A kind of titanium silicon molecular sieve and its synthetic method and application and a kind of method of cyclic ketone oxidation

A titanium-silicon molecular sieve and synthesis method technology, applied in molecular sieve compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex process, small grain size, insufficient reactivity, etc., and achieve improved selectivity and long service life. , the effect of good catalytic activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the present invention, the purpose of the present invention can be achieved as long as the titanium silicate molecular sieve has the aforementioned characteristics. The synthesis method can be various, as long as the titanium silicate molecular sieve with the aforementioned characteristics can be synthesized. For the present invention, the titanium silicate is preferred. The silica molecular sieve is synthesized according to the following method, which includes:

[0033] In the presence of an aqueous solvent, the silicon source, titanium source and alkali source are mixed and then hydrothermally crystallized under airtight conditions to recover the titanium silicon molecular sieve; wherein the hydrothermal crystallization sequentially undergoes stages (1) and stages ( 2) and stage (3), stage (1) is crystallization at 80-120°C, stage (2) is heated to 180-220°C for crystallization, stage (3) is cooled to 140-180°C for crystallization.

[0034] According to a preferred embod...

Embodiment approach

[0037] According to a preferred embodiment of the present invention, the molar ratio of silicon source: titanium source: alkali source: water is 100: (0.5-5): (10-50): (500-5000), preferably 100: (2 -4): (15-35): (1000-3000) where the silicon source is SiO 2 Calculated, titanium source is TiO 2 Calculated, alkali source is N or OH - meter.

[0038] According to the method of the present invention, the water-containing solvent basically contains water, and a co-solvent can also be added as required. In the embodiment of the present invention, the water-containing solvent is water.

[0039] In the present invention, the silicon source may be an inorganic silicon source and / or an organic silicon source.

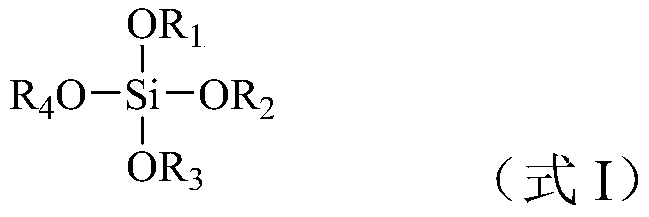

[0040] Specifically, the organosilicon source can be, for example, one or more selected from the silicon-containing compounds represented by formula I,

[0041]

[0042] In formula I, R 1 , R 2 , R 3 And R 4 Each C 1 -C 4 The alkyl group, including C 1 -C 4 The straight chain alkyl and ...

