Candle grinding machine

A technology of grinding machine and candle, applied in decorative arts, engraving and other directions, can solve the problems of unsmooth surface of candle, increase labor intensity, low work efficiency, etc., and achieve the effect of strong three-dimensional effect, reduced labor intensity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

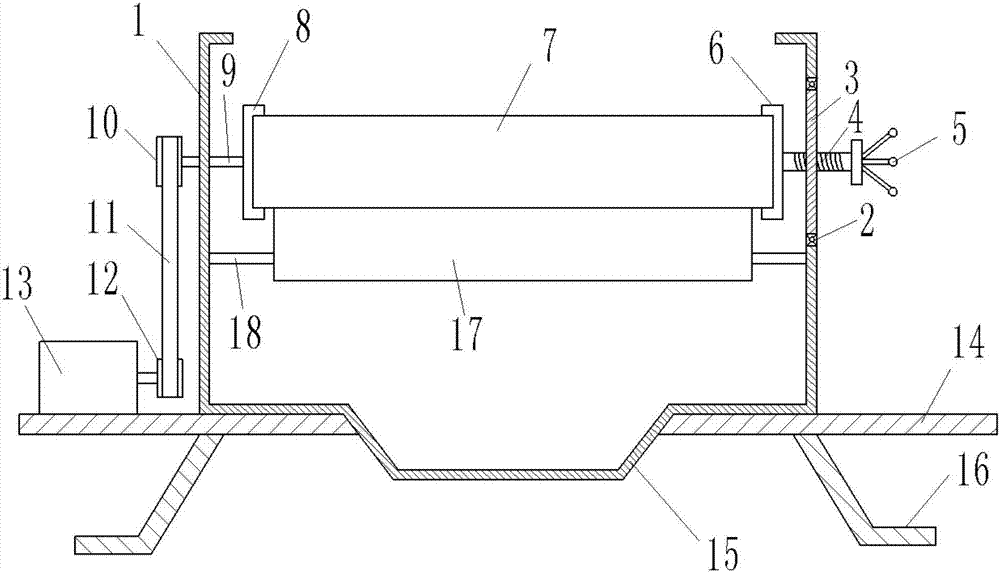

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0013] see figure 1 , in an embodiment of the present invention, a candle burner includes a main frame 1, a bearing 2 is installed on the upper right side of the main frame 1, the bearing 2 is internally connected to a center wheel 3, and the middle part of the center wheel 3 is threadedly connected to a thread Rod 4, the right end of the threaded rod 4 is equipped with a locking turntable 5, the left end of the threaded rod 4 is equipped with a right splint 6, the left end of the right splint 6 is connected to the candle 7, and the left side of the candle 7 is connected to the right end of the left splint 8 On the surface, a rotating shaft 9 is installed on the left side of the left splint 8, and the rotating shaft 9 is slidingly connected with the left side plate of the main frame 1. The left end of the rotating shaft 9 is connected to the large ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap