An all-metal eddy current position sensor and its solution to temperature drift

A solution, eddy current technology, applied in the direction of using electrical devices, instruments, measuring devices, etc., can solve problems such as unsolvable temperature drift, unsuitable for detection, expensive cost, etc., to achieve a wide range of applications, increase market competitiveness, and protect the environment The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operation processes.

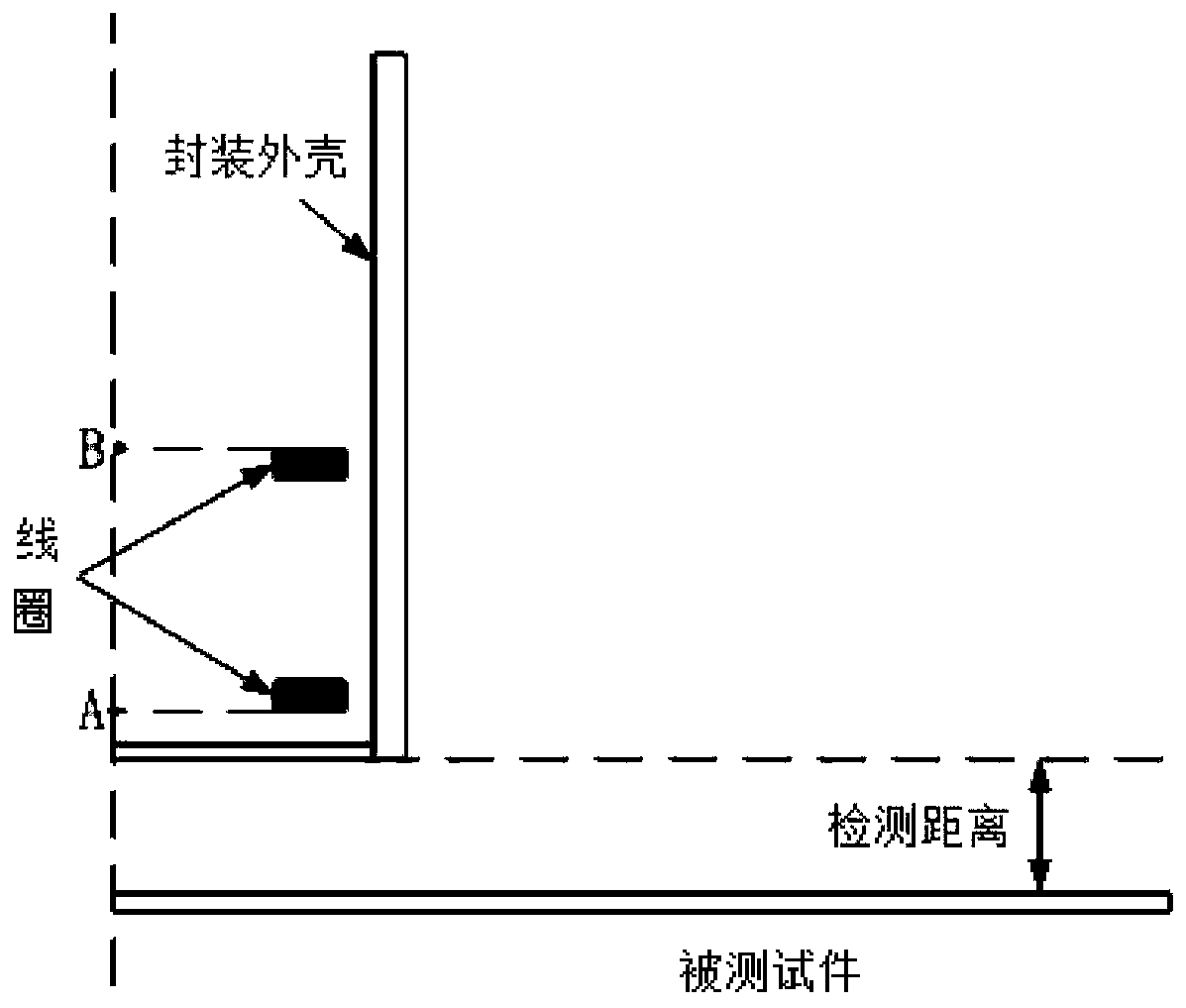

[0048] The all-metal eddy current position sensor adopts the nationally recognized food-grade metal SUS304 stainless steel to package the double-coil structure with the same parameters placed side by side, such as figure 1 As shown, the packaged probe coil is connected to the subsequent processing circuit through wires.