Embodiment 1

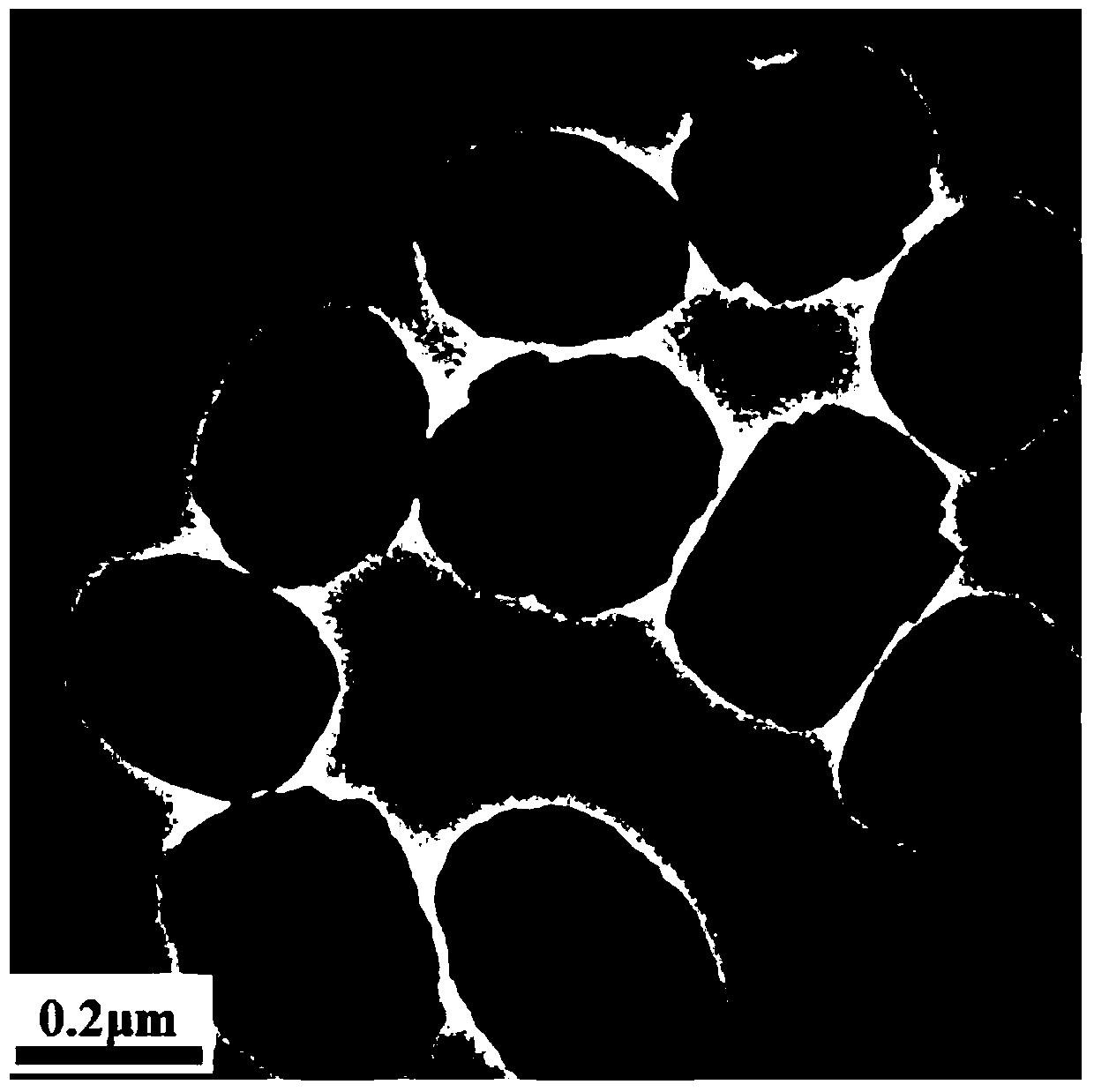

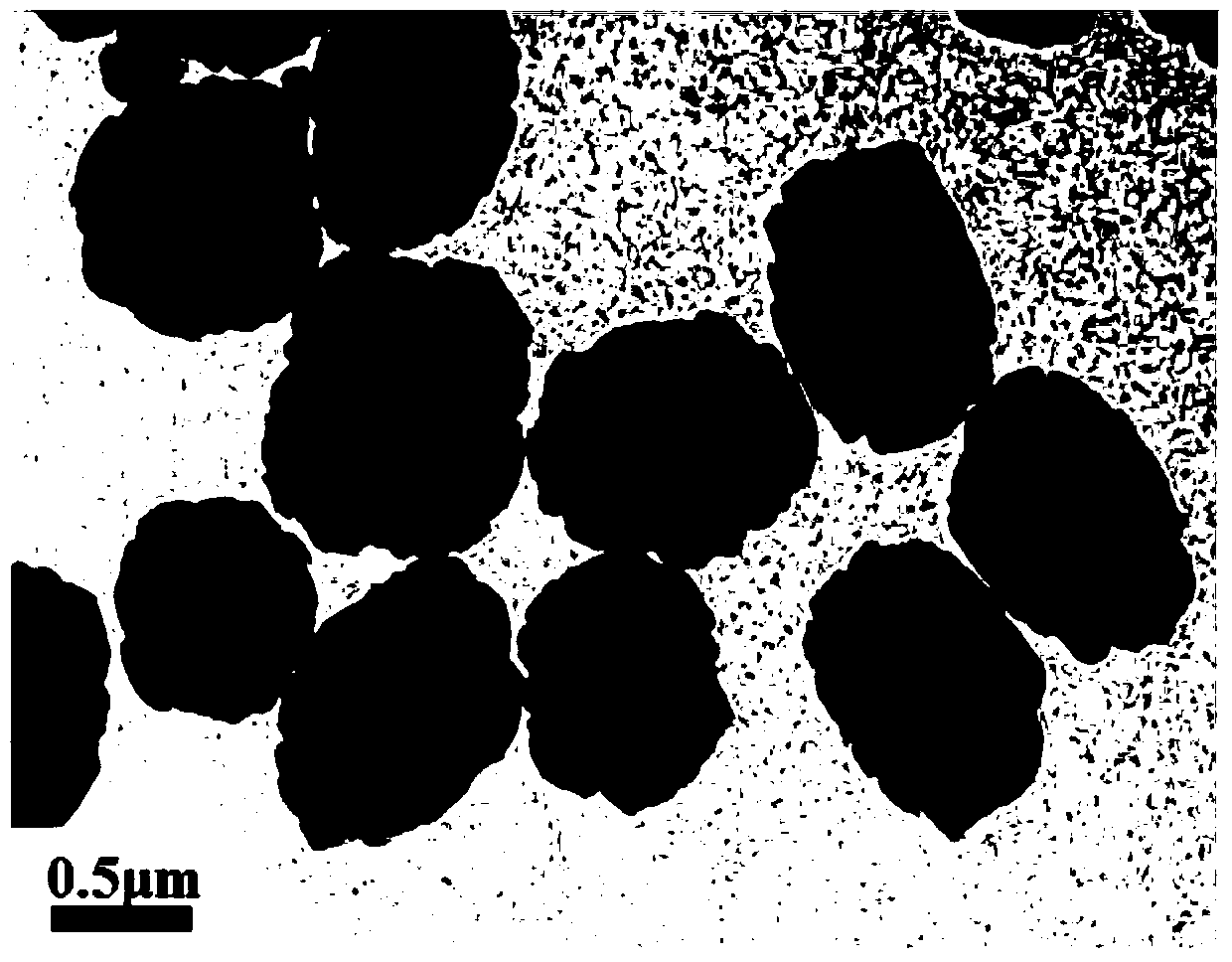

[0090] Add 20 grams of silicon source tetraethylorthosilicate into the tetrapropylammonium hydroxide aqueous solution and stir and mix uniformly, then add tetrabutyl titanate and mix uniformly to obtain the molar composition: silicon source: titanium source: alkali source: Water=100:2:15:1000 mixture. Place the mixture in a stainless steel sealed reaction kettle, raise the kettle temperature to 100°C at a heating rate of 2°C / min from room temperature and hydrothermally heat it for 24 hours at this temperature, then raise the kettle temperature to 190°C at a heating rate of 15°C / min And hydrothermally treat at this temperature for 6 hours; then reduce the temperature of the kettle to 170°C at a cooling rate of 10°C / min and hydrothermally treat it at this temperature for 48 hours. Finally, after cooling to room temperature and releasing the pressure, the product in the reactor is filtered, After washing, drying and calcination at 550°C for 5 hours, sample A of titanium silicate m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com