Feeding device capable of feeding on bamboo mat weaving machine and utilization method of feeding device

A technology for weaving machines and bamboo mats, applied in conveyor control devices, grinding/polishing safety devices, packaging, etc., can solve problems such as damage, and achieve the effect of avoiding environmental pollution and equipment idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

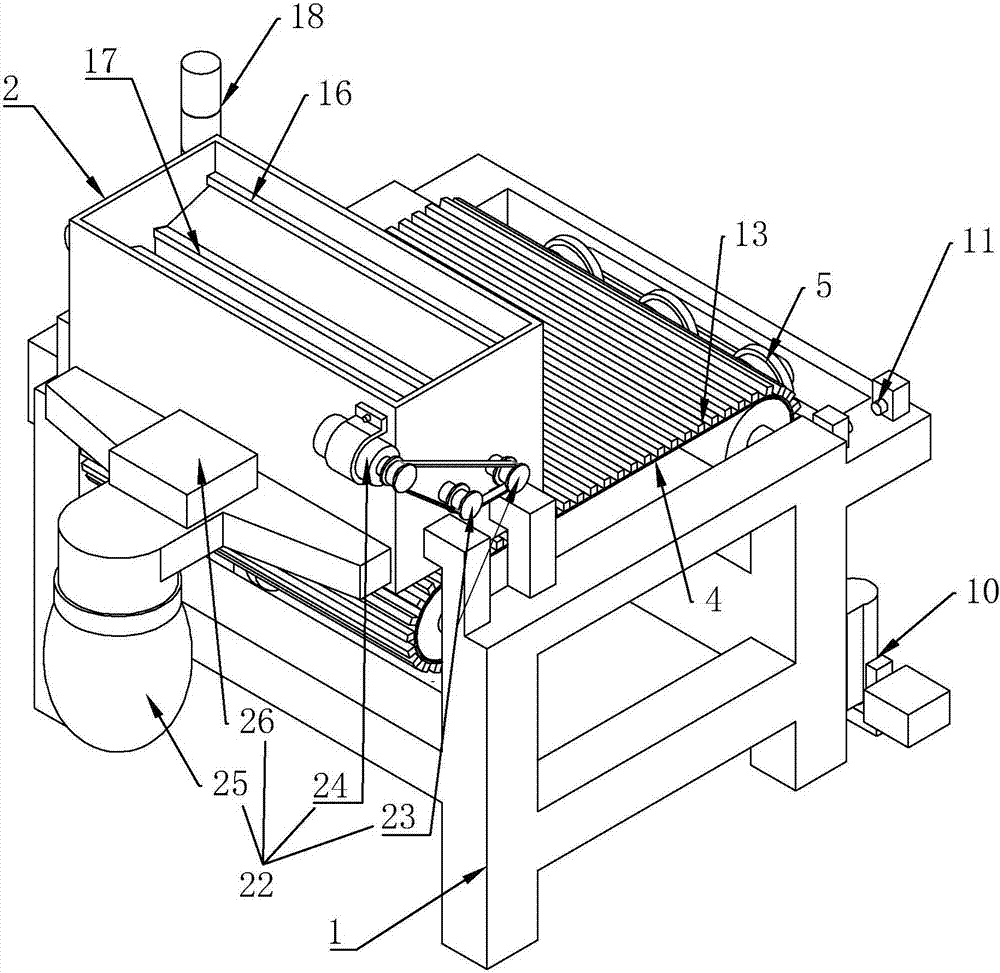

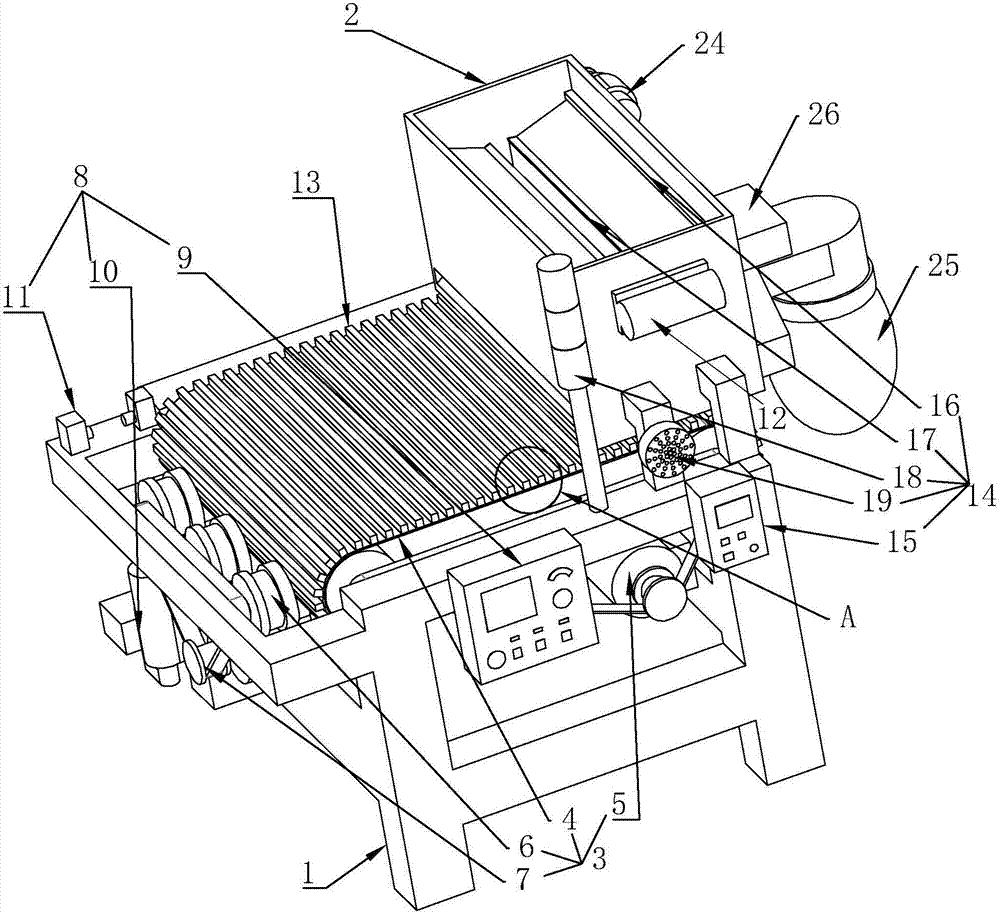

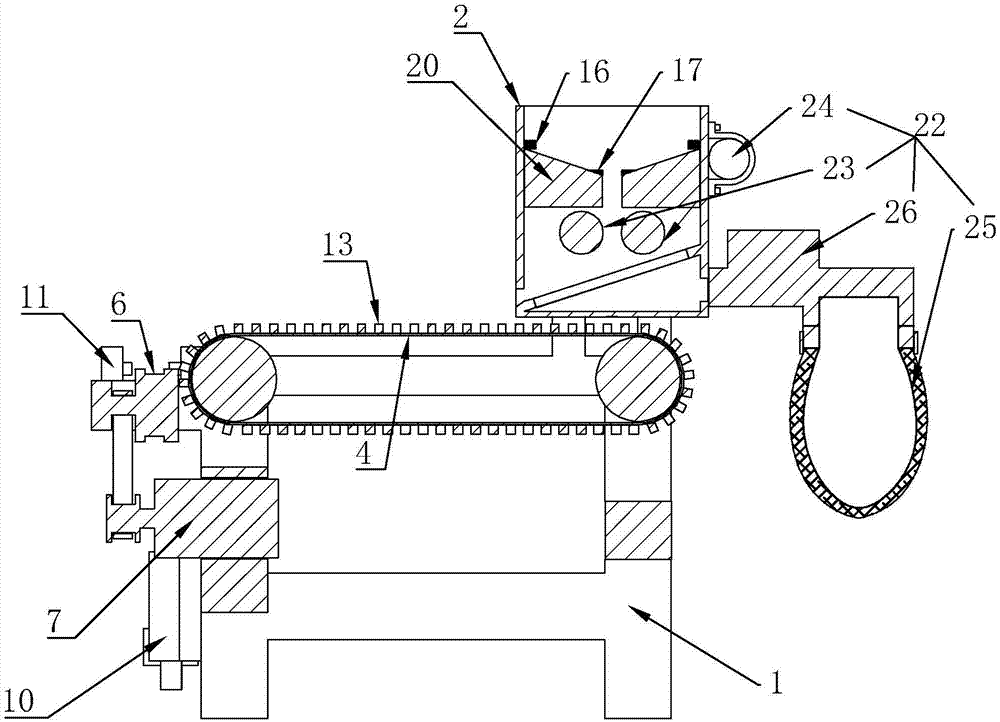

[0030] refer to Figures 1 to 4 As shown, a kind of feeding device that can carry out feeding to bamboo mat knitting machine of the present embodiment, it comprises frame 1, discharge box 2, polishing mechanism 22, early warning device 14, transmission mechanism 3 and control device 8, The discharge box 2 is arranged on the upper end of the frame 1, the transmission mechanism 3 is arranged between the discharge box 2 and the frame 1, and is used to transmit the bamboo strips placed in the discharge box 2, and the control device 8 It is arranged on the frame 1, and is used to control the bamboo strips placed on the transmission mechanism 3 to enter the feeding port of the bamboo mat weaving machine. The bottom of the discharge box 2 is provided with an outlet for discharging bamboo strips. The early warning Device 14 is arranged on the discharge box 2 and is used to monitor the usage of bamboo strips in the discharge box 2, and gives early warning prompts to workers that the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com