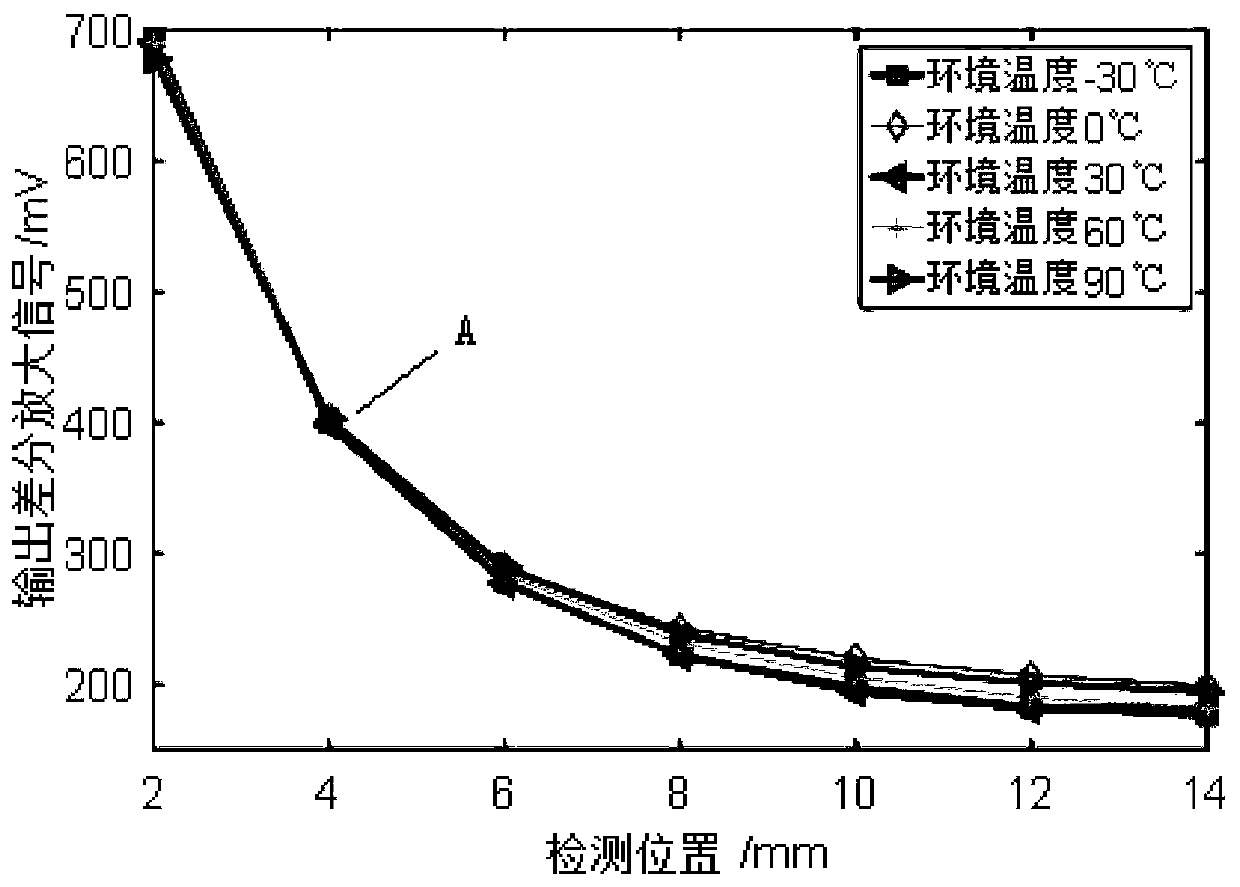

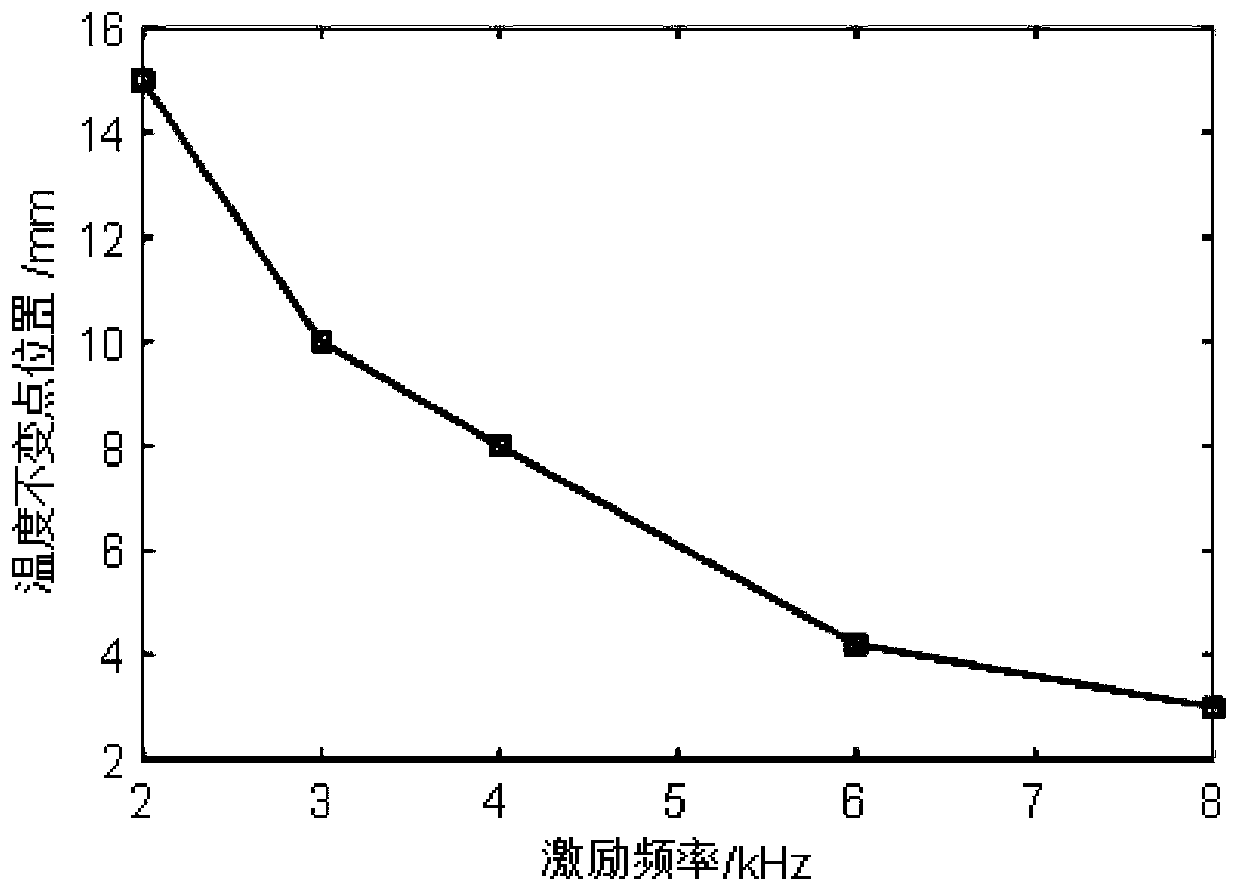

[0049] The all-metal eddy current position sensor to be processed has an excitation frequency range of 0-10kHz, a compensation temperature range of -30-90°C, and a position measurement range of 0-16mm.

[0050] Select the typical values of 2kHz, 3kHz, 4kHz, 6kHz, 8kHz within the excitation frequency range, P=5, select the typical values of -30°C, 0°C, 30°C, 60°C and 90°C within the compensation tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com