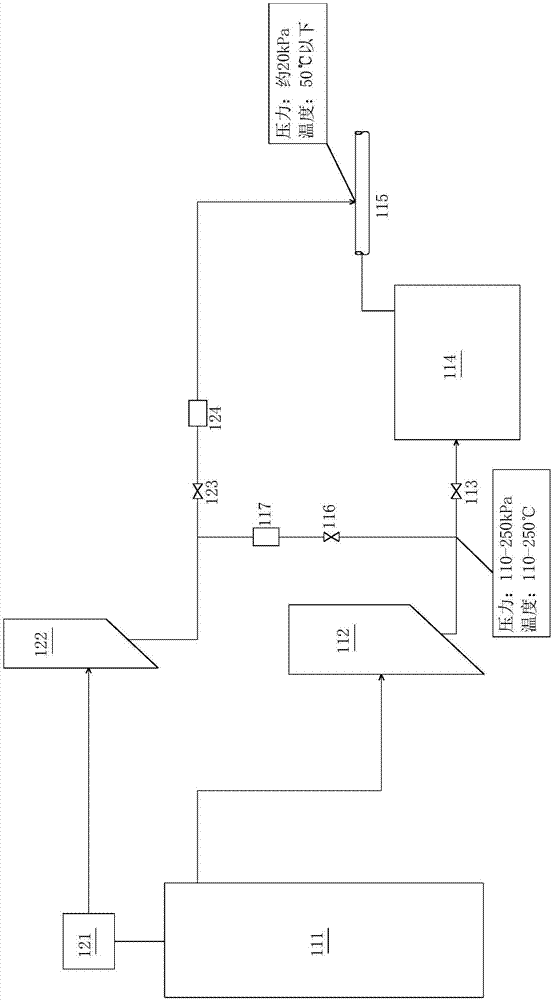

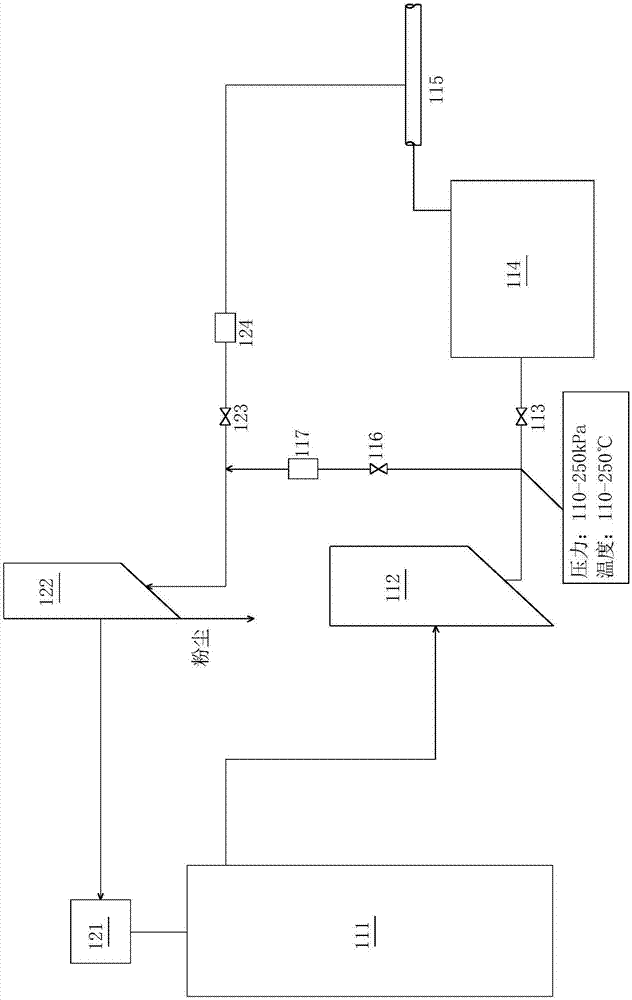

Purification and recovery system for pressure relief exhaust gas of feeding airtight tank of top of blast furnace

A technology of exhaust gas purification and recovery system, which is applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of exhaust gas purification and recovery without pressure relief, and achieve the effects of purification and recovery, cost reduction, and simplification of equipment and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The filter part of the filter used in the gas dust removal device 122 of the blast furnace top feeding airtight box pressure relief exhaust purification recovery system of this embodiment uses a filter bag, and the bag body of the filter bag is made of glass fiber. A gas-permeable support made of cloth and an expanded polytetrafluoroethylene film attached to the inner surface of the gas-permeable support as the filter membrane, the pore structure of the expanded polytetrafluoroethylene film has The dust content is controlled at 5mg / Nm 3 The following filter performance.

[0046] More specifically, the filter bag is provided by the applicant of the present invention with the brand name "Rui Kelin" or "reachclean" filter bag commodity. The bag body of the filter bag includes a breathable support made of glass fiber woven cloth. body and an expanded polytetrafluoroethylene film attached to the inner surface of the gas-permeable support, wherein the pore structure of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com