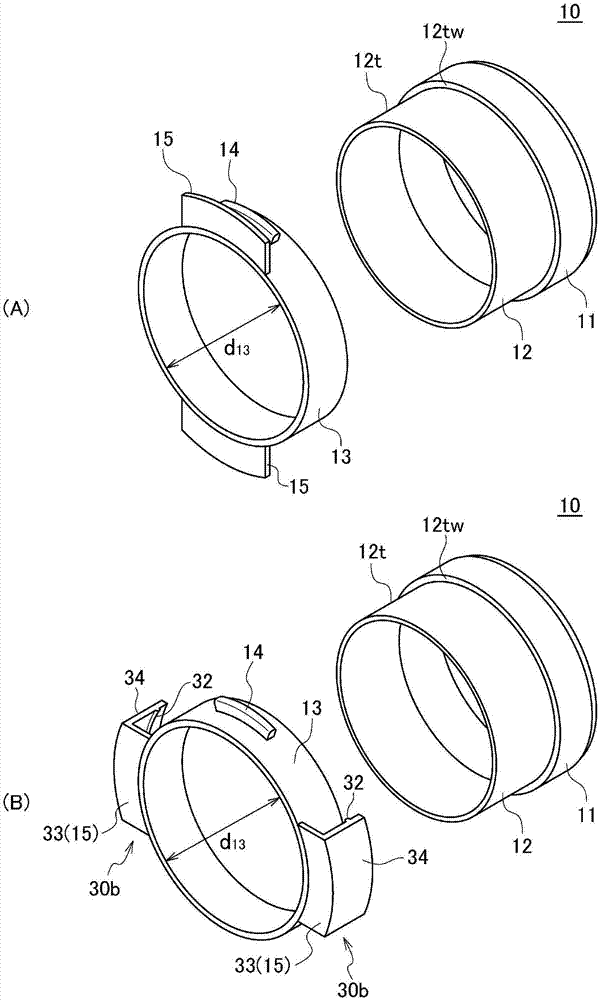

[0037] The first sleeve 10 such as Figure 4 As shown in (A), it may also include a plurality of cylindrical bodies (the first, second, and third nozzles 11, 12, and 13 in this embodiment). and, figure...

Embodiment 2

[0047] Figure 5 (A) to (D) show the pipe joint of Example 2. The pipe joint of Embodiment 2 is also the same as Embodiment 1, and has a first sleeve 10 connected to the first pipe body 1 and a second sleeve 20 connected to the second pipe body 2 . The structures of the first sleeve 10 and the second sleeve 20 in the second embodiment are substantially the same as those of the components 10 and 20 adopted in the first embodiment, and will not be described again. Here, the difference between Embodiment 2 and Embodiment 1 lies in the structure of the anti-loosening component 30b and the position of the manipulation member provided on the outer peripheral surface of the third nozzle 13, and the following two points will be explained emphatically. and, figure 2 (B) is the perspective view of the 3rd nozzle 13 of Example 2, and the 1st sleeve 10 including the fall-off preventing member 30b provided thereon.

[0048] For example, if figure 2 As shown in (B), the anti-loosening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